Polymer Congress 2018

Polymer Sciences

ISSN: 2471-9935

Page 60

June 04-05, 2018

London, UK

4

th

Edition of International Conference on

Polymer Science and

Technology

Dae Su Kim et al., Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-012

Characterization of composite films prepared by in-situ

polymerization of styrene/butyl acrylate in nanoporous

cellulose gels

Dae Su Kim

and

Jyoti Sankar Borah

Chungbuk National University, Republic of South Korea

P

olymer/cellulose composites have attracted lots of interest

because they can have high strength to weight ratios, low

thermal expansion coefficients, cost competitiveness, and

eco-friendliness. To prepare a high performance polymer/

cellulose composite the chemical modification of cellulose

would be essentially carried out via the hydroxyl groups of

cellulose to make the hydrophilic cellulose more compatible

to the generally hydrophobic polymer. However, manufacturing

a high performance polymer/cellulose composite is still a

challenge because of the poor dispersion and distribution

of cellulose fillers in a hydrophobic polymer matrix and poor

interfacial adhesion between cellulose and the polymer

matrix. Most of the published studies on polymer/cellulose

composites used natural cellulose fillers (fibers or particles)

with native molecular structure. However, nanoporous

cellulose gels (NCGs) with regenerated molecular structure

can be prepared by dissolution and coagulation of native

cellulose molecules and used as fillers to reinforce polymers.

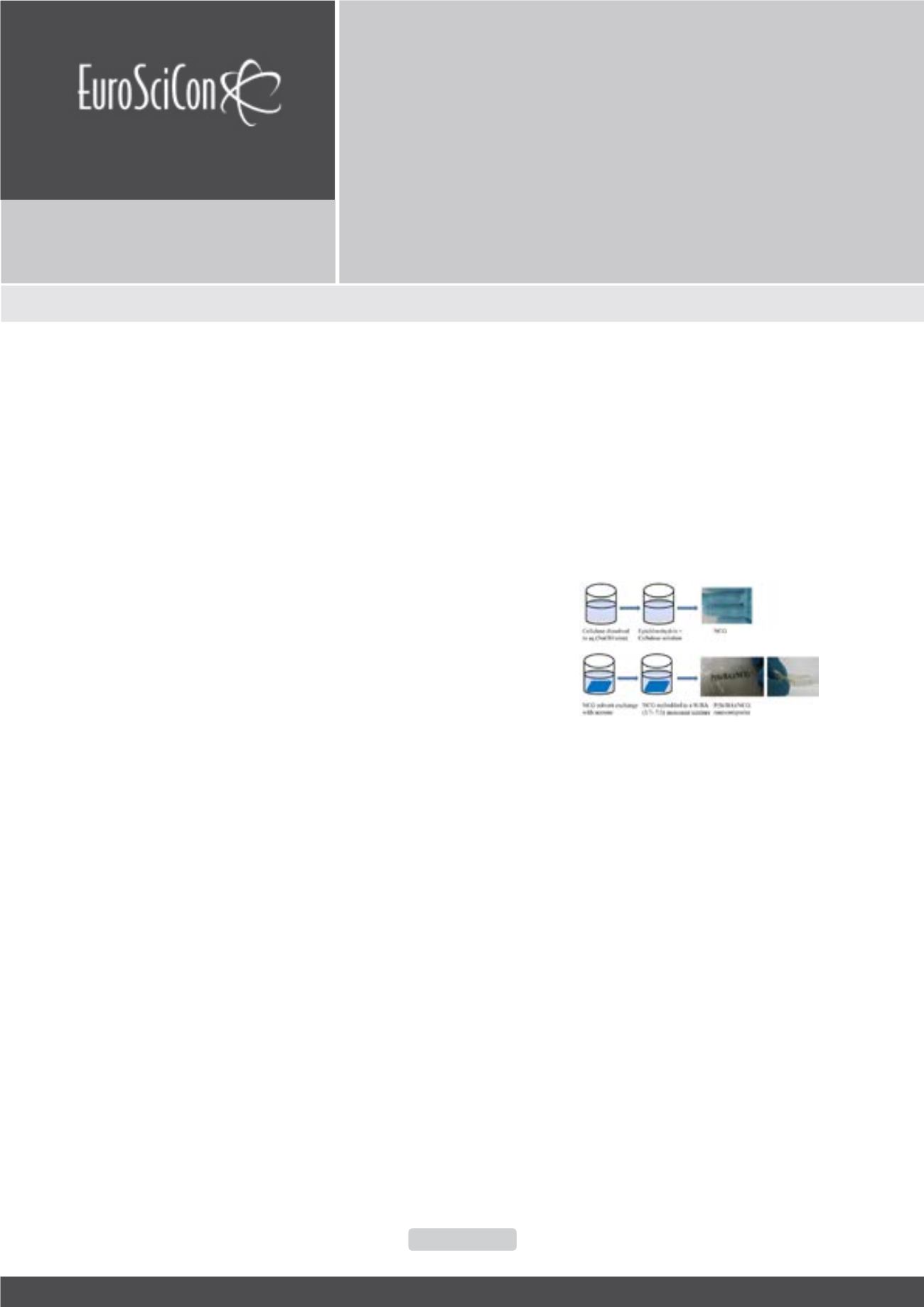

Therefore, in this study, film-shape NCGs were prepared first

using microcrystalline cellulose powder via (1) dissolution

of cellulose chains in an aqueous alkali hydroxide/urea

solution and (2) crosslinking of cellulose chains by adding

epichlorohydrin to (1). Then, poly(styrene-co-butyl acrylate)/

NCG composite films were prepared by in-situ polymerization

of each styrene/butyl acrylate (St/BA=3/7~7/3) monomer

mixture with benzoyl peroxide 1% as an initiator in the NCGs. A

monomer mixture was imbedded in the cavities of an NCG first

then in-situ polymerized at 50°C for 12 h. The NCG contents in

the composite films were controlled from 16 vol.% to 44 vol.%

by controlling the dewatering level of the pristine nanoporous

cellulose hydrogel using different compression forces. The

composite film prepared with St/BA=3/7 monomer mixture

was highly transparent (~82%) in the visible region and showed

excellent tensile and dynamic mechanical properties.

Recent Publications

1. Jang S Y and Kim D S (2016) Physical properties of

polypropylene composites with hydrophobized cellulose

powder by soybean oil. J Appl. Polym. Sci. 133(6):42929.

2. Xu C et al. (2017) Polylactide/cellulose nanocrystal

composites: a. comparative study on cold and melt

crystallization. Cellulose. 24(5):2163-2175.

3. Tanaka S, Iwata T and Iji M (2016) Solvent effects on

heterogeneous synthesis of cardanol- bonded cellulose

thermoplastics. Polymer. 99:307-314.

4. Cai J, Kimura S, Wada M and Kuga S (2009)

Nanoporous cellulose as metal nanoparticles support.

Biomacromolecules. 10(1):87-94.

5. Chang C and Zhang L (2011) Cellulose-based hydrogels:

present status and application prospects. Carbohydrate

Polymers. 84(1):40-53.

Figure 1:

Preparation of NCG and a poly(styrene-co-butyl acrylate)/NCG composite.