ISSN : 2348-1927

Annals of Biological Sciences

Integrated Use of Flat Plate Solar Collector for the Dehydration Process of Fruit

Fahimullah Khan1*, Kang Min1,2

1College of Engineering, Nanjing Agricultural University, Nanjing, P. R. China

2Guanyun Research Institute for Modern Agricultural Equipment, Nanjing Agricultural University, Guanyun, China

Abstract

A solar collector connected to a drying chamber was constructed from available local materials (wood, metal and glass sheet) and designed for the purpose of drying of fruits, i.e., Apples and the solar collector transferred 552 Kj.m-2.h-1 heats to the drying chamber for drying fruits in the year, 2016. The fruit crop was determined by the final moisture content of <10% and was preserved for one year without deterioration. From the result, the efficiency of the solar collector was measured 30%, 25% and 23% in the months of October, November, and December respectively and from the results, it was clearly stated that the solar collector was better for drying purposes. From the experimental results, it was concluded, that increasing the solar radiation and ambient temperature, the collector efficiency increased significantly. So it was recommended to dry the fruits by FPSC drying chamber from 09:00 AM to 04:00 PM with the decreasing of drying rate of the product up to 0.011 g.(H2O).g-1(d. m).cm-2.h-1. Furthermore, it was recommended to cut the fruits into pieces and dried by the FPSC drying chamber for quick drying, good quality and taste of the dried fruits. At last, the samples were examined after 6 months; there was no attack found of insect and no spoilage result and a little difference were found in the color from lighter to darker transmittance.

Keywords

Dehydration, Efficiency, FPSC, Apple fruit, Solar energy, Solar dryer

Nomenclature

| Nomenclature | |||

|---|---|---|---|

| FPSC | Flat Plate Solar Collector | AP | Cross-Sectional of the Product (cm3) |

| SRI | Solar Radiation Intensity (kJ.m-2.min-1) | π | Content Term (3.14) |

| C.V | Chart Value | R | Radius of the Product (cm) |

| 0.88 | Content Term (Cal.cm-2.min-1) | Dm | Dry Matter (g) |

| 418 | Content Term (kJ.m-2.min-1) | Wt | Wet Weight (g) |

| Ŋ| Efficiency (%) | Dr | Drying Rate (g (H2O).g-1(d.m).cm-2.h-1) |

| Ho | Output Heat (kJ.min-1) | Dt | Time of Drying (h) |

| Hi | Input Heat (kJ.min-1) | Ao | Cross-Sectional Area of Outlet Duct (m2) |

| Ac | Area of Collector (sq. m) | Mc | Moisture Content (%) |

| Is | Incident Solar Radiation (kJ.m-2.min-1) | Wi | Initial Weight (g) |

| AF | Flow Rate (kJ.min-1) | Wf | Final Weight (g) |

| Ca | Specific Heat Capacity (kJ.kg-1.0C-1) | Da | Density of Air (kg.cm-3) |

| ΔT | Change in Temperature (ºC) | Vo | Velocity at Outlet (m.s-1) |

| FR | Flow Rate (kg.min-1) | ||

Introduction

Apple is a deciduous tree which belongs to the Rosaceae family; the botanical name is Malus domestic and most important and widely grown fruit crops all over the world. They are rich in quercetin glycosides which are antioxidative plant products belong to the flavonoids (a group of polyphenols), function as to protect from cardio and cancer diseases [1]. According to FAO, 2007, they reported that total production of apples in worldwide is 64.3 million tons and the major producers include China, United States of America, Iran, Turkey, Russian Federation and Italy, etc. [2], but in 2013 the worldwide production of apples is 80.8 million tons, while the Chinese have to account 49% of the total production [3].

Dehydration is the process of removal, moisture content level and it produced a good variety of dried fruits and vegetables [4]. Several procedures are involved in the drying process, i.e., pre-drying treatment, size selection, peeling process and color preservation, dehydrated using natural or artificial techniques [5]. In food preservation, drying is the most common method, which improves the food stability and quality of the fruits [6]. This process reduces the water content and microbiological activity of the material and also minimizes the physical and chemical changes during its storage [7]. Similarly, drying is the process which enhances their storage life of the product and minimizes during storage [8]. For dehydration, different methods were investigated as a pre-treatment-assisted freezing process. Among these methods, the air drying method has been applied to certain fruits, i.e., Pear, Kiwi, Strawberry, Melon, Pineapple and Apple [9].

The latitude and longitude of the experimental area as 34.287027°N and 118.342226°E, receiving intense solar radiation throughout the year. The total annual solar irradiance as about 7000 MJ.m-2, while the earth received 20 MJ.m-2 day-1 solar irradiances daily [10,11]. It has been evaluated that solar intensity has bright prospects of solar radiation [6]. This energy can be conserved by the use of flat plate solar collector for drying of different fruits [12] and this technique is least expensive and time-saving studied the efficiency of 35% to 45% of flat plate solar collector with the convective heat flow and noted that FPSC is the best method for the drying of fruits and vegetables [13-15].

Several years of research have shown that on-farm use of flat plate solar collector for the agricultural purpose can be an economical source of heat for different purpose, i.e., drying grain, heating purposes [16]. Open air and direct sun drying method dried the fruits and vegetables and post-harvest losses occurred is about 25% and 30%, while solar drier in the form of FPSC is the best technique to reduce these losses [17]. FPSC provides favorable conditions for drying fruits [18] and also minimized the development stage of molds, bacteria and another insect attack [19].

FPSC with the drying chamber is the techniques which to improve the drying rate and also reduce the losses in the early crop harvest and increased the storage life of the fruits and vegetables [20] and studied the drying method for the improving of solar drying method [21]. An important parameter of a solar collector is its efficiency and the air fluid flow and surrounding ambient temperature are key factors that increase the efficiency of FPSC [22]. Kaleta and Gornicki [23] studied that temperature and flow rate of the collectors increased the efficiency. Keeping in view, using of FPSC for the dehydration of fruit, i.e., Apples in the year, 2016 with the specific objectives of the study to determine the effect of temperature, humidity level and efficiency of the FPSC with the drying behavior of apples.

Methods and Materials

Preparation of fruits for drying

Apples were cut into halves pieces for 2 mm thickness and then put in hot water for blanching, and then treated with 1% citric acid solution for 3 min and the Figure 1, showed the apples before drying. The blanching prier prevents the dried products from molds and bacteria attackers and also retains the color of the products [24]. During the experiment, the digital thermometer was used for the recording of the data of dryer and collector temperature and digital hygrometer was used for the humidity level of drying chamber and outside environment. Before putting the product in the drying chamber for drying, the radius of the apples was measured with the help of inch tape for the determination of cross-sectional area of the product. After each hour of drying the drying rate and moisture loss were noted and dried up to less than 10% moisture levels [25].

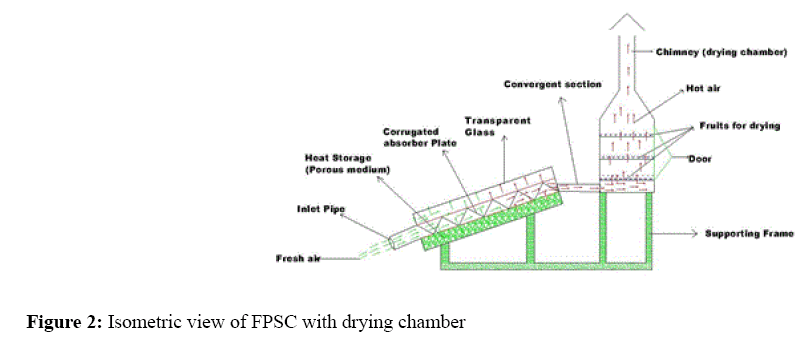

Angle of collector

The angle of the collector was tilted at the 350 with the facing of North-South axis, for receiving maximum solar radiation at the latitude (340) of the area [10]. The Figure 2, showed the isometric view of FPSC with the drying chamber.

Data collection producers

Digital Pyranometer was used for the recording data of solar radiation intensity daily basis. The incoming radiation which falls on the earth and collector was recorded in Cal.cm-2.min-1 and then convert to kJ.m-2.min-1, with the multiplication of constant term (418*0.88) [6] with the using of equation 1.

SRI = C.V × 418 × 0.88 Eq. (1)

Heat output and input ratio of the collector is to be finding the efficiency of the collector. The collector efficiency was calculated with the following equation 2 in percentage (%), studied by Kang [26].

Input “Hi” and output heat “H0” of the collector was calculated from equations 3 and 4, with the multiplication of flow rate and specific heat capacity reported by Ahmad [27]. Similarly, the flow rate (kg.min-1) was calculated with the multiplication of air velocity, density and area of the outlet duct with the using of equation 5, studied by Karimo et al. [28].

Hi=Ac × Is Eq. (3)

Ho=AF × Ca × ΔT Eq. (4)

FR=Vo × Da × Ao × 60 Eq. (5)

Data analysis of the drying fruits

The fruits were washed from the unwanted portion and then treated with 1% solution of Citric Acid and dipped for 3 min and then put in the drying chamber for drying. Before drying noted the moisture in the product was 85% and after each hour of drying the data were recorded for the determination of moisture content in the product and dried up to 10%. Equation 6, was used for the calculation of moisture content, evaluated by Hanif et al. [29].

For determining the area of fruits, inch tape was used for recording the diameter before and after each hour of drying with the using of equation 7, reported by Gul [10]. While the dry matter is the dry weight of the fruits can be calculated with the using of equation 8, evaluated by Suleyman [24].

Ap = Π × r2 Eq. (7)

Dm = Wt – (Wt × Mc) Eq. (8)

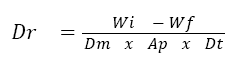

Drying rate is the evaporation of water content from the products in unit area unit time. It can be calculated from the dry matter of the product that how much moisture was lost during the drying. The equation 9 was used for the calculation of drying rate of the product in each hour, studied by studied by Eke [21].

Results and Discussion

Solar radiation intensity

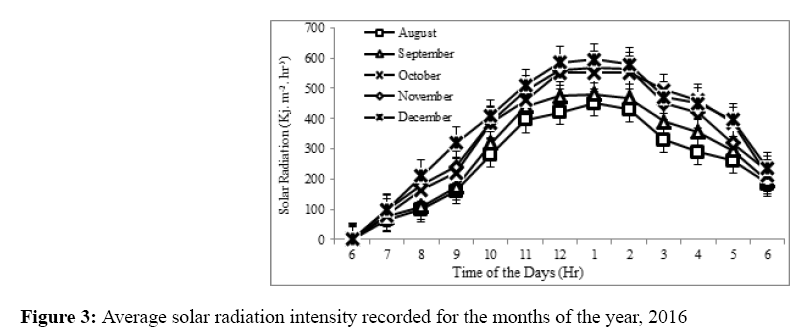

The average SRI was recorded for the months of the year, 2016 as shown in the Figure 3 with the help of digital Pyranometer (Model SM206) and showed that maximum solar radiation intensity of 450, 480, 552, 570 and 595 kJ.m-2.h-1 was noted for the months of August, September, October, November, and December at 12 Noon, respectively. The Figure 3 clearly showed that there is 45 kJ.m-2.h-1 the difference noted in solar intensity for the year because of the azimuth and zenith angles of the sun rays incident on solar collector. It was noted from the results that collector works efficiently from 9:00 AM to 4:00 PM for the drying of fruits. The standard errors bar applied on the data and showed in the figure. The error bars in line graph showed the error between the months of the year. The results are in agreement with Ahmad [27], recorded the solar radiation intensity in the months of October to December with the help of Pyranometer. It was observed that the SRI is high from 12:00 to 01:00 Noon. The results were similar to the finding of Fahim et al. [4] and Tonui et al. [12]. They reported that, for the drying of fruits and vegetables under 40-85°C range of temperature for 8 h drying with the low humidity level up to 10%.

Collector and drying chamber condition during the operation

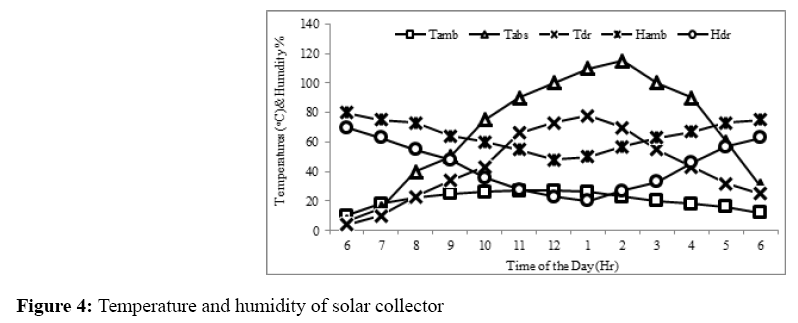

During the experiment, the temperature of the collector was found to be increasing from 09:00 AM to 12 PM Noon and the maximum temperature was noted 110°C. The temperature of the drying chamber was noted increased with the heat flow of absorber temperature through the pipe. Adnan et al. [22] reported that the range of 40 to 50°C is the suitable temperature for drying fruits. The temperature of the drying chamber at 9:00 AM was noted 40oC due to the demo sunshine and reached up to 78°C at 01:00 Noon due to clear sunshine and range of 50 to 90°C for 7 h, i.e., 09:00 AM to 04:00 PM. Eke [21] studied that for drying of fruits in the collector the range of humidity level is to be less than 40 to 50%. Figure 4, shows that in the morning time at 09:00 AM noted 48% humidity levels and starting decreased up to 20% 01:00 PM, due to the high sun radiation and remained in the range of 20 to 48% for 7 h, i.e., 09:00 AM to 04:00 PM. From the result, it was clearly shown that total of 7 h, i.e., 09:00 AM to 04:00 PM per day was available for drying of fruits in the drying chamber of the solar collector. The results are similar to the finding of Fahim [11]; they reported that the drying time of dried product was suitable from 09:00 AM to 04:00 PM during day time. The results are contradictory with the findings of Fahim et al. [6], they studied that increasing the temperature of collector the humidity of drying chamber was decreased [5,29,30] reported that the humidity of drying chamber was reduced due to the increasing the temperature of the collector.

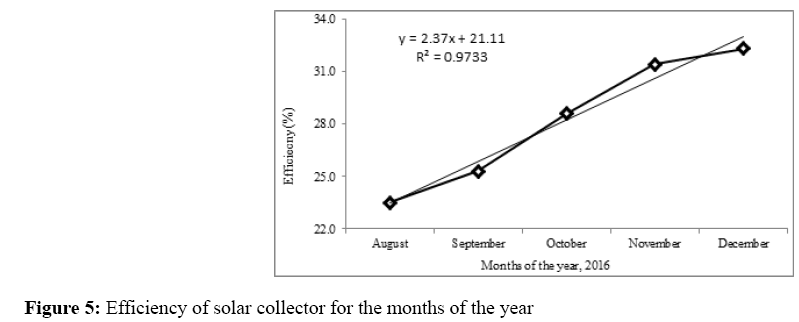

Efficiency of collector

The efficiency of solar collector was evaluated for the months of the year, 2016 with the ambient temperature of 27°C as shown in Figure 5. The efficiency of solar collector for drying was recorded up to 23.5, 25.3, 28.6, 31.4 and 32.3% for the month of August, September, October, November and December respectively. The figure showed that the maximum efficiency was noted from the months of October to December due to the sunny days, while in the rest month, the efficiency of the collector was recorded lowest due to less sunshine and low temperature.

From the Figure 5, it was clearly shown that efficiency for the month of December was higher than the other months because of highly absorbance of sun rays with the high intensity of solar irradiance. The results were similar to the finding of Fahim et al. [4], who reported that ambient temperature is directly related to the efficiency of the collector, increased ambient temperature efficiency will be increased. In the below Figure 5, the regression coefficient (R2=0.9733) value showed the nonlinear correlation relationship between the months of the year, with the using a linear model equation to find the goodness of the fit of the curves of fruits dried by the flat plate solar collector. The standard error bars are applied on the efficiency data, the bar in the graph clearly showed the error between the months of the year. Significantly increasing the efficiency of the collector with the increasing of ambient temperature was also recorded by Vestlund et al. [18]. The results are also in the agreement with the findings of Karimo et al. [28]. The results are matched with Hanif et al. [31], studied that increasing of solar radiation and surrounding temperature of the collector was increased the efficiency of the collector.

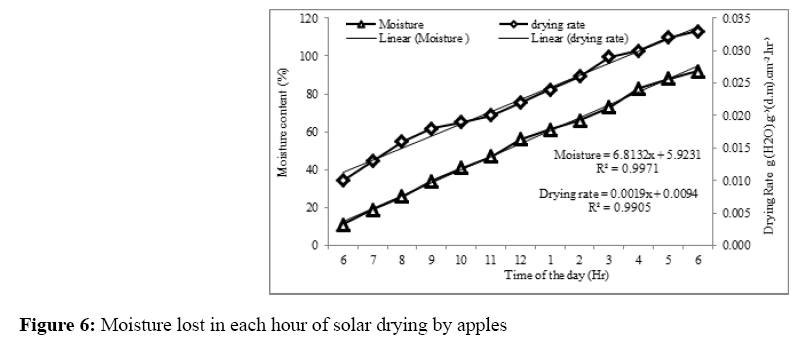

Solar drying of apples

Apple fruits were dried in FPSC drying chamber in the range of 50 to 90°C, while the humidity was noted in the range of 20 to 48% as shown in Figure 6. The products were dried in the solar collector drying chamber with the process of dehydration and moisture loss and drying rate was determined. Moisture lost in each hour of drying by an FPSC is correlated with drying time and drying rate is correlated with the change in percent moisture content to find the promising performance of the FPSC used as a solar drier for drying of fruits. Figure 6 shows the moisture lost in the apples during drying up to 50°C temperature with the humidity level of 20%. The results show that moisture was lost with the higher temperature of the drying chamber and low humidity level and it takes 2 days of the drying period. Before drying 85% moisture was noted and dried the product up to 5% moisture level with the increasing temperature of drying chamber for 2 days drying period. The nonlinear correlation values with regression coefficient (R2=0.9971) are determined using a linear model equation for the moisture lost in each hour with drying time to find the goodness of the fit of the curves of fruits dried by the flat plate solar collector. Fahim and Hanif reported that moisture content of the product was decreased with the highest temperature of the collector [11,31].

The results are similar to the finding of Zhengyong et al. [32] and Marfil et al. [33] they conducted that the increasing temperature of drying chamber of the collector was decreased the moisture content of the product and also with low humidity of the drying chamber. The standard bar deviations are applied on the moisture loss of each hour of the solar dryer that how much is deviation occur in each hour of drying time.

The drying rate of the apples was starting decreased from 0.032 g (H2O).g-1(d.m).cm-2.h-1 to 0.011 g (H2O).g-1(d.m).cm-2.h-1 with the increasing of temperature and less humidity level of the drying chamber after 13 h of the drying process. The value of the regression coefficient (R2=0.9905) is determined by using a linear model equation for the drying rate of the product in each hour with the per cent loss of moisture content in fruits, and the line showed the goodness of the fit of the curves of fruits dried by the flat plate solar collector. Karim and Hawlader [34] stated that drying rate of the product was reduced with the highest temperature of the drying chamber. The results are in agreement with Lombard et al. [35] they reported that the drying rate of the product was decreased with the decreasing of moisture content in the product. Nadia et al. [36] conducted that the drying rate of the product was decreased with low humidity and higher temperature of the drying chamber of the collector. The results are similar to the finding of Ahmet et al. [37] and Saliha et al. [38] who found that drying rate, are directly relationship with the moisture content of the product. Error bar standard deviation applied on the drying rate of the product with the moisture level, the graph showed that how much deviation present in the data of drying rate of the product. All the previous results are nearly findings with the results of Bolaji [39].

Conclusion

From the results of the experiment, it was conducted that increasing the SRI and ambient temperature of the collector was significantly increased the efficiency. Therefore, it was recommended that FPSC with the drying chamber worked efficiently as a drier for 7 h in a day from 9:00 AM to 4:00 PM in the months of October, November, and December. So it was suggested from the results that dry the fruits with the FPSC drying chamber from 9:00 AM to 4:00 PM. Further, from the results of the experiment, it was concluded that drying rate of the product was decreased with the highest temperature and less humidity level of the drying chamber of FPSC. Furthermore, the results showed that the fruits were dried in the drying chamber more easily within cutting pieces as compared to the kept as a whole, so it was recommended to cut the fruits into pieces and dried in the drying chamber of FPSC for quick drying, good quality and taste of dried fruits.

Acknowledgement

First of all thanks to all the authors, they contributed to my research work and also thanks to Prof. Kang Min to support me during research work and provide me all the facilities during research work. We extend our thanks to the China Scholarship council and the College of Engineering, Nanjing Agricultural University, Nanjing, for supporting and providing research facilities for this study.

References

- Oleksii, P., et al., Inn Food Sci Emerg Technol, 2016. 35: p. 52-57.

- Amin, H., Ali, M. and Nikbakht, A., Energy, 2016. 103: p. 679-687.

- Barbara, S., et al., Appl Ther Eng, 2014. 62: p. 455-460.

- Fahim, U., et al., Res J Appl Sci Eng Technol, 2016. 12: p. 1007-1010.

- Rastogi, N.K. and Raghavarao, K.S.M.S., Food Sci Technol, 2016. 37: p. 43-47.

- Fahim, U., et al., World J Eng, 2016. 8: p. 54.

- Janowicz, M. and Lenart, A., Food Sci Technol, 2015. 63: p. 828-836.

- Botha, G.E., et al., J Food Eng, 2016. 108: p. 304-311.

- Beate, S., et al., Food Sci Technol, 2014. 57: p. 426-433.

- Gul, N., et al., Agricultural University, 2005.

- Fahim, U., et al., Agriculture University, Peshawar, 2013.

- Tonui, K.S., et al., Res J Appl Sci Eng Technol, 2013. 7: p. 3036-3043.

- Moreno, J., et al., Inn Food Sci Emer Technol, 2016. 33: p. 381-386.

- Cuccurullo, G., et al., J Food Eng, 2012. 112: p. 319-325.

- Akwasi, A., J Solar Energy, 1997. 59: p. 121-126.

- Ashraf, M.C., et al., J. Ren Sustainable Energy Rev, 2009. 13: p. 1657-1662.

- Santos, B.M., et al., J Chemical Eng, 2005. 22: p. 6104-6632.

- Vestlund, J. Ronnelid, M. and Dalenback, J., J Solar Energy, 2009. 83: p. 896-904.

- Mahmood, Z., et al., Sarhad J Agric, 2006. 22: p. 1-5.

- Ramalho, L.A. and Mascheroni, R.H., Food Bioprod Proc, 2012. 90: p. 275-283.

- Eke, A.B., American J Agric Sci Eng Tech, 2012. 1: p. 11-26.

- Adnan, S., et al., J Experts Syst Appl, 2008. 35: p. 1533-1539.

- Kaleta, A. and Gornicki, K., Int J Food Sci Tech, 2010. 16: p. 667-687.

- Suleyman, K., J Ren Energy, 2006. 32: p. 1645-1660.

- Henderson, S.M. and Perry, R.L., Agri Proc Eng, 1976.

- Kang, M.C., et al., Int J Commun Heat Mass Transfer, 2006. 33: p. 976-984.

- Ahmed, A.G., African J Agri Res, 2011. 6: p. 343-351.

- Karimo, K.S., et al., J Solar Energy, 2004. 87: p. 49-59.

- Hanif, M., et al., Proc of the Pak Acad of Sci, 2004. 52: p. 359-363.

- Ucar, A. and Inalli, M., Int J Communications Heat Mass Transfer, 2006. 33: p. 1281-1290.

- Hanif, M., et al., Sains Malaysiana, 2016. 5: p. 489-497.

- Zhengyong, Y., Maria, J. and Oliveira, A.R., J Food Eng, 2008. 84: 430-440.

- Marfil, P.H.M., Santos, E.M. and Telis, V.R.N., Food Sci Technol, 2008. 41: p. 1642-1647.

- Karim, A.M. and Hawlader, M.N.A., J Energy Conserv Manag, 2003. 45: p. 329-344.

- Lombard, G.E., et al., J Food Eng, 2008. 85: p. 277-284.

- Nadia, D.M., et al., Food Bioprod Proc, 2012. 90: p. 433-441.

- Ahmet, K., et al., Food Bioprod Proc, 2010. 88: p. 165-173.

- Saliha, E., et al., J Food Eng, 2005. 68: p. 513-518.

- Bolaji, B.O., J Food Technol, 2005. 3: p. 595-600.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences