ISSN : 0976-8505

Der Chemica Sinica

Effect of Rod Crystal Dimensions on Thermal Stress in Nd: YLF Laser with 20W End-Diode Pumped

Khalid A Yahya, Oday A Hussein and Ola H Mustafa

Department of Physics, College of Science, Al-Nahrain University, Baghdad, Iraq

Abstract

Theoretical results are reported on thermal stress effects along the π 1047 nm and σ 1053 nm polarizations in an a cut Nd: YLF rod crystal by using 20 W diode-end-pumped. The effects of rod crystal length and radius on the distribution of radial temperature and thermal stress are studied. The result from this study has shown that the temperature in a center of rod is decreased when the length of crystal increases. The center of the rod is under compression, while the surface of the rod is under tension. Furthermore, the effect of thermal stress for π polarized 1047 nm is stronger than σ polarized 1053 nm.

Keywords

Thermal effects; Nd: YLF laser crystal; Thermal stress; Heat dissipated power in crystal; End-diode pumped

Introduction

Thermal lens effect was discovered by Gordon et al. [1] in 1964. When a laser crystal is absorbed pumping light energy, fluorescent light is produced. A part of pumping light will be converted into thermal energy and created a variation in refraction index and mechanical properties for laser crystal [2,3].

Thermal distortion is caused when a field of a temperature gradient formed in the crystal. The thermal effects will make laser crystal as a thermal lens. This lens had most limitations the laser beam quality and resonator stability range. There are different ways to reduce thermal lens effects such as, by using composite crystal and designing the variable configuration resonator [2].

Nd: YLF auniaxial, birefringent crystal with two main lasing line in the 1 μm wavelength region namely 1047 nm and 1053 nm both the π and σ polarized. To minimize the effects of thermal lens and stress induced birefringence, Nd: YLF crystal was used as laser material because of it good thermo optical properties [3,4].

The aim of this paper is to present theoretical results for studying the effects of rod crystal dimensions on the thermal stress for π 1047 nm and σ 1053 nm polarization in a cut Nd: YLF crystal with 20 W end pumping power.

Materials and Methods

Proposed geometry and basic equations

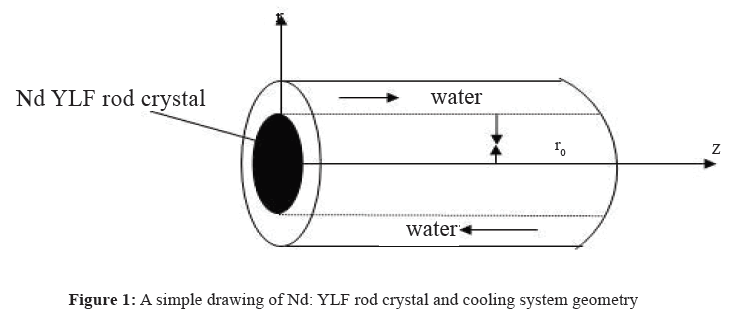

The proposed geometry consists of Nd: YLF crystal rod, whose axis corresponds with the pump symmetry axis, with a radius ro which is surrounded by a cylindrical with water for cooling, which leads to conduction heat transfer from rod surface to the ambient medium. The schematic figure of the rod and cooling system geometry is shown in Figure 1.

The absorbed power Pa in crystal is given by [2]:

Pa=ɳaPin (1)

ɳa=1-exp-αL (2)

where Pin and ɳa are the fraction of optical input power and the absorption efficiency respectively, is the absorption coefficient of the laser crystal at a wavelength emitted by the laser diode, and L is the crystal length.

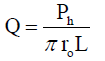

In the case of diode pumped, the heat dissipated power Ph is given by:

Ph=ɳhPa (3)

The fractional thermal load in the crystal ɳh can be calculated

(4)

(4)

where λP is the pump wave length and λL is the laser wave length.

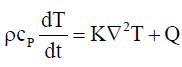

The heat conduction equation is given by [5]:

(5)

(5)

where ρ is the density of the material (kg m-3), CP is the specific heat (J kg-1 K-1), T is the temperature in (K), t is the time (s), K is the thermal conductivity (Wm-1 K-1), ∇ is the gradient operator, and Q is the heat generated in crystal per unit volume in (W/m-3) [6]. Eq. 5 can be solved at steady - state gives, the temperature at any point along a radius of length r (radial temperature), at the boundary condition T(ro) for r=ro where T(ro)=Ts is the temperature at the surface of the rod, then:

(6)

(6)

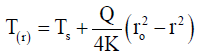

where Ts is the temperature at the surface of the crystal given by:

(7)

(7)

where h is the surface heat transfer coefficient, TF is the coolant temperature, and A is the surface area of the crystal rod. The uniform heat generated per unit volume is given by:

(8)

(8)

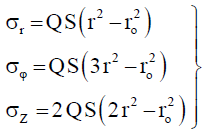

Thermal stress deformation occurs as the temperature of material increases since the vibration of the constituent atoms or molecule's increases. This effect causes the material to expand. When this expansion is constrained it

(9)

(9)

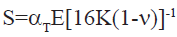

where σr, σφ, σz are radial, tangential and axial stress respectively, and S is given by:

(10)

(10)

where αT is the thermal coefficient of expansion; E is young's modules and ν is Poisson’s ratio. The photo elastic effect is a minor importance in Nd: YLF because of its strong natural birefringence.

Results and Discussion

In our previous works [7,8], general theoretical calculations were established to study and determine the variations of surface temperature, refractive index and the focal length for π (1047 nm) and σ (1053 nm) polarization in a cut Nd: YLF crystal with 20 W end pumping power using the model under study in Figure 1 and the information and essential parameters for the crystal in Table 1 [2].

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Thermal conductivity K | 0.06 (W/cmK) | Elastic modulus | 7.5 × 1010 (N/m2) |

| Peak absorption coefficient a(for 1% Nd) | π: 10.8 cm-1; s: 3 cm-1 | Surface heat transfer coefficient | 1.8 W/cm2K |

| Refractive indices no | π: 1.477; s: 1.448 | Crystal radius ro | 0.15 cm |

| Thermo-optical coefficient dn/dt | π: -4.3 × 10-6 K-1 s: -2.0 × 10-6 K-1 |

- | - |

Table 1: Basic parameters of Nd: YLF laser crystal [2]

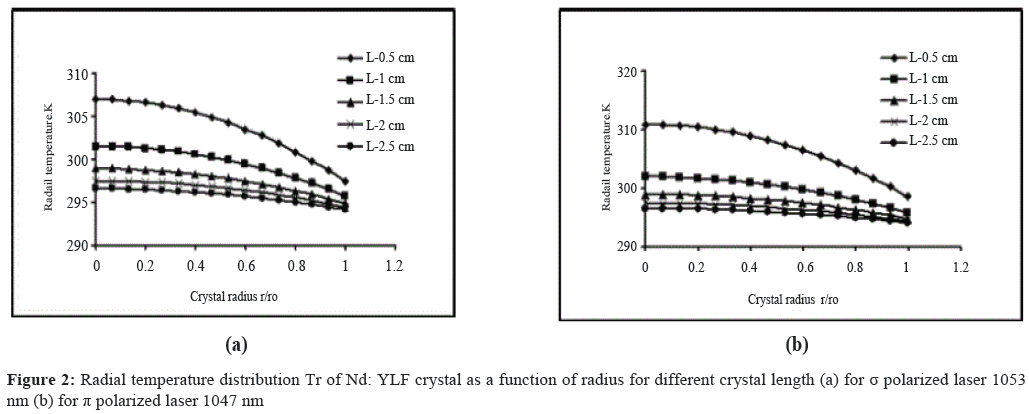

According to Eq. 6, the radial temperature distribution as a function of a radius for Nd: YLF crystal for different values of crystal length is shown in Figure 2.

It can be seen that radial temperature with a parabolic profile, has a maximum temperature in the center of crystal and of minimum value on the surface of crystal. Also, by increasing the crystal length, the radial temperature begins to converge in values.

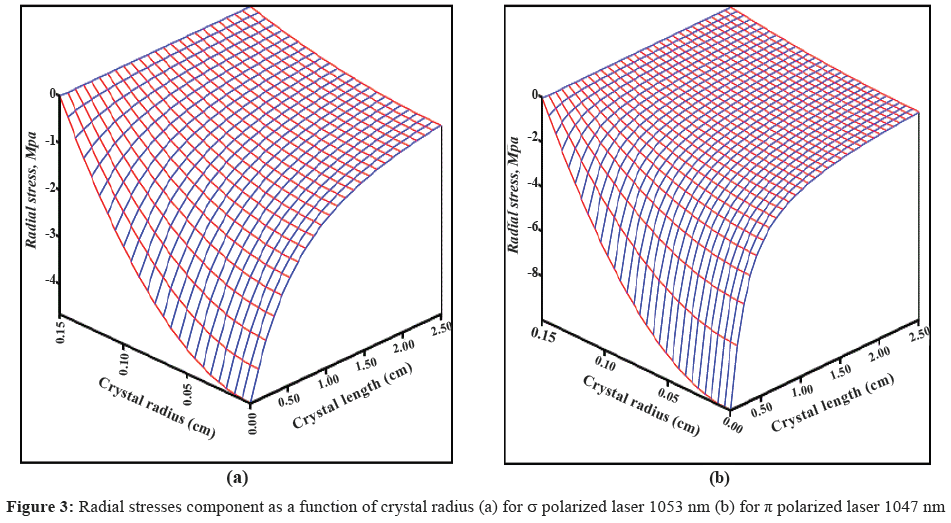

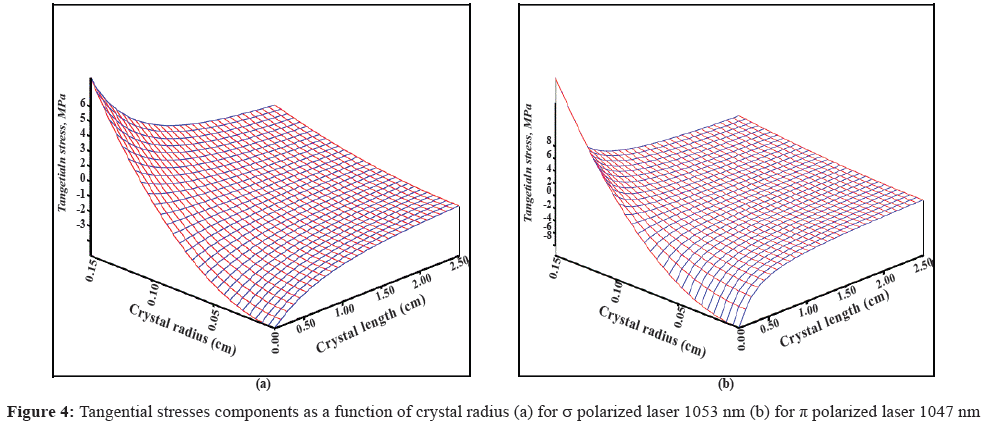

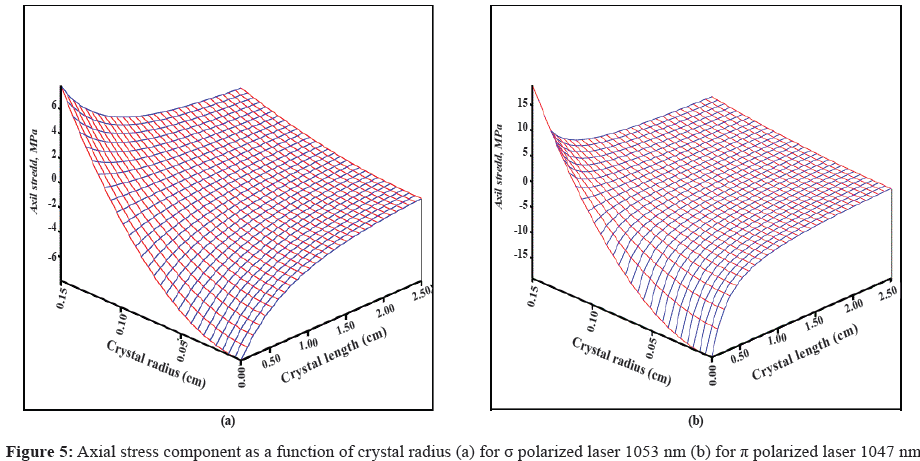

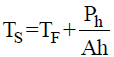

The thermal stress components are studied for different crystal length for and polarized using Eq. 9 as shown in Figures 3-5.

It is found that the stress distribution profile is parabolic for all the three compounds. The center of the rod is under compression (negative value) while the surface of the rod is under tension (positive value). The stress compound is affected by the crystal length while it decreases when the crystal length increases; the stress distribution of σ polarized 1053 nm is less than π polarized 1047 nm.

Conclusion

The numerical calculation in the present work has produced some exact results, which have classified the importance of thermo-optic effect for Nd: YLF crystal. When the crystal length is increased, the radial temperature begins convergence in values, furthermore, the temperature at the center of rod decreases. The center of rod under compression, the radial stress component vanishes at the rod surface, and the tangential and axial stress component had the same magnitude on the pumped rod surface reaching a maximum value. Also, the results are showing that thermal stress effects of π polarized is stronger than σ polarized.

References

- Gordon JP, Leite RCC, Moore RS, Porto SPS, Whinnery JR (1965) Long-transient effects in laser with inserted liquid samples. J Appl Phys 36: 3-8.

- Koechner W, Bass M (2003) Solid-State Lasers: A Graduate Text. Springer, New York.

- Ma Z, Gao J, Li D, Li J, Wu N, et al. (2008) Thermal stress effects of the diode end pumped Nd:YLF Slab. Opt Commun 281: 3522-3526.

- Clarkson WA, Hardman PJ, Hanna DC (1998) High power diodebar endpumped Nd: YLF laser at 1.053 μm. Opt Lett 2: 1363-1365.

- Carslaw HS, Jaeger JC (1959) Conduction of Heat in Solids. (2ndedn), Oxford University Press, London.

- Timoshenko S, Goodier JN (1982) Theory of Elasticity. (3rdedn), McGraw-Hill, Singapore.

- Yahya KA, Hussein OA, Mustafa OH (2016) Effect of crystal length on the thermal characteristic in Nd: YLF laser with 20 W diode pumped. AIP Conf Proc, Istanbul,Turkey.

- Yahya KA, Hussein OA, Mustafa OH (2013) Thermal focal length of Nd: YLF laser rod crystal at 797 nm and 792 nm diode-end pump. Adv. Appl. Sci. Res 4: 400-404.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences