Effects of Ethephon Application on Olive Fruits Harvest Efficiency

Mageda A Thniebat1, Saed J Owais2, Adel H Abdel Ghani3and Saleh M Al Shdiefat 4*

1Department of Horticultural Researcher, Al-Rabba Agricultural Research Center, NARC, Al Karak, Jordan

2Department of Plant Production, Faculty of Agriculture, Mutah University, Al Karak, Jordan

3Department of Plant Production and Plant Breeding, Faculty of Agriculture, Mutah University, Al Karak, Jordan

4Department of Plant Production and Protection, Faculty of Agriculture, Jerash University, Jerash, Jordan

*Corresponding Author:

- Saleh M Al Shdiefat, Department of Plant Production and Protection, Faculty of Agriculture, Jerash University, Jerash, Jordan, E-mail: s.alshdiefat@jpu.edu.jo

Received date: June 29, 2022, Manuscript No. IPJPSAR-22-14160; Editor Assigned date: July 01, 2022, PreQC No. IPJPSAR-22-14160 (PQ); Reviewed date: July 13, 2022, QC No. IPJPSAR-22-14160; Revised date: July 22, 2022, Manuscript No. IPJPSAR-22-14160 (R); Published date: July 29, 2022, DOI: 10.36648/Ipjpsar.6.4.84

Citation: Thniebat MA, Owais SJ, Ghani AHA, Shdiefat SMA (2022) Effects of Ethephon Application on Olive Fruits Harvest Efficiency. J Plant Sci Agri Res Vol.6 No.4: 84.

Abstract

One main constraint facing olive cultivation in Jordan is the high costs of olive fruits harvest. Which constitutes about 50% of olive oil production costs, this study was carried out to evaluate the effects of two harvest dates (one week and two weeks after ethephon application), two harvesting methods (pneumatic and plastic combs) and five different ethephon concentrations (0, 1000, 2000, 3000 and 4000 ppm) on olive fruits harvesting efficiency and on some physical olive fruits related traits, harvesting fruits with pneumatic combs significantly increased the harvesting efficiency (39.6 kgh-1) as compared with plastic manual combs (29.9 Kgh-1). Harvesting efficiency was increased when harvesting was performed two weeks after ethephon application as compared with that olive fruits harvested one week after ethephon application (values were 76.7 and 63.8 kgh-1, respectively). Harvesting efficiency was gradually increased by increasing ethephon application rate from 34.8 Kgh-1 in control treatment 0 ppm ethephon) to 129.2 Kgh-1in 4000 ppm ethephon application treatment. Fruit removal force and firmness were significantly decreased by increasing ethephon application rate indicating an enhancement of fruits detachment force and acceleration of fruits ripening. In conclusion, olive fruits harvested one week after 4000 ppm ethephon application led to efficient olive fruits harvest. Pneumatic combs were much more efficient in olive fruits harvesting as compared with plastic combs.

Keywords: Ethephon; Fruit abscission; Fruit removal force; Mechanical harvesting; Olive

Introduction

Olives (Olea europaea L.) is one of the sacred trees in the mediterranean region [1]. In general, olives are drought tolerant crop that adapted to arid and semi-arid environment and grown in low rainfall areas, where supplementary irrigation implemented (international centre for agricultural research in the dry areas. 2016). One of the difficulties facing olive cultivation in Jordan is the high costs of fruit harvest, which constitutes about 50%-70% of olive oil production costs). An Olive fruit harvest is labor demanding at which traditional olive harvest by hand needs a large number of workers, but at the same time it ensures a high oil quality if harvesting process is done directly by hands. It avoids the fruits from some mechanical damage caused by the use of some mechanical tools [2]. One disadvantage of olive trees harvest by hand is that, workers may harm the trees with sticks during harvesting and this might cause damage to olive fruits and new appearing branches [3]. Manual combs are recommended to be used in Jordan. To enhance harvesting efficiency and to protect fruits and stems from mechanical damage [4].

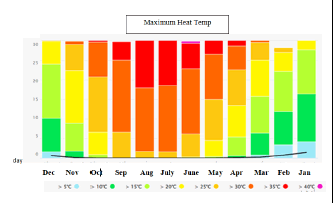

Olives harvesting period in many countries in the mediterranean basin last at least for two months from October to December. Jordanians used to start olive fruits harvesting season from the first half of November. But in 2021 harvesting season farmers observed early coloring of olive fruits, at which in mid-October, it was observed a complete black coloring of the fruits. This might be due to heat waves that Jordan has been subjected to during 2021 growing season. Therefore, an early olive fruits picking was started early and this coincide with early mills opening time. Moreover, a fruit falling on ground was a common phenomenon in 2021 harvesting season, which might be also due to early ripening because of heat waves that in consequence cause early ripening.

According to ministry of agriculture (2021) Jordan, was subjected to frequent long heat waves from May to October 2021, which has left a clear impact on olive trees in terms of production, flowering, fruit formation and maturity. It was pointed out that 2021 olive season is one of the abundantly fruitful seasons, but because of long heat waves and scarcity of rains, there was a clear impact on olive’s flowers formation and fruit set, which in consequence reflected on yield. Moreover, high temperature waves led to flowers falling and accelerated fruits coloring, which enhance early fruits picking despite of the low oil content.

Fruit mass to pedicel's strength is relatively small in olive fruits as compared with other trees of large fruits and therefore olive fruits require much more force to remove the fruits from the stalk when mechanical harvesting is applied [3]. The cost of olive harvest could be minimized by using mechanical harvest methods combined with fruits’ abscission agent such as ethephon. Ethephon can facilitate harvesting by forming an abscission layer between olive fruit and pedicle that makes olive fruits picking easier. Mechanical fruit harvesting using abscission agents was implemented in many fruit trees from decades including stone fruits, pome fruits, citrus fruits and olives. However, farmers in Jordan are used to harvest olive fruits by hand [5,6].

Ethephon (2-chloroethyelphosphonic acid) is a synthetic plant growth regulator, that releases ethelyne when it sprayed on the plant and penetrates plant tissues, at which in consequence promotes pedicel's loosening that makes fruits removal easier during harvesting [7-9]. The decomposition of ethephon to ethylene is highly dependent on the fruit growth stage and the surrounding environmental conditions including temperature and humidity [10]. One percussion when using ethephon as fruits lossening agent is not only its positive effect on fruits loosing but also its negative effect on leaves’ abscission. Even though a previous study showed a pronounced effect of ethephon on harvesting efficiency but it showed a non-significant effect of ethephon on the percentage of olive tree leaves’ abscission [11].

In the study of Ravetti and McClelland ethephon increased olive fruits yield by 20% when mechanical harvesting is used. Using ethephon as fruits loosening agent increased harvesting efficiency but it did not have significant effect on leaves drop in the subsequent years [12]. While in another study, application reduced the Fruit Removal Force (FRF) to 73% when ethephon was applied at 1250 ppm[13]. However, Touss et al. (1995) found that different ethephon doses applied 12 days before harvest had not effective role on harvest efficiency.

The use of machine such as pneumatic combs guarantee a high percentage of intact fruits that are higher than that obtained when the olives harvested by hand. Harvesting olive fruits by machines at suitable stage of maturity is largely depend on the binding force of the fruits to the pedicles, so at the proper ripening stage the binding force reduced, that the fruits will drop easily. Mechanical harvesting save the time required for harvesting, labors productivity and minimize the cost of olive production [14]. Using abscission agent to facilitate harvesting has become a common agricultural practice especially in the large scaled olive cultivated areas [15]. It promotes pedicel loosening and consequently enhances the harvesting efficiency and minimized labor demands required for olive fruits harvesting.

Harvesting of ripe olive fruits would be difficult and time consuming due to the high FRF in certain varieties. FRF is the measure used to determine the strength of pedicle attachment to the fruit and therefore affects the harvesting efficiency and the time needed to complete harvesting. Ethephon application is used as an abscission agent that makes harvesting easier by promoting pedicel loosening and makes olive fruits harvesting more efficient by reducing the time required for harvesting process in large scaled farms. Traditional olive fruits harvest by hand is the common harvest method in Jordan. But there are limited studies carried out in Jordan that focused on ethephon application on olive fruits mechanical harvesting. Therefore, the overall objective of the current study is to enhance mechanical and manual olive fruits harvest using ethephon application on “Nabali Baladi” cultivar grown in Southeastern part of Jordan.

Materials and Methods

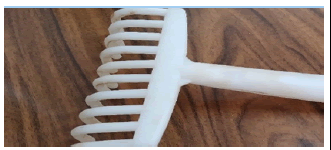

The experiment was carried out on the olive royal farm/roots project, grown at Alsmakiyah village (31° 20' 17.1 ËÂÂÂÂN 35° 49' 56.0 ËÂÂÂÂE), Northeastern to Karak district, located at 100 Km, South of Amman, Jordan (Figure 1). The experiment was consisted of five different ethephon treatments levels during olive harvesting season in 2021, two harvesting time after ethephon application (one week and two weeks) and two methods of olive fruits harvest (mechanical harvesting using pneumatic combs and manual plastic comb), in addition to the control treatment harvesting by hand(Figure 2). Ten years old olive trees of “Nabali Baladi” cultivar was used in this experiment. Trees were trained as a central leader, and spaced at 5 m × 5 m apart with a planting density of 400 trees ha-1.

Trees are usually supplementary irrigated for eight months per year, from March to October with 200-300 L/tree of about 40 L/month/tree, using drip irrigation system with daily irrigation of 4 L h-1.

Data collection

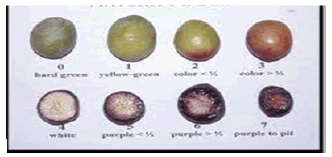

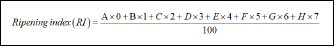

Suitable time for harvesting was determined using fruit Ripening Index (RI), which was recorded before starting ethephon treatments. It was estimated as described by Cinquanta et al. (1997), that one hundred healthy olive fruits were randomly selected from the field, and fruits were divided into halfes to show the inner pulp area color. Olive fruits were categorized into eight groups as follows: “0” with deep green skin; “1” with yellow-green peel; “2” with half of the skin turns red; Ë®3“with reddish brown leather; “4” with black skin and with white flesh; “5” with black skin and <50% purple flesh; “6” with black leather and with 50% purple flesh and “7” with black leather (Figure 3). The total number of fruits in each category recorded and the maturity coefficient estimated using the following equation to estimate the suitable time for olive fruits harvest. The RI was estimated as follows:

Where, letters A-H represents the number of fruits in each category.

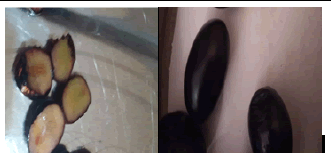

Thus, ethephon treatments were sprayed in October 9, 2021. The first harvest time was one week after ethephon application; it was in October 15, 2021. While the second harvest time, was two week after, it was in, October 21, 2021(Figure 4).

Figure 3: The standards to calculate ripening index [16].

Figure 4: Sample of olive fruits harvested from the study area in October 2021 showing early fruits coloring, black skin with white flesh.

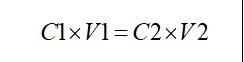

The experiment was arranged in a Randomized Completely Block Design (RCBD) with split–split plot arrangement of three replications. The experimental unit was represented with five trees. Two harvest dates (one week and two weeks after ethephon application) were used as main plots, two different harvesting methods (pneumatic combs and manual plastic comb) were used as sub-plots, and five levels of ethephon concentrations (0, 1000, 2000, 3000 and 4000 ppm) were used as sub-sub-plots(Figure 5,6). To prepare ethephon concentration we followed the following equation as mentioned by Uceda and Frias. The dilution formula was used the concentration of the starting and ending solute in ppm, the formula is:

WhereC1 is the concentration of the starting solution andV1is the volume of the starting solution. And C2is the concentration of the final solution andV2is the volume of the ending solution. Tween 20 (0.05%) was added to ethephon solution as a surfactant. “Nabali Baladi” cultivar was used to be applied by the different treatments in this experiment.

Composite samples of 2.5 Kg to 3 Kg of olive fruits were taken at harvest time from each experimental unit represented by five olive trees.

Figure 5:Pneumatic combs for olive fruits harvesting.

Figure 6: Plastic combs for olive fruits harvesting.

Fruit Removal Force (FRF) was measured at the time of harvest. It is a fruit-loosening indicator or an indicator for pedicel removal strength (in Newton) (Figure 7). It was measured for 20 randomly selected fruits per replicates by using force instruments (TPA plus). Fruit pedicel removal was measured at the maximum load and at limited points [17].

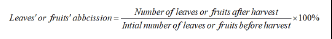

Leaves and fruits abscissions (%) were measured by counting the number of leaves and fruits before and after treatments application, as an indicator for fruits and leaves abscission. We counted fruits and leaves of three branches from each tree before ethephon application. After ethephon application, number of fallen fruits and leaves were recorded. After that, percentage of leaves and fruits abscission was estimated as follows [18].

Fruit firmness was determined by using digital force instruments (plus fruit pressure tester). Fruit pressure tester was estimated by using twenty randomly selected fruits per replicate as proposed by Small slice <2 mm from olive fruit skin was removed and then firmness recorded from the opposite sides of equatorial region of individual fruit by puncturing a 2 mm with “Taylor Probe” [19].

Harvesting efficiency

Olive fruits yield (Kg) was recorded as the total weight of fruits fallen on the ground per hour (Kgh-1), it mainly determins the quantity of fruits harvested per hour, using harvesting machines [20].

Statistical analyses

Analyses of variance was used to determine the significant differences between means for the main factors means (harvest time, harvesting methods and ethephon concentrations) in addition to their interactive effects means. Means were compared using Least Significant Difference (LSD) test at 0.01% level.

Results

The experiment was carried out to evaluate the effects of two harvest time, two mechanical harvesting tools and five different ethephon concentrations on olive fruits harvesting efficiency, fruits and leaves’ abscission. To investigate the effects of harvest time after ethephon application with five different ethephon concentrations on olive fruits physical properties, that mainly associated with olive fruits pedicle loosening and fruits ripening, which were represented by fruit removal force, fruit firmness and fruits’ and leaves’ abscission.

Effects of Time of Harvest (TH), Harvesting Method (HM) and Ethephon Concentration (EC) on harvesting efficiency and fruits and leaves’ abscission were shown in (Table 1). The interactive effects of TH × HM × EC displayed significant (P=0.01) effects on harvesting efficiency and leaves and fruits abscission (Table 1). Since the three ways interaction were significant, the results description will be focused on the best combinations were obtained when the three factors were considered together (Table1). Even though, the highest harvesting efficiency was 172.8 Kgh-1 obtained when harvesting was performed two weeks after ethephon application at 4000 ppm ethephon using pneumatic comb (Table 1). If advanced tools are not available and the farmer wants to used plastic combs which is a popular olive harvesting tool in Jordan, the highest harvesting efficiency (91.8 Kgh-1) was obtained when using 4000 ppm and by delaying harvest time two weeks after ethephon application.

The highest leaves abscission (9.7%) was obtained when harvesting was performed two weeks after ethephon application at 4000 ppm and by using pneumatic comb, while the leaves abscission value was (5.6%) when plastic comb was used with 4000 ppm ethephon two week after ethephon application (Table 1). The maximum fruits abscission (98.1%) was obtained when olive fruits were harvested two week after ethephon concentration at 4000 ppm using pneumatic comb, while the fruits abscission value was (95.9 %) when plastic comb was used and harvesting performed two week after 4000 ppm ethephon application (Table 2). As a general trend, the fruits abscission values were close to each when high doses of ethephon were used (range from 95% to 99%).

| Ethephone concentration | |||||||||||

| Harvesting Efficiency | 0 | 1000 | 2000 | 3000 | 4000 | ||||||

| Date of harvest | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | mean |

| Week 1 | 39.62 | 29.95 | 39.68 | 30.13 | 62.74 | 35.97 | 92.24 | 55.4 | 168.19 | 83.97 | 63.8b |

| Week2 | 39.67 | 29.9 | 46.09 | 32.33 | 87.17 | 37.93 | 166.89 | 62.87 | 172.77 | 91.77 | 76.7a |

| Mean | 39.6 | 29.9 | 42.88 | 31.1 | 74.95 | 36.95 | 129.56 | 56.63 | 170.48 | 87.87 | |

| mean | 34.78e | 36.99d | 55.95c | 93.09b | 129.17a | ||||||

| Leaf abscission % | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | mean |

| Week 1 | 9.24 | 5.18 | 9.36 | 5.25 | 9.42 | 5.29 | 9.53 | 5.35 | 9.64 | 5.42 | 7.37b |

| Week 2 | 9.34 | 5.23 | 9.41 | 5.27 | 9.52 | 5.31 | 9.55 | 5.39 | 9.68 | 5.59 | 7.43a |

| Mean | 9.29 | 5.2 | 9.38 | 5.26 | 9.47 | 5.3 | 9.54 | 5.37 | 9.66 | 5.51 | |

| Mean | 7.24e | 7.32d | 7.39c | 7.46b | 7.59a | ||||||

| Fruit abscission % | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | Pneumatic combs | Plastic combs | mean |

| Week 1 | 36.44 | 27.46 | 49.09 | 39.05 | 58.12 | 43.44 | 79.54 | 62.32 | 95.11 | 88.31 | 57.9b |

| Week 2 | 36.71 | 28.61 | 51.56 | 39.91 | 61.23 | 46.43 | 82.17 | 65.31 | 98.12 | 95.9 | 60.6a |

| Mean | 36.58 | 28.03 | 50.33 | 39.48 | 59.68 | 44.93 | 80.86 | 63.82 | 96.61 | 92.61 | |

| Mean | 32.31e | 44.91d | 52.31c | 72.34b | 94.61a | ||||||

| *LSD: To compare means at the same or different levels of the subplot | |||||||||||

Table 1: The interactive effects of harvesting time, harvesting methods and ethephon concentration on harvesting efficiency (Kghr-1), leaves and fruits abscission (%).

The interactive effects of harvest time and ethephon concentration on Ripening Index (RI), FRF and Firmness. The interactive effects of the time of harvest and ethephon concentration displayed significant (P=0.01) effects on RI, FRF and firmness (Table 2). The highest RI obtained was 4.24 and 4.64 when olive fruits harvested one week and two weeks; respectively after 4000 ppm ethephon application. The interactive effect of ethephon concentration and harvesting time was significant on olive fruits removal force and firmness. The FRF was reduced from (6.27 N to 4.43 N) and the firmness reduced from (3.25 N to 2.87 N) when ethephon was applied at 4000 ppm one week and two weeks after ethephon application rate; respectively (Table 2). The results indicate that high ethephon application rate (4000 ppm) significantly reduced the FRF, while the time of harvest had very slight effects on fruit loosening (i.e. FRF).

The interactive effect of ethephon concentration and harvesting time was significant on fruit firmness. The highest reduction in firmness was obtained when ethephon was applied two weeks after 4000 ppm (Table 2). Firmness was significantly reduced from 3.27 in the control treatment to 2.03 two weeks after 4000 ppm ethephon application. Firmness was also significantly reduced from 3.49 in the control to 3.00 one week after 4000 ppm ethephon application (Table 2). Generally, if firmness is considered as an indicator for olive harvesting and ripening, then the olive fruits harvested one week and two weeks at 4000 ppm ethephon. So the firmness was still within the standard range of olive fruit firmness which should not decrease below 1.7.

| Parameters | ||||

|---|---|---|---|---|

| Ripening index (0-7) | Date of harvest | |||

| Ethephon concentration ppm sub plot treatments | One week | 2nd week | Mean | |

| 0 | 4.01e | 4.28e | 4.15e | |

| 1000 | 4.16d | 4.34d | 4.25d | |

| 2000 | 4.23c | 4.69c | 4.46c | |

| 3000 | 4.30b | 4.91b | 4.61b | |

| 4000 | 4.41a | 4.96a | 4.69a | |

| Mean | 4.24 | 4.64 | ||

| Firmness Newton\mm | ||||

| 0 | 3.49a | 3.27a | 3.38a | |

| 1000 | 3.46b | 3.23b | 3.35b | |

| 2000 | 3.19c | 3.03c | 3.11c | |

| 3000 | 3.13d | 2.80d | 2.97d | |

| 4000 | 3.00e | 2.03e | 2.52e | |

| Mean | 3.25 | 2.87 | 3.07 | |

| Fruit removal force (Newton) | ||||

| 0 | 7.13a | 6.88a | 7.01a | |

| 1000 | 7.04b | 6.46b | 6.75b | |

| 2000 | 6.1c | 4.15c | 5.13c | |

| 3000 | 4.02d | 3.21d | 3.62d | |

| 4000 | 2.09e | 1.49e | 1.79e | |

| Mean | 6.27 | 4.43 | ||

| *LSD to compare two subplot means (averaged over all sub-subplot treatments) at the same levels of the whole plot. **LSD to compare two whole plot means (averaged over all sub-subplot treatments) at the same or different levels of the subplot. | ||||

Table 2: Interactive effects of date of harvest and ethephon concentration on ripening, firmness and fruit removal force.

Discussion

There is a scarcity of published reports on the effects of ethephon application rate on olive fruits harvesting in Jordan. Therefore, the current experiment was carried out to evaluate the effects of five ethephon concentration, two harvest time and two mechanical harvesting tools on olive fruits harvesting efficiency throughout 2021 cropping season. Olive fruits physical properties were also recorded including fruits removal force, fruit firmness, fruits’ and leaves’ abscission. The experiment was implemented using “Nabali Baladi” cultivar. In this experiment, the research questions were successfully answered. The harvesting efficiency was enhanced by using both mechanical and manual harvesting tools, where higher ethephon concentrations led to efficient olive fruits harvest. Pneumatic combs were much more efficient in olive fruits harvesting as compared with plastic combs harvesting tool.

In 2021 cropping season, olive crop in Jordan was exposed to frequent hot waves, which accelerated olive fruits ripening and coloring. Therefore, it is essential to use RI rather than fruits coloring to determine the fruits ripening stage. According the Ministry of Agriculture of Jordan (MOA), (2021), high temperature throughout the growing season accelerated olive fruits coloring and in consequence fruits harvest started earlier in 2021 as compared with the previous seasons, in the first half of October. Accumulated rainfalls throughout 2021 season (120 mm) were extremely low (MOA, 2021). Eventhough supplementary irrigation was used in the experimental site, while the olive trees still exposed to partial water deficit during 2021 cropping season.

Generally, olive fruits growth and development are influenced by genotype, environmental conditions and agricultural practices throughout the growing season [21]. Rainfall scarcity could affect fruit ripening stage and ultimately the quality [22-26] Ethylene accumulation under stresses (high temperature and low rainfall) could enhance senescence hormones such as ethylene, which accelerating olive fruits ripening and coloring. “Nabali Baladi” cultivar is a widely cultivated cultivar in Jordan. It shows high adaptability to prevailing environmental conditions and had been cultivated in Jordan for decades [27]. It is characterized by high yield and high oil quality. It is also displaying a variation in ripening according to the variation in prevailing environmental conditions that ultimately influences the accumulation of phenolic compounds in the olive oil. Fruits ripening and coloring are highly dependent on prevailing conditions during the growing season and on the time of olive fruits coloring [28].

Pneumatic combs were more efficient in harvesting olive fruits as compared with plastic combs especially when a high ethephon dose (4000 ppm) was applied. Harvesting efficacy was increased with increasing ethephon application rate and consequently affected the efficiency of harvesting tools. High harvesting efficiencies obtained at 4000 ppm ethephon rate is attributed to lower FRF that in consequence increased fruits’ abscission. It was significantly higher when pneumatic combs were used as compared to plastic combs (39.6 and 29.9 kgh-1; respectively) (Table 1). In an experiment, using mechanical harvesting and 2000 ppm-3000 ppm ethephon application removed 60% of olive fruits [29]. The cost of olive harvest using different harvesting machines with ethephon application was minimized, indicating that ethephon application not only enhances harvest efficiency but also minimizes the olive fruits harvesting cost.

Effects of different ethephon concentrations were tested on harvest efficiency, RI, FRF, and fruits’ abscission. In this study, increasing ethephon application rate, significantly increased the RI; however, RI is still within the acceptable range (4-4.5) at 4000 ppm ethephon application rate. Also, leaves’ abscission was slightly affected by ethephon application rate. It is worth to mention that effect of delaying harvest was much more effective on fruits ripening when compared with early ethephon application. Ethephon as ethylene releasing compound was used as fruit thinning, but excessive use of ethephon application can cause significant leaves losses [30]. Ethephon is known as the compound of inducing fruits’ abscission agent [31-35], therefore, it is wiser to know the effective concentration rate of ethephon that facilitate harvesting and avoiding olive fruits over ripening and excessive leaves loss. From these perspectives, the current study showed that the best combination treatment is using 4000 ppm ethephon and harvesting olive fruits one week after ethephon application to ensure high harvest efficiency.

And in order to minimize the cost of olive production, it is necessary to use mechanical harvesting tools combined with a suitable ethephon concentration rate [36]. Ethephon was used as loosening–agent, to make olive fruits easy to pick by mechanical harvesting. This has been documented in different fruit types [37, 38] including olive. Excessive ethephon concentration rate can cause excessive leaves’ loss, which expose olive tree to knot bacteria (Pseudomonas syringae pv. savastanoi) and considerable yield losses in the following seasons can be happened.

Harvesting date and its relation with olive fruits harvesting efficiency and related olive fruits parameters. Two harvest dates after ethephon application (one week and two weeks) were experimentally tested. Delaying olive fruits harvest two weeks after 4000 ppm ethephon application led to accelerated olive fruits ripening and consequently led to a negative impact on olive oil quality. Manual olive fruits harvesting expends 50% to 80% of the total olive oil production cost [39, 40]. The fruit RI was significantly increased in “Nabali Baladi” cultivar with the progress of fruit maturation process and after exposing olive fruit to high ethephon concentration (4000 ppm). Photosynthetic activity in olive fruits is reduced with the progress of fruit ripening, which in consequence reduce chlorophyll and carotenoid contents of olive fruits. At late stages of fruit maturation olive fruits become violet or purple due to the accumulation of anthocyanin. Olive fruit color changes are also reflected on fruit firmness and both chemical and sensory olive oil quality parameters. The fruit firmness in “Nabali Baladi” cultivar significantly decreased when olive fruits were collected two weeks after ethephon application as compared with fruits harvest one week after ethephon application.

Ethephon application one week and two weeks after ethephon application might lead to higher ethylene accumulation in olive fruits. Consequently, olive fruit ripening is promoted as reflected in higher RI. After ethephon spraying, higher levels of endogenous ethylene accumulation is occurred at late stages of olive fruit ripening, 175-190 days after full bloom and pre-harvest application of ethephon accelerates ripening of a non-climacteric olive fruit. Reported that, during olive fruit ripening rapid changes occurred in the fruit firmness from hard to soft. Changes in chemical and biochemical contents of ripened olive fruits also occurred which are genotype, climate and prevailing growing conditions dependent. Chemical and biochemical changes in the texture reduced flesh fruits firmness with the progress of fruit maturation. Olive pulp firmness decreases due to losing in olive fruits pulp cell wall. During maturation, loosing fruit firmness is mainly due to methyl esterification of pectic polysaccharides in olive fruit pulp cells and due to the loosening of complexation between galacturonic acid and Ca.

FRF was reduced by delaying fruit harvest two weeks after 4000 ppm ethephon application. It is linearly correlated with fruit development stage and decreases with maturity. Reduction in FRF in this experiment is related to the endogenous ethylene level, which increases as the fruit ripens. The genotypic differences are also existed that increase FRF between genotypes. The stalk thickness in olive fruit is genotype dependent, which becomes looser with maturity.

The FRF is decreased with increasing ethephon application rate (Table 2). Ethephon releases ethylene as it penetrates plant tissue, making the pedicle weaker by reducing FRF. Overlapping way peltate trichomes can be penetrated by high ethephon application rate. FRF significantly reduced when harvesting is delayed from one week to two-week after ethephon spraying. RI is significantly increased due to ethylene accumulation in plant tissues. The RI of “Nabali Baladi” cultivar was significantly increased by ethephon application as compared to the control treatment (0 ppm ethephon).

It seems that ethylene produced one week and two weeks after ethephon application was effective in increasing the RI, fruits’ abscission and it was also effective in reducing the FRF. In this experiment, ethylene slightly increased leaves’ abscission, which in line with many previous studies. The growth stage and environmental conditions including temperature and relative humidity affect the extent of ethylene penetration into the plant cells and the amount of ethylene released by increased ethephon decomposition. El-Tamzini et al. reported 73% reduction in the FRF when olive trees were treated with 2250 mg L-1 ethephon.

Fruit abscission was significantly increased with increasing ethephon application rate. The effect of abscission agents had been reported to reduce fruit-detachment force and consequently increasing the harvest efficiency. The internal ethylene production should be effective as the external ethephon application increases. Ethephon induces fruit abscission by accumulating more ethylene in the pedicel-fruit basin and leaf surface, which completely penetrates plant tissue.

Conclusion

From this experiment, we concluded that the highest harvesting efficiency was obtained when olive fruits were harvested one week after 4000 ppm ethephon application. While pneumatic combs displayed higher harvesting efficiency as compared with plastic combs when olive harvesting was performed one week after 4000 ppm ethephon application. Fruit Removal Force (FRF) was gradually decreased by increasing ethephon application rate indicating that ethephon plays a significant role in fruit detachment by promoting pedicel loosening (fruits’ abscission), which in turn enhances the harvesting efficiency and minimized labor demands required for olive fruits harvesting. Moreover, fruit firmness reduced and fruit RI enhanced by increasing ethephon application rate.

Recommendations

From this study, we ensure mechanical harvesting using pneumatic combs one week after ethephone application at 4000 ppm.

More researches needed, to study the effect of different ethephone application concentration on the other olive cultivars cultivated in southern part of Jordan.

Refernces

- Abeles FB, Craker LE, Leather GR (1971) Abscission: The phytogerontological effects of ethylene. Plant Physiol 47: 7-9.

[Crossref], [Google Scholar], [Indexed]

- Ahmad R, Ayoub S (2014) Acomparative study of hand-held harvesting machine with traditional methods used for olive harvesting in Jordan, NC Research gate.

- Anastasopoulos E, Kalogeropoulos N, Kaliora AC,Kountouri A, Andrikopoulos NK (2011) The influence of ripening and crop year on quality indices, polyphenols ,terpenic acid squalene, fatty acid profile, and sterols in virgin olive oil (Koroneiki cv.) produced by organic versus non-organic cultivation method. J Food Sci Tech 46: 170-178.

[Crossref], [Google Scholar], [Indexed]

- Banno K, Martin GC, Carlson RM (1993) The role of phosphorus as an bscission-inducing agent for olive leaves and fruit. J Amer Soc Hort Sci 118: 599-604.

[Crossref], [Google Scholar], [Indexed]

- Barone E, Gullo G, Zappia R, Inglese P (1994) Effect of crop load on fruit ripening and olive oil (Olea europaea L.) quality. J Hort Sci 69: 67-73.

[Crossref], [Google Scholar], [Indexed]

- Barranco D, Toro CC de, Oria M, Rapoport HF (2000) Monopotassium phosphate (PO4H2K) for olive fruit abscission. Acta Hortic 586: 263-266.

[Crossref], [Google Scholar], [Indexed]

- Barranco D, Arquero O, Navarro C, Rapoport HF (2004) Monopotassium phosphate for olive fruit abscission. J Hort Sci 39: 1313–1314.

[Crossref], [Google Scholar], [Indexed]

- Beaudry RM,Kays SJ (1987) Effects of physical and environmental factors on the release ofethylene from (2- chloroethyl) phosphonic acid and (2-chloroethyl)-methyl-bis- (phenylmethoxy) silane. J Amer Soc Hort Sci 112: 352-359.

[Crossref], [Google Scholar], [Indexed]

- Beltran G, Río CD, Sánchez S, Martínez L (2000) Seasonal changes in olive fruit characteristics and oil accumulation during ripening process. J Sci Food Agri 84: 1783-1790.

[Crossref], [Google Scholar], [Indexed]

- Ben-Tal Y (1992) Quantification of ethephon requirements for abscission in olive fruits. Plant Growth Reg. 11: 397-403.

[Crossref], [Google Scholar], [Indexed]

- Ben-Tal Y, Lavee S (1976) Increasing the effectiveness of ethephon for olive harvesting. J Hort Sci 11: 489-490.

[Crossref], [Google Scholar]

- Burns JK, Buker RS,Roka FM (2005) Mechanical harvesting capacity in sweet orange is increased with an abscission agent. Hort Tech 15: 758-765.

[Crossref], [Google Scholar] , [Indexed]

- Chaves AL, Mello-Farias PCD (2006) Ethylene and fruit ripening: From illumination gas to the control of gene expression, more than a century of discoveries. Plant Mol Biol 29: 508-515.

[Crossref], [Google Scholar] , [Indexed]

- Dung CD (2013) Factors controlling vase life of waxflowers (Chamelaucium Desf. Varieties and Hybrids). Curtin University of Technology, Western Australia.

- Ferguson L, Rosa UA, Castro-Garcia S, Lee SM, Guinard JX et al.(2010) Mechanical harvest of California table and oil olives. Adv Hort Sci 24: 53–63.

[Crossref], [Google Scholar] , [Indexed]

- Ferreira JA, Mafra I, Soares MR,Evtuguin DV,Coimbra MA (2006) Dimeric calcium complexes of arabin-rich pectic polysaccharides from Olea europaea L. cell walls. Carb Polym 65: 535-543.

[Crossref], [Google Scholar] , [Indexed]

- Flore JA, Bukovac MJ (1982) Factors influencing absorption of 14C (2-chloroethyl) phosphonic acid by leaves of cherry. J Amer Soc Hort Sci 107: 965-968.

[Crossref], [Google Scholar] , [Indexed]

- Gutierrez F, Varona I, Albi MA (2000) Relation of acidity and sensory quality with sterol content of olive oil from stored fruit. J Agric Food Chem 48: 1106-1110.

[Crossref], [Google Scholar] , [Indexed]

- Hartmann HT, Tombesi A, Whisler J (1970) Promotion of ethylene evolution and fruit abscission in the olive by 2- chloroethanephosphonic acid and cycloheximide. J Amer Soc Hort Sci 95: 635-640.

[Crossref], [Google Scholar] , [Indexed]

- Henry EW, Jensen TE (1973) Peroxidases in tobacco abscission zone tissue. 1. Fine structural localization in cell walls during ethylene induced abscission. J Cell Sci 13: 591-601.

[Crossref], [Google Scholar] , [Indexed]

- Jackson MB,Osborne DJ (1972) Abscisic acid, auxin and ethylene in explants abscission. J Exp Bot 23: 849-862.

[Crossref], [Google Scholar] , [Indexed]

- Jimenez A, Rodriguez RI, Fernadez-Caro R, Guillen R, Fernadez-Bolanos J et al.(2001) Olive fruit cell wall: Degradation of pectic polysaccharides during ripening. J Agric Food Chem 49: 409-415.

[Crossref], [Google Scholar] , [Indexed]

- Kadman A, Ben-Tal Y (1983) Inducing macadamia nut fruit drop with ethephon.J Hort Sci 18: 20-242.

[Crossref], [Google Scholar]

- Lavee S, Haskal A (1975) Studies with ethephon for facilitating olive harvest. Sci Hort 3: 163-171.

[Crossref], [Google Scholar] , [Indexed]

- Lavee S, Avidan B, Ben-Tal Y (1982) >Effect of fruit size and yield on the fruit removal force within and between cultivars. Sci Hort 286: 441-451.

[Crossref], [Google Scholar] , [Indexed]

- Lavee S, Barshi G, Haskal (1973) Natural fruit drop and induced abscission to facilitate mechanical harvesting of Manzaillla and Souri olives. Sci Hort 1: 63-75.

[Crossref], [Google Scholar] , [Indexed]

- Martin GC, Lavee S, Sibbett GS (1981) Chemical loosening agents to assist mechanical harvest of olive. J Amer Soc Hort Sci 106: 325-330.

[Crossref], [Google Scholar]

- Metzidakis I (1999) Field studies for mechanical harvesting by using chemicals for the loosening ofolive pedicel on cv. Koroneiki. Acta Hortic 474: 112-117.

[Crossref], [Google Scholar] , [Indexed]

- Nanos GD, Thomai T, Sfakiotakis EM, Fitsio N (1999) Maturity indices for green olives destined to be processed as 'Spanish-style' olives. Acta Hort 474: 521-524.

[Crossref], [Google Scholar] , [Indexed]

- Olein WC, Bukovac MJ (1978) The effect of temperature on rate of ethylene evolution from ethephon and from ethephon-treated leaves of sour cherry. J Amer Soc Hort Sci 103:199-202.

[Crossref], [Google Scholar]

- Olien WC, Bukovac MJ (1982) Ethylene generation, temperature responses and relative biological activities of several compounds with potential for promoting abscission of sour cherry fruit. J Amer Soc Hort Sci 107: 1085-1089.

[Crossref], [Google Scholar] , [Indexed]

- Polito VS, Lavee S (1980) Anatomical and histochemical aspects of ethephon-induced leaf abscission in olive (Olea europaea L). Bot Gaz 141: 413-417.

[Crossref], [Google Scholar] , [Indexed]

- Reed NR, Hartmann HT (1976) Histochemical and ultrastructural studies of fruit abscission in olive after treatment with 2-chlorethyl-tris-(2-methoxyethoxy)-silane. J Amer Soc Hort Sci 101: 633-637.

[Crossref], [Google Scholar] , [Indexed]

- Rotondi A, Bendini A, Cerretani L, Mari M, Lercker G et al (2004) Effect of olive ripening degree on the oxidative stability and organoleptic properties of cv.Nostrana di Brisighella extra virgin olive oil. J Agri Food Chem 52: 3649-3654.

[Crossref], [Google Scholar] , [Indexed]

- Salvador M, Aranda F, Fregapane G (2001) Influence of fruit ripening on Cornicabra virgin olive oil quality. A study of four successive crop seasons. Food Chem 73: 45-53.

[Crossref], [Google Scholar] , [Indexed]

- Tharanathan RN, Yashoda HM, Praba TN (2006) Mango (Mangifera indica L.), the king of fruits - An overview. Food Rev Int 22: 95-123.

[Crossref], [Google Scholar] , [Indexed]

- Tombesi A (1994) Olive fruit growth and metabolism. Acta Hortic 356: 225-232.

[Crossref], [Google Scholar] , [Indexed]

- Touss J, Lloveras J, Romero A (1995) Effect of ethephon spray treatments on mechanical harvesting and oil composition of Arbequina olives. J Amer Soc Hort Sci 120: 558-561.

[Crossref], [Google Scholar]

- Weis KG, Webster BD, Goren R, Martin GC (1991) Inflorescence abscission in olive: Anatomy and histo- chemistry in response to ethylene and ethephon. Bot Gaz 152: 51-58.

[Crossref], [Google Scholar] , [Indexed]

- Weis KG, Goren R, Martin GC, Webster BD (1988) Leaf and inflorescence abscission in olive. I. Regulation by ethylene and ethephon. Bot Gaz 149: 391-397.

[Crossref], [Google Scholar] , [Indexed]

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences