Polymer Congress 2018

Polymer Sciences

ISSN: 2471-9935

Page 31

June 04-05, 2018

London, UK

4

th

Edition of International Conference on

Polymer Science and

Technology

Statement of the Problem:

Commonly, head injuries are

produced by a punctual dynamic force. When fractures are

produced, they are followed by tensile loads that generate

more fractures on other cranium areas. Prostheses have

the objective to patch a damaged area and heal the injury.

Nowadays, research is focused on customized prostheses and

there is no interest to develop a standard product to produce in

mass series. Incremental Sheet Forming (ISF) is a technology

useful to manufacture small batch or one-of-a-kind sheet

products. This paper presents the use of ISF with the aim of

manufacturing cranial prostheses in biocompatible polymeric

sheet.

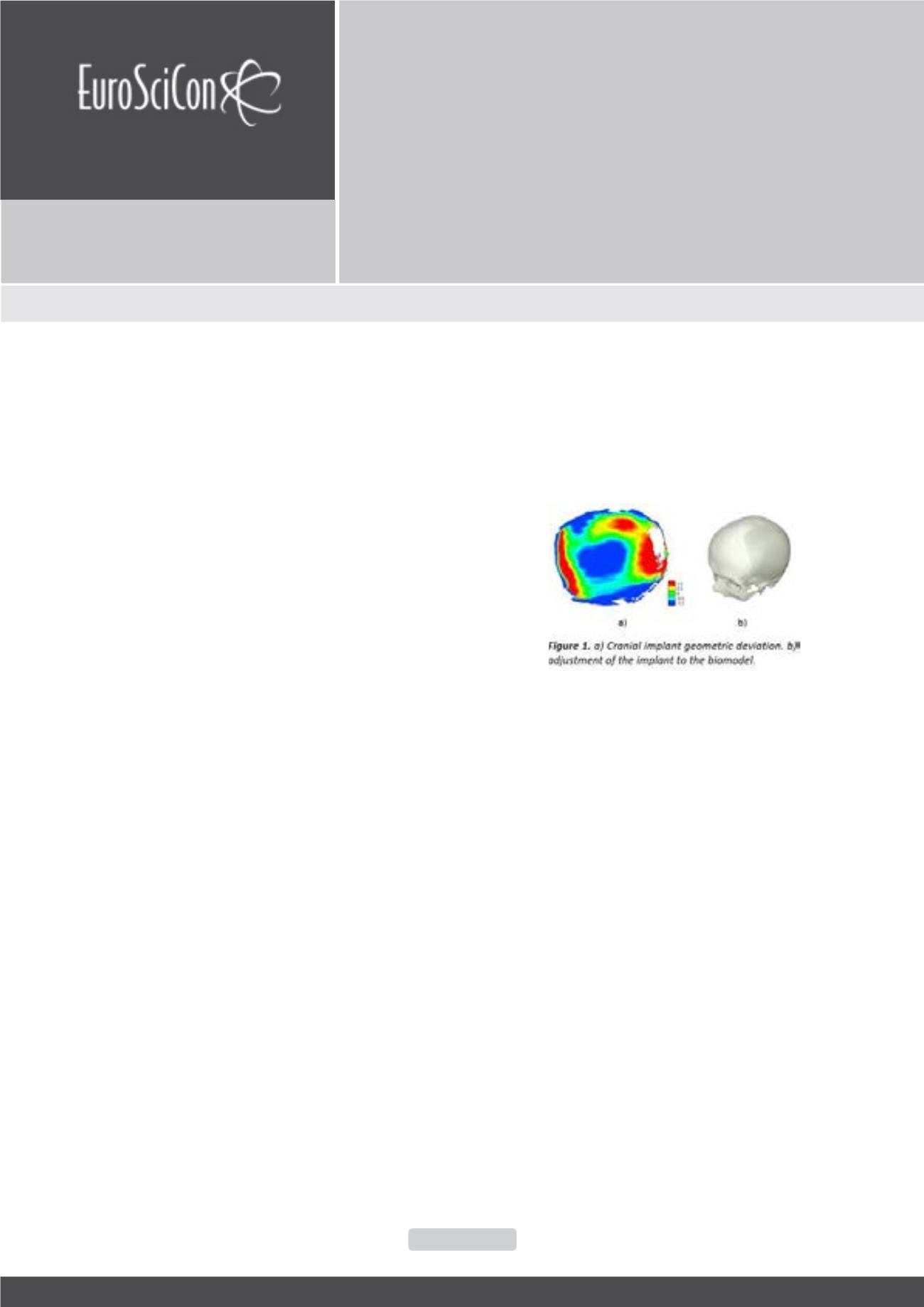

Methodology:

The cranial implant is designed based on

computerized tomographies (CT) of the patient, converting

them into a 3D model using the software InVesalius. To

generate the toolpath for the forming operation Computer

Aided Manufacturing (CAM) software is employed. Once

the cranial implant is manufactured in a Kondia CNC 3 axis

milling machine, a 3D scanning system is used to determine

the geometric deviation between the real part and the initial

design.

Findings:

The spindle speed is one of the most important

parameters that affect the results of the final part. It has been

shown that using 2000 rpm spindle speed and a negative dye

it is possible to achieve an appropriate geometric accuracy of

the prosthesis (with discrepancies below 1.5 mm) fulfilling the

standardized mechanical requirements.

Conclusions:

The use of polymeric implants in cranioplasty

is advantageously because of their lightweight, low heat

conductivity and mechanical properties similar to bone. The

results demonstrated the huge potential of manufacturing

polymeric cranial prostheses by ISF, as far as these processes

provide high formability with appropriate geometric accuracy.

Furthermore, the cost of the implant has been calculated

revealing that it is a cheap process with a low lead-time.

Recent Publications

1. SaldarriagaJF I et al. (2011) Designandmanufacturing

of a custom skull implant. American Journal of

Engineering And Applied Sciences. 4(1):169-174.

2. Bagudanch I et al. (2018) Customized cranial implant

manufactured by incremental sheet forming using a

biocompatible polymer. Rapid Prototyping Journal.

24(1).120-129.

3. Castelan J (2014) Manufacture of custom-made

cranial implants from DICOM images using 3D

printing, CAD/CAM technology and incremental sheet

forming. Brazilian Society of Biomedical Engineering.

30(3):265-273.

4. Duflou J R (2013) Manufacture of accurate titanium

cranio-facial implants with high forming angle using

single point incremental forming. Key Engineering

Materials. 549:223–230.

5. Fiorentino A et al. (2012) Rapid Prototyping Techniques

for Individualized Medical Prosthesis Manufacturing.

Proceedings Of 5th International Conference On

AdvancedManufacturingEngineeringAndTechnologies.

1:589-594. Doi: 10.1201/b11341-94.

Biography

Isabel Bagudanch is a Researcher at the Product, Process and Production

Engineering Research Group (GREP), University of Girona, Spain. Her re-

search focuses on advanced manufacturing processes such as incremen-

tal sheet forming and additive manufacturing.

isabel.bagudanch@udg.eduIncremental sheet forming for manufacturing customized

UHMWPE cranial implants

Isabel Bagudanch, Ines Ferrer

and

Maria Luisa Garcia Romeu

University of Girona, Spain

Isabel Bagudanch et al., Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-011