Polymer Congress 2018

Polymer Sciences

ISSN: 2471-9935

Page 24

June 04-05, 2018

London, UK

4

th

Edition of International Conference on

Polymer Science and

Technology

N

owadays the number of polymers produced from renewable

resources are increasing considerably. Global market

forecasts predict a fourfold increase until 2019 (7.8 million

ton/year). Polymer foams nowadays are mostly produced from

petroleum-based petrochemical materials. Foamed products,

such as packaging and insulating materials, are made by

physical, chemical and bead foaming techniques. A great

disadvantage of materials and products made from them is that

they are difficult and costly to recycle, cannot be decomposed

biologically and are a considerable load on the environment

after they lose their function. Renewable resource-based and

biodegradable polymers offer an environmentally friendly

alternative. Of all biopolymers, poly(lactic acid) (PLA) receives

the most attention nowadays. It is a thermoplastic polyester

which can be produced entirely from agricultural sources, e.g.

sugarcane, and is biodegradable by composting. PLA in itself

is rigid (Young’s modulus: ~2500 MPa), breaks easily (Charpy

impact strength: ~4 kJ/m2) and has low strain at break (~3%).

Its D-lactide content and functional additives can greatly

influence its properties. The comprehensive characterization

of its chemical foaming and the bio-foam produced this way

is a new direction of research. PLA can be used to develop

biopolymer foam products that can be a viable alternative to

single-use non-biodegradable foam products, such as food

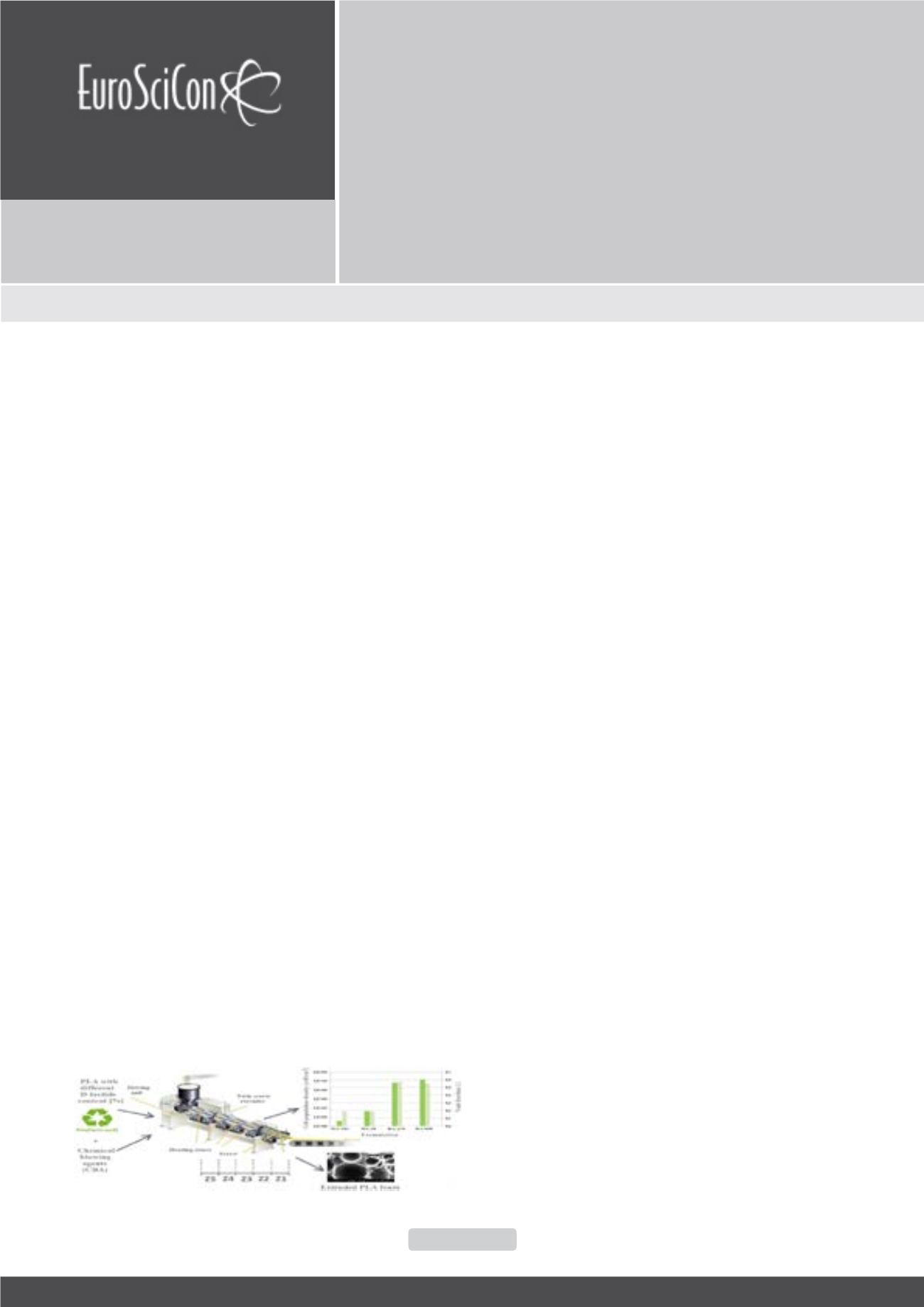

industry trays and padding foams. The lecture presents the

effects of various kinds (e.g. exothermic) of chemical foaming

agents on the morphological and mechanical properties of

PLA foam. We used PLAs with different D-lactide contents.

The PLA foams were manufactured with a twin-screw extruder.

We produced rod-shaped foam specimens. The chemical

foaming agents and the PLA foams made with them were

tested morphologically (e.g. Differential Scanning Calorimetry)

and mechanically (e.g. foam strength). The cell structure was

characterized by scanning electron microscopy.

Recent Publications

1. Nova Institute: Bio-based Building Blocks and

Polymers in the World. Michael Carus. Page 1-24.

2. Auras R et al. (2010) Poly(lactic acid). synthesis,

structures, properties, processing and application.

Wiley. ISBN:978-0-470-29366-9.

3. Julien J M et al. (2015) Chemical foaming extrusion

of poly(lactic acid) with chain-extenders: physical and

morphological characterizations. European Polymer

Journal. 67:40-49.

4. Zimmermann V G M et al. (2017) Poly(lactic acid)

foams reinforced with cellulose micro and nanofibers

and foamed by chemical blowing agents. Journal of

Cellural Plastics.

5. Göttermann S et al. (2016) Modified standard

polylactic acid (PLA) for extrusion foaming. AIP

Conference Proceedings. 1779: 060001.

Biography

Akos Kmetty is working in Research Group for Composite Science and

Technology, Hungary. His research interests are development of self-rein-

forced petroleum-based and bio-based polymer composites and the anal-

ysis of renewable resource-based polymer materials and composites. He

works as an Assistant Professor in the Department of Polymer Engineering,

Faculty of Mechanical Engineering, Budapest University of Technology and

Economics, Hungry. In 2012 he joined the MTA–BME Research Group for

Composite Science andTechnology as a Research Fellow. His work focuses

on the production and characterization of bio-polyester-based foams pro-

duced by extrusion techniques via chemical and physical blowing methods.

His research activities include the analysis of the morphological and me-

chanical properties of bio-polymer foams and he is examining the relation-

ships between the manufacturing parameters and material properties.

kmetty@pt.bme.huCharacterization of poly(lactic acid) foams produced by

extrusion with different chemical blowing agents

Akos Kmetty

1,2

and

Katalin Litauszki

1

1

Budapest University of Technology and Economics, Hungary.

2

MTA–BME Research Group for Composite Science and Technology, Hungary

Akos Kmetty et al., Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-011