Polymer Congress 2018

Polymer Sciences

ISSN: 2471-9935

Page 25

June 04-05, 2018

London, UK

4

th

Edition of International Conference on

Polymer Science and

Technology

T

he breakthrough of flexible electronics depends upon

suitable large-scale manufacturing routes, likely requiring

very low cost, high-throughput processing techniques. Our

approach to development of organic electronics considered

high-speed roll-to-roll processing routes already employed

industrially. We examined their applicability in creating

transistors and circuits. Central to this is the high-throughput

deposition of polymeric dielectric using a vacuum deposition

route compatible with the preferred processing for molecular

semiconductors, metal contacts and ceramic or other

semiconducting active components. This paper will discuss

the control of dielectric properties as determined by processing

parameters during the thin-film deposition and by the surface

segregation of one component of a monomer mixture to

control interfacial properties of the dielectric. The dielectric

performance will be demonstrated in OTFT devices and circuit

elements.

Recent Publications

1. Abbas G et al. (2013) Hysteresis-free vacuum-

processed acrylate-pentacene organic thin film

transistors. IEEE Electron Device Letters. 34(2):268-

270.

2. Ding Z et al. (2013) Improving the performance of

organic thin film transistors formed on a vacuum

flash-evaporated acrylate insulator. Applied Physics

Letters. 103:233301.

3. Abbas G A W (2014) A high-yielding evaporation-

based process for organic transistors based on

the semiconductor. DNTT. Organic Electronics.

15(9):1998-2006

4. Avila Niño J A (2016) Stable organic static random

access memory from a roll-to-roll compatible vacuum

evaporation process. Organic Electronics. 31:77-81

5. Ding Z et al. (2016) Vacuum production of OTFTs

by vapour jet deposition of dinaphtho[2,3-b:2’,3’-f]

thieno[3,2 b]thiophene (DNTT) on a lauryl acrylate

functionalised dielectric surface. Organic Electronics.

31:90-97.

Biography

Hazel E Assender graduated from the University of Cambridge, followed

with a PhD and two years of Postdoc in the Department of Materials Science

& Metallurgy in Cambridge before moving to an academic post in Oxford

University. She has led a research activity in the Department of Materials,

University of Oxford, UK since 1996 with a focus in the area of thin films

and coatings both of polymer materials or onto polymer substrates. Her

research spans fundamental studies of the thin film and near-surface prop-

erties of polymers, through to materials engineering of thin films and device

structures in large area on polymer substrates. Her particular areas of inter-

est include roll-to-roll deposition, gas barriers, photovoltaics, and transistors/

circuits. Her research has a technology-facing approach bringing underpin-

ning scientific understanding to development of materials and technologies

that integrates research relevant to industrial processing such as scale-up of

manufacture with the development of newmaterials and structures.

hazel.assender@materials.ox.ac.ukDeposition and control of polymer dielectrics for OTFTs

Hazel E Assender

University of Oxford, UK

Hazel E Assender, Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-011

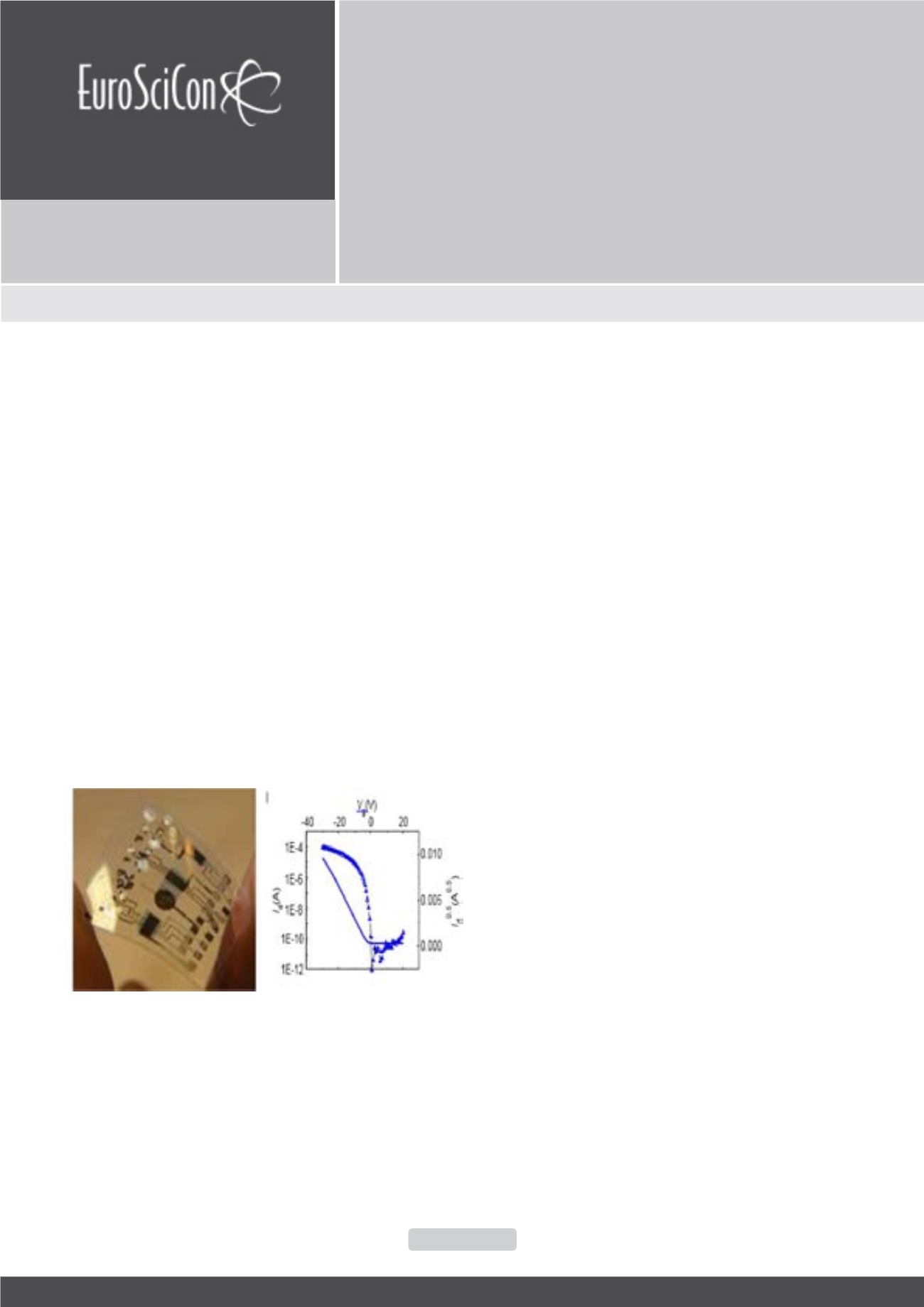

Figure 1:

An array of OTFTand capacitor deviceswith polymer dielectric, and

typical OTFTtransfer curve.