Effect of pre-harvest foliar application of micro nutrients and various storage conditions on shelf life of peach (Prunus persica (L.) Batsch)

Mitali Goutam*, Kiran Kour, Parshant Bakshi, Sarabdeep Kour, and M.Iqbal Jeelani

Division of Fruit Science, Faculty of Agriculture, Sher-e-Kashmir University of Agricultural Sciences and Technology of Jammu, India

- Corresponding Author:

- Mitali Goutam

Division of Fruit Science

Sher-e-Kashmir University of Agricultural Sciences and Technology of Jammu

Jammu, India

E-mail: goutammitali1@gmail.com

Received: February 15, 2021; Accepted: March 05, 2021; Published: March 15, 2021

Citation: Goutam M, Kour K, Bakshi P, Kour S, Jeelani MI (2021) Effect of Pre-harvest Foliar Application of Micro Nutrients and Various Storage Conditions on Shelf life of Peach (Prunus persica (L.) Batsch). J Plant Sci Agri Res Vol.5 No.1:54

Abstract

Present investigation were carried out on Shan-e- Punjab cultivar of peach (Prunus persica L.) to assess the effect of pre harvest application of calcium nitrate, silver nitrate and zinc sulphate on various storage conditions during 2015-2016. The experiment was laid out in Randomized Block Design with ten treatments consisting of foliar spray of calcium nitrate (1.0 %, 1.5 %, 2.0 %), silver nitrate (0.005 %, 0.010 %, 0.015%), zinc sulphate (0.25 %, 0.5%, 0.75%) and control (water spray) replicated thrice. The foliar application of nutrients applied at different concentrations of calcium nitrate and zinc sulphate neutralized with lime was sprayed twice i.e. immediately after petal fall stage and two weeks before harvest, whereas silver nitrate was sprayed first five weeks before harvest and second three weeks after first spray. Fruits were harvest at maturity stage, some fruits are packed in LDPE polybags having diameter 0.3 mm were stored under refrigerator conditions (3+-20 C and 85-95% RH) for 18 days followed by stored under ambient conditions for 6 days. On the other hand unpacked fruits were also stored under refrigerator conditions for 9 days and under ambient conditions for 3 days. Fruits treated with 2.0% calcium nitrate and packed in polybags effectively reduced physiological loss in weight (6.72%), decay loss (52.14%) and increase TSS content(13.16 0B) up to 18 days under refrigerate condition.

Keywords

Peach; LDPE; Calcium nitrate; Silver nitrate; Zinc sulphate

Introduction

Peach (Prunus persica (L.) Batsch) is one of the most important stone fruit belong to the family Rosaceae and sub family Prunoidae and gaining popularity in mid to high hill temperate zone owing to global climate change as it requires low chilling hours than other major temperate fruit crops. China is widely held to be the native land of peaches. The main peach producing countries are Italy, USA, Greece, Spain, France, Russia and China. Now a days, it is being grown in the mid-hill zones of the Himalayas extending from Jammu and Kashmir to Khalsi hills at an altitude of 1000 m-2000 m above mean sea level. A distinct group of cultivar requires low chilling hours for bud burst and growth is known as low chill peach. The cultivation of low chill peaches confined to the subtropical area of North India including Uttar Pradesh, Uttarakhand, Punjab, Jammu and Kashmir and Haryana. Presently Sharbati, Saharanpur, Prabhat, Florada prince and Shan-e-Punjab and Early grand are popular cultivars in the area. Shan-e-Punjab is one of the most important temperate fruit primarily cultivated in Punjab and Jammu and Kashmir. Peach is a climacteric fruit and it continues to respire even after harvest and leads to heavy post-harvest losses which can be seen in terms of shrinkage ultimately rendering to the softening of the fruits. After softening, fruit is susceptible to physical injury and pathogen attack and become unfit for storage. The cultivar Shan-e-Punjab is promising among the other peach cultivars grown in Jammu region and has gained popularity among fruit growers because of its large-sized fruits with attractive red blushed yellow colour. It is delicious, juicy with high productivity and remunerative value suitable for both canning and dessert purpose. It ripens in the 2nd week of May and has a very short shelf life and is subject to senescence and softening immediately after harvest and cannot withstand transport or storage for long period. Various attempts have been made to increase the Shelf-life and quality of fruits with the pre-harvest treatments. Calcium is known to strengthen the structure of cells by maintaining the fibrillar packaging in the cell walls thus reinforcing the cell to cell contact which is related to the formation of calcium pectate and counteracts the pectin methylesterase activity [1]. Zinc has been implicated in the functioning of a large number of enzymes and influences the quality and shelf-life of many fruits as reported by various workers [2]. In recent years, silver ions as a potent anti-ethylene agent have been used effectively to increase the shelf life of fruits [3,4]. Found that the silver ion is quite effective in inhibiting ethylene synthesis and ripening process [5].

Materials and Methods

The present study was carried out at a private orchard near Jakh district Samba during 2015-2016. The pre-harvest foliar spray of calcium nitrate, silver nitrate and zinc sulphate neutralized with lime was sprayed twice i.e. immediately after petal fall stage and two weeks before harvest whereas silver nitrate was sprayed first five weeks before harvest and second three weeks after the first spray on 10-year-old trees of peach cv. Shan-e-Punjab. The experiment has consisted of 10 treatments viz.T1: calcium nitrate (1%), T2: calcium nitrate (1.5%), T3: calcium nitrate (2%), T4: silver nitrate, T5: silver nitrate, T6: silver nitrate, T7: zinc sulphate (0.25%), T8: Zinc sulphate (0.5%), T9: Zinc sulphate (0.75%) and T10: Control (water spray) with three replication in randomized block design. The fruits were harvest at mature stage. From every treatment, some fruits are packed in polybag and some are not and they are kept under refrigerator condition and ambient conditions to calculate physiological loss in weight, decay loss and TSS content in peach. Under ambient storage conditions, packed fruit lost its acceptability after 6 days while under refrigerated conditions packed fruit acceptability declined after 18 days. On the other hand, ambient stored unpacked fruit lost its acceptability after 3 days while under refrigerated conditions unpacked fruit acceptability declined after 9 days. The Physiological Loss in Weight (PLW) of the fruit was determined with the formula given by [6] on the basis of the initial weight of the fruit and loss in weight that occurred and was expressed in percent.

Physiological loss in weight (%) = Initial weight − Final weight ÷ Initial weight ×100

The Total Soluble Solids (TSS) of the fruit juice was recorded with the help of Erma hand refractometer (0°B-32°B) as per standard procedure given in [7] and expressed as degree Brix (°B) at room temperature. A temperature correction was applied when the readings were taken at a temperature other than 20°C. The refractometer was calibrated with distilled water before use.

Decay loss was measured on each date of observation, the decayed fruits were weighted separately and decay loss was estimated by using the following formula suggested by [6].

Decay loss (%) =Weight of decay fruits ÷ Weight of decay fruits ×100

Results and Discussion

Physiological loss in weight

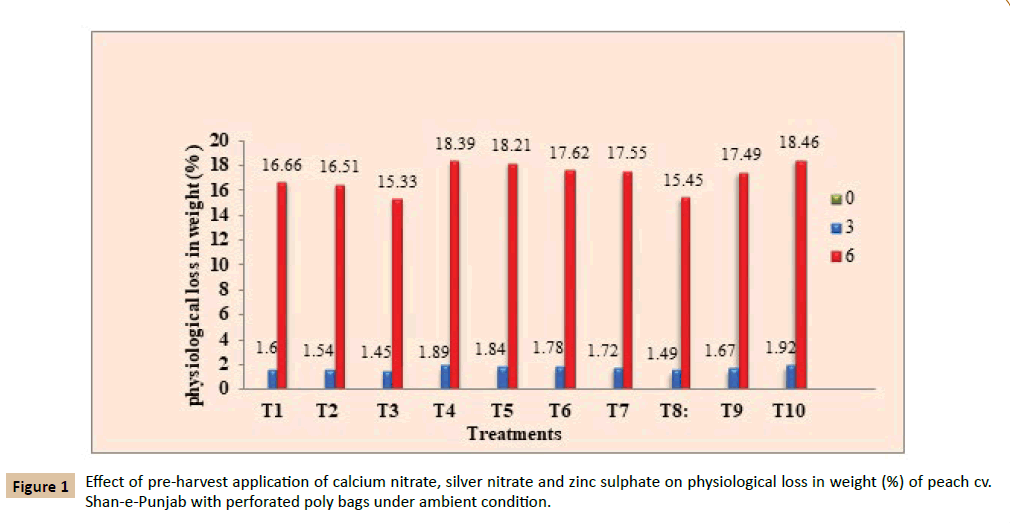

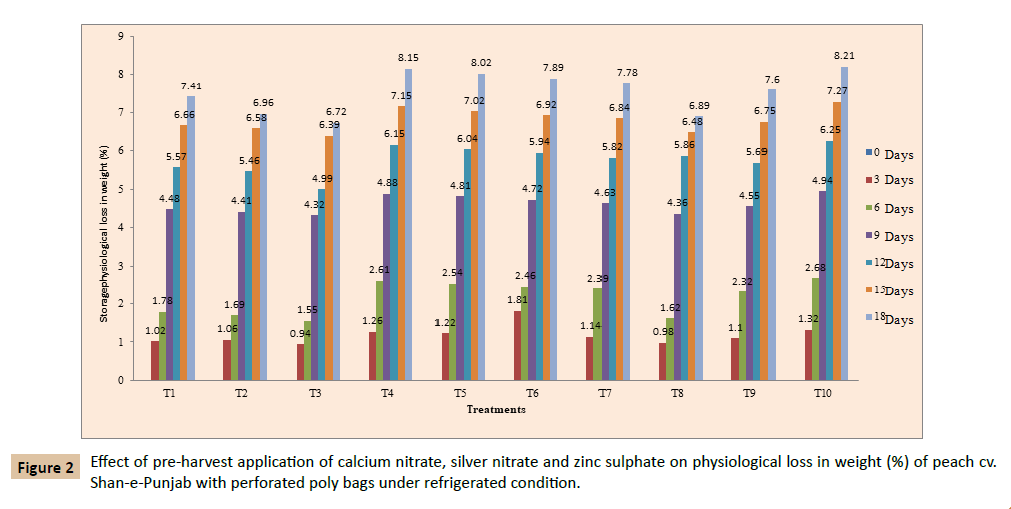

The data pertaining to Physiological Loss in Weight (PLW) of fruits packed in perforated polybags as influenced by storage conditions (ambient and refrigerated), is given in Figure 1 and Figure 2 in ambient storage conditions, fruit lost its acceptability after 6 days while under refrigerated conditions the fruit acceptability declined after 18 days. The fruits stored under the ambient condition in perforated polybags and treated with 2% calcium nitrate (T3) showed minimum physiological loss in weight (15.33%) after 6 days of storage while those stored under refrigerated condition in perforated polybags showed minimum loss in weight (6.72%) in fruits treated with 2% calcium nitrate (T3) after 18 days of storage.

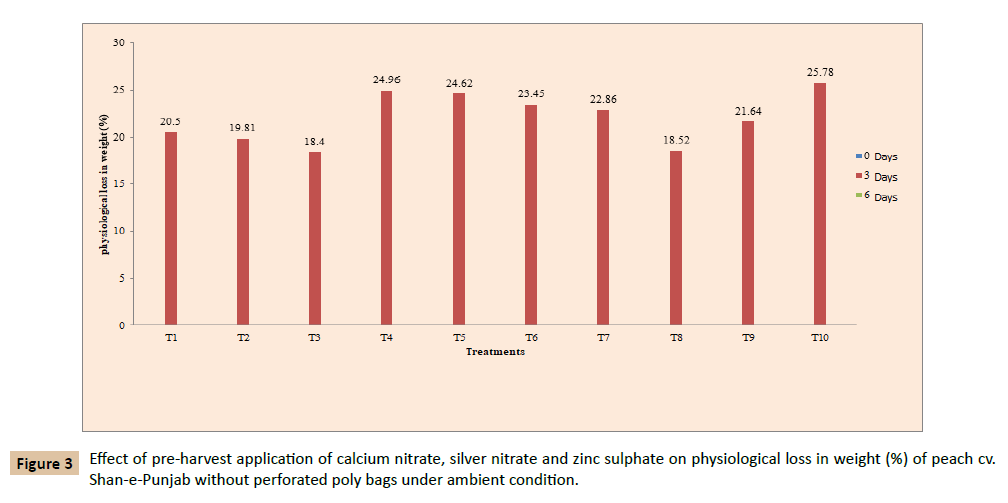

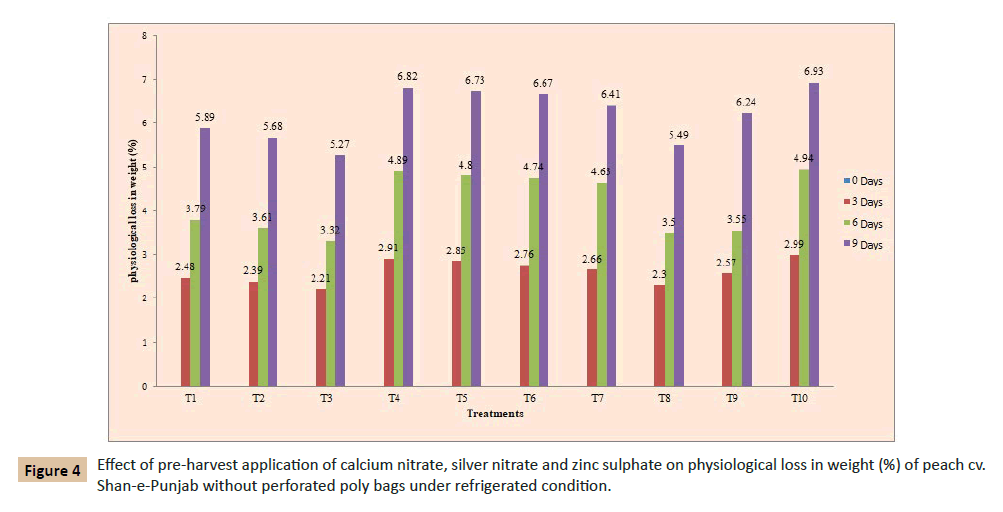

The data pertaining to Physiological Loss in Weight (PLW) of unpacked fruits as influenced by storage conditions (ambient and refrigerated), is given in Figure 3 and Figure 4 in ambient storage conditions, fruit lost its acceptability after 3 days while under refrigerated conditions the fruit acceptability declined after 9 days. PLW was more under ambient conditions than refrigerated conditions. The unpacked fruits stored under ambient conditions and treated with 2% calcium nitrate (T3) showed minimum physiological loss in weight (18.40%) after 3 days of storage than those unpacked fruits stored under refrigerated condition, which showed minimum loss in weight (5.27%) in fruits treated with 2% calcium nitrate (T3) after 9 days of storage. The physiological loss in weight increased with the advancement of the storage period under all treatments. This may pertain to evaporation and transpiration losses as reported in peach. Another reason was due to prevention of cellular disintegration by maintaining protein and nucleic acid synthesis and there by delaying senescence. [8] observed reduced fruit weight loss in calcium treated Nitaka pear fruits. [9] that the lowest physiological loss in weight in papaya was obtained in fruits sprayed with 2% calcium nitrate and maximum under control.

Decay loss

The data pertaining to decay loss (%) of fruits packed in perforated polybags as influenced by storage conditions (ambient and refrigerated) and storage intervals are given in Table 1 and Table 2. In ambient storage conditions, fruit lost its acceptability after 6 days while in refrigerated conditions, the fruit acceptability declined after 18 days. Decay loss was more under ambient conditions than refrigerated condition. The fruits stored under the ambient condition in perforated polybags and treated with 2.0% calcium nitrate (T3) showed minimum decay loss (26.75%) after 6 days of storage, while the minimum losses in those stored under refrigerated condition (52.14%) with 2% calcium nitrate (T3) after 18 days of storage under control (T10).

Table1: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on decay loss (%) of peach cv. Shan-e-Punjab with perforated poly bags under ambient condition.

| Treatments | Storage interval (days) | |||

|---|---|---|---|---|

| 0 | 3 | 6 | Mean | |

| Ambient condition | ||||

| T1: Calcium nitrate (1.0%) | 0 | 26.53 -5.15 |

30.43 -5.5 |

28.48 |

| T2: Calcium nitrate (1.5%) | 0 | 26.02 -5.1 |

29.58 -5.43 |

27.8 |

| T3: Calcium nitrate (2.0%) | 0 | 23.15 -4.81 |

26.75 5.17 |

24.95 |

| T4: Silver nitrate (0.005%) | 0 | 35.25 -4.82 |

38.25 6.18 |

36.75 |

| T5: Silver nitrate (0.01%) | 0 | 34.86 -5.9 |

37.36 -6.11 |

36.11 |

| T6: Silver nitrate (0.015%) | 0 | 32.49 -5.7 |

35.49 -5.95 |

33.99 |

| T7: Zinc sulphate (0.25%) | 0 | 32.21 -5.6 |

35.14 -5.26 |

33.67 |

| T8: Zinc sulphate (0.5%) | 0 | 25.27 -5.02 |

27.72 -5.26 |

26.49 |

| T9: Zinc sulphate (0.75%) | 0 | 32.53 -5.7 |

33.47 -5.78 |

33 |

| T10: Control | 0 | 41.02 -6.4 |

41.53 -6.44 |

41.27 |

| Mean | 30.93 | 33.57 | ||

C.D. (p ≤ 0.05) Storage interval (S): 0.09; Treatments (T): 0.11; S × T: 0.13 Figures Values in parenthesis are square root transformed value

Table 2: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on decay loss (%) of peach cv. Shan-e-Punjab with perforated poly bags under refrigerated condition.

| Treatments | Storage interval | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | Mean | |

| Refrigerated condition | ||||||||

| T1: Calcium nitrate (1.0%) | 0 | 0 | 9.62 | 11.22 | 24.56 | 47.23 | 59.45 | 21.72 |

| T2: Calcium nitrate (1.5%) | 0 | 0 | 9.43 | 10.53 | 22.43 | 45.36 | 58.26 | 20.85 |

| T3: Calcium nitrate (2.0%) | 0 | 0 | 9.11 | 10.23 | 20.24 | 42.45 | 52.14 | 19.16 |

| T4: Silver nitrate (0.005%) | 0 | 0 | 9.84 | 12.64 | 36.32 | 60.56 | 72.35 | 27.38 |

| T5: Silver nitrate (0.01%) | 0 | 0 | 9.8 | 12.59 | 34.68 | 58.78 | 70.15 | 26.57 |

| T6: Silver nitrate (0.015%) | 0 | 0 | 9.76 | 12.51 | 31.43 | 56.47 | 67.48 | 25.37 |

| T7: Zinc sulphate (0.25%) | 0 | 0 | 9.72 | 11.68 | 27.57 | 54.51 | 62.86 | 23.76 |

| T8: Zinc sulphate (0.5%) | 0 | 0 | 9.26 | 10.46 | 20.36 | 43.31 | 53.26 | 19.52 |

| T9: Zinc sulphate (0.75%) | 0 | 0 | 9.68 | 11.39 | 2.41 | 52.7 | 61.02 | 19.6 |

| T10: Control | 0 | 0 | 9.88 | 11.71 | 39.82 | 64.49 | 74.67 | 28.65 |

| Mean | 9.61 | 11.49 | 25.98 | 52.58 | 63.16 | |||

C.D. (p ≤ 0.05), Storage interval (S) : 0.17; Treatment (T) : 0.09; S × T: 0.23

Figures in parenthesis are square-root transformed value

The decay loss (%) of unpacked fruits influenced by storage conditions (ambient and refrigerated) and storage intervals is given in Table 3 and Table 4. Under ambient storage conditions, unpacked fruit lost its acceptability after 3 days of storage while under refrigerated conditions the acceptability declined after 9 days. Decay loss was more under ambient conditions as compared to refrigerated condition. The fruits stored under ambient conditions without polybags treated with 2% calcium nitrate (T3) showed minimum decay loss (35.68%) after 3 days of storage, while the minimum losses were recorded in 2% calcium nitrate (T3) in those stored under refrigerated condition (40.41%) after 9 days of storage. Calcium increases the synthesis of phytoalexins and phenolic compounds which are involved to resist the fungal attack and it also reduces the risk of micro- cracks in the cuticle which is known to be the direct site of fungal infection [10] [11] treatments in strawberry fruits reduced the decay loss percentage. These results are also in agreements with guava and [12] in kinnow.

Table 3: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on decay loss (%) of peach cv. Shan-e-Punjab without perforated poly bags under ambient condition.

| Treatments | Storage interval (days) | |

|---|---|---|

| 0 | 3 | |

| Ambient condition | ||

| T1: Calcium nitrate (1.0%) | 0 | 40.25(6.34) |

| T2: Calcium nitrate (1.5%) | 0 | 38.45(6.20) |

| T3: Calcium nitrate (2.0%) | 0 | 35.68(5.97) |

| T4: Silver nitrate (0.005%) | 0 | 50.31(7.09) |

| T5: Silver nitrate (0.01%) | 0 | 49.41(7.02) |

| T6: Silver nitrate (0.015%) | 0 | 47.45(6.88) |

| T7: Zinc sulphate (0.25%) | 0 | 46.65(6.75) |

| T8: Zinc sulphate (0.5%) | 0 | 37.24(6.10) |

| T9: Zinc sulphate (0.75%) | 0 | 42.75(4.65) |

| T10: Control | 0 | 52.53(7.24) |

| Mean | 44.07 | |

| C.D. (p ≤ 0.05) | 0.1 | |

Figures in parenthesis are square root transformed value

Table 4: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on decay loss (%) of peach cv. Shan-e-Punjab without perforated poly bags under refrigerated condition.

| Treatments | Storage interval (days) | ||||

|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | Mean | |

| Refrigerated condition | |||||

| T1: Calcium nitrate (1.0%) | 0 | 11.39 -3.37 |

21.32 -4.61 |

44.59 -6.67 |

25.76 |

| T2: Calcium nitrate (1.5%) | 0 | 11.34 -3.36 |

20.83 -4.56 |

42.41 -6.51 |

24.86 |

| T3: Calcium nitrate (2.0%) | 0 | 11.21 -3.34 |

20.67 -4.54 |

40.41 -6.35 |

24.09 |

| T4: Silver nitrate (0.005%) | 0 | 12.79 -3.57 |

21.83 -4.67 |

53.29 -7.3 |

29.3 |

| T5: Silver nitrate (0.01%) | 0 | 12.73 -3.56 |

21.72 -4.66 |

51.32 -7.16 |

28.59 |

| T6: Silver nitrate (0.015%) | 0 | 12.61 -3.55 |

21.67 -4.65 |

49.79 -7.05 |

28.02 |

| T7: Zinc sulphate (0.25%) | 0 | 12.59 -3.45 |

21.52 -4.63 |

47.66 -6.9 |

27.25 |

| T8: Zinc sulphate (0.5%) | 0 | 11.27 -3.35 |

20.71 -4.55 |

40.36 -6.35 |

24.11 |

| T9: Zinc sulphate (0.75%) | 0 | 12.42 -3.52 |

21.46 -4.63 |

45.53 -6.74 |

26.47 |

| T10: Control | 0 | 12.86 -3.58 |

21.89 -4.67 |

57.26 -7.56 |

30.67 |

| Mean | 12.12 | 21.36 | 47.26 | ||

C.D. (p ≤ 0.05) Storage interval (S): 0.18; Treatments (T): 0.14; S × T: 0.22

Figures in parenthesis are square root transformed value.

TSS

It can be inferred from the data given in Table 5 and Table 6 that the total soluble solid of the fruits packed in perforated polybags, showed an increasing trend with the advancement in storage intervals. The maximum TSS (14.24°B) was observed in fruits treated with 2% calcium nitrate (T3) after 6 days of storage under ambient conditions, while minimum TSS (12.32°B) was recorded in untreated fruits. The fruits stored under refrigerated conditions also showed a significant increase in TSS up to 18 days of storage, whereas maximum TSS (13.16°B) was recorded in 2% calcium nitrate (T3) treated fruits, thereafter the TSS of fruits declined at 18 days after storage and minimum TSS was recorded in untreated fruits (10.71°B). It can be inferred from the data in Table 7 and Table 8 that total soluble solids of unpacked fruits, showed a progressive increase with the advancement in the storage period. The maximum TSS (14.16°B) was observed in unpacked fruits which are treated with 2% calcium nitrate (T3), after 3 days of storage under ambient conditions, while minimum TSS (12.21°B) was recorded in untreated fruits. There was a significant increase in TSS of unpacked fruits stored under refrigerated conditions up to 6 days of storage, thereafter the TSS declined at 9 days of storage interval. The maximum TSS (12.66°B) was recorded in 2% calcium nitrate (T3), after 6 days of storage under refrigerated conditions, whereas minimum TSS (10.31°B) was recorded in untreated fruits. The effect of calcium in increasing the total soluble solids content of fruits was probably due to slowing down respiration and metabolic activities, hence retarding the ripening process and use of metabolites, resulting in lowering of total soluble solids in fruits [13]. The increases in TSS up to a certain period signified the period of active synthesis of carbohydrates in fruits. Singh and Tiwari eported an increase in total soluble solids in guava cv. Sardar upto 10 days of cold storage.

Table 5: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on TSS °B) of peach cv. Shan-e-Punjab with perforated poly bags under ambient condition.

| Treatments | ||||

|---|---|---|---|---|

| Storage interval (days) | ||||

| 0 | 3 | 6 | Mean | |

| Ambient condition | ||||

| T1: Calcium nitrate (1.0%) | 11.2 | 11.39 | 13.29 | 11.96 |

| T2: Calcium nitrate (1.5%) | 11.84 | 11.96 | 13.46 | 12.42 |

| T3: Calcium nitrate (2.0%) | 12.36 | 12.46 | 14.24 | 13.02 |

| T4: Silver nitrate (0.005%) | 10.16 | 10.4 | 12.51 | 11.02 |

| T5: Silver nitrate (0.01%) | 10.42 | 10.63 | 12.59 | 11.21 |

| T6: Silver nitrate (0.015%) | 10.84 | 10.91 | 12.63 | 11.46 |

| T7: Zinc sulphate (0.25%) | 11.32 | 11.55 | 13.12 | 11.99 |

| T8: Zinc sulphate (0.5%) | 12.16 | 12.31 | 14.13 | 12.86 |

| T9: Zinc sulphate (0.75%) | 11.75 | 11.87 | 13.19 | 12.27 |

| T10: Control | 10 | 10.23 | 12.32 | 10.85 |

| Mean | 11.2 | 11.37 | 13.14 | |

C.D. (p ≤ 0.05)Storage interval (S): 0.13; Treatment (T): 0.43; S × T : 0.48

Table 6: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on TSS (°B) of peach cv. Shan-e-Punjab with perforated poly bags under refrigerated condition.

| Treatments | Storage interval | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | Mean | ||

| Refrigerated condition | |||||||||

| T1: Calcium nitrate (1.0%) | 11.2 | 11.32 | 11.41 | 12.16 | 12.22 | 12.31 | 12.46 | 11.86 | |

| T2: Calcium nitrate (1.5%) | 11.84 | 11.96 | 11 | 12.23 | 12.36 | 12.41 | 12.53 | 12 | |

| T3: Calcium nitrate (2.0%) | 13.36 | 12.49 | 12.57 | 12.72 | 12.81 | 12.92 | 13.16 | 12.86 | |

| T4: Silver nitrate (0.005%) | 10.16 | 10.36 | 10.46 | 10.68 | 10.72 | 10.81 | 10.89 | 10.58 | |

| T5: Silver nitrate (0.01%) | 10.42 | 10.56 | 10.66 | 10.71 | 10.8 | 10.89 | 10.96 | 10.71 | |

| T6: Silver nitrate (0.015%) | 10.84 | 10.9 | 10.95 | 11.23 | 11.36 | 11.47 | 11.61 | 11.19 | |

| T7: Zinc sulphate (0.25%) | 11.32 | 11.45 | 11.52 | 11.73 | 11.82 | 11.91 | 11.99 | 11.67 | |

| T8: Zinc sulphate (0.5%) | 12.16 | 12.27 | 12.36 | 12.59 | 12.7 | 12.82 | 12.93 | 12.54 | |

| T9: Zinc sulphate (0.75%) | 11.75 | 11.81 | 11.91 | 12.09 | 12.16 | 12.29 | 12.33 | 12.04 | |

| T10: Control | 10 | 10.24 | 10.34 | 10.49 | 10.58 | 10.66 | 10.71 | 10.43 | |

| Mean | 11.3 | 11.33 | 11.31 | 11.66 | 11.75 | 11.84 | 11.95 | ||

C.D.(p ≤ 0.05) Storage interval (S): 0.51; Treatment (T) : 0.23; S × T: 0.68

Table 7:Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on TSS (°B) of peach cv. Shan-e-Punjab without perforated polybags under ambient condition.

| Treatments | Storage interval (days) | ||

|---|---|---|---|

| 0 | 3 | Mean | |

| Ambient condition | |||

| T1: Calcium nitrate (1.0%) | 11.2 | 13.26 | 12.23 |

| T2: Calcium nitrate (1.5%) | 11.84 | 13.41 | 12.62 |

| T3: Calcium nitrate (2.0%) | 12.36 | 14.16 | 13.36 |

| T4: Silver nitrate (0.005%) | 10.16 | 12.48 | 11.32 |

| T5: Silver nitrate (0.01%) | 10.42 | 12.51 | 11.46 |

| T6: Silver nitrate (0.015%) | 10.84 | 12.6 | 11.72 |

| T7: Zinc sulphate (0.25%) | 11.32 | 13.1 | 12.21 |

| T8: Zinc sulphate (0.5%) | 12.16 | 14 | 13.08 |

| T9: Zinc sulphate (0.75%) | 11.75 | 13.09 | 12.42 |

| T10: Control | 10 | 12.21 | 11.1 |

| Mean | 11.2 | 13.08 | |

C.D. (p ≤ 0.05) Storage interval (S): 0.78; Treatment (T): 1.10; S × T: 1.21

Table 8: Effect of pre-harvest application of calcium nitrate, silver nitrate and zinc sulphate on TSS (°B) of peach cv. Shan-e-Punjab without perforated polybags under refrigerated condition.

| Treatments | Storage interval (days) | ||||

|---|---|---|---|---|---|

| 0 | 3 | Mean | |||

| Ambient condition | |||||

| T1: Calcium nitrate (1.0%) | 11.2 | 13.26 | 12.23 | ||

| T2: Calcium nitrate (1.5%) | 11.84 | 13.41 | 12.62 | ||

| T3: Calcium nitrate (2.0%) | 12.36 | 14.16 | 13.36 | ||

| T4: Silver nitrate (0.005%) | 10.16 | 12.48 | 11.32 | ||

| T5: Silver nitrate (0.01%) | 10.42 | 12.51 | 11.46 | ||

| T6: Silver nitrate (0.015%) | 10.84 | 12.6 | 11.72 | ||

| T7: Zinc sulphate (0.25%) | 11.32 | 13.1 | 12.21 | ||

| T8: Zinc sulphate (0.5%) | 12.16 | 14 | 13.08 | ||

| T9: Zinc sulphate (0.75%) | 11.75 | 13.09 | 12.42 | ||

| T10: Control | 10 | 12.21 | 11.1 | ||

| Mean | 11.2 | 13.08 | |||

C.D. (p ≤ 0.05) Storage interval (S): 0.78; Treatment (T): 1.10; S × T: 1.21

Discussion

Physiological loss in weight

The physiological loss in weight increased with the advancement of the storage period under all treatments. This may pertain to evaporation and transpiration losses as reported in peach. Another reason was due to the prevention of cellular disintegration by maintaining protein and nucleic acid synthesis and thereby delaying senescence observed reduced fruit weight loss in calcium treated Nitaka pear fruits [8].

[9] found that the lowest physiological loss in weight in papaya was obtained in fruits sprayed with 2% calcium nitrate and maximum under control.

Decay loss

Calcium increases the synthesis of phytoalexins and phenolic compounds which are involved to resist the fungal attack and it also reduces the risk of micro-cracks in the cuticle which is known to be the direct site of fungal infection [10]. That calcium chloride treatments in strawberry fruits reduced the decay loss percentage [11]. These results are also in agreements with the in guava and Lal et al. in kinnow [12].

TSS

The effect of calcium increasing the total soluble solids content of fruits was probably due to slowing down respiration and metabolic activities, hence retarding the ripening process and use of metabolites, resulting in lowering of total soluble solids in fruits [13]. The increases in TSS up to a certain period signified the period of active synthesis of carbohydrates in fruits [14] reported an increase in total soluble solids in guava cv. Sardar upto 10 days of cold storage.

Conclusion

It can be concluded that fruits of peach cv. Shan-e-Punjab treated with (2%) calcium nitrate showed maximum yield, best quality and minimum physiological loss in weight and prove to be best in enhancing the shelf life of fruits.

References

- Bakashi P. (2002) Effect of foliar application of potassium, zinc and boron on the mango cv. Dashehari. J Agri Tech2:415-419.

- Chaitany CG, Kumar G, Raina BL, Muthoo AK (1997) Effect of Zinc and Boron on the Shelf Life of Guava Cv. Sardar (Psidium guajava L.). Adv Plant Sci 10:45-50.

- Sandooja JK, Sharma RK, Singhrot RS, Singh JP (1986) Studies on shelf-life of different maturity stages of peach cv. Flordasum as affected by KMnO4 and AgNO3. Haryana J Hort Sci 10:75-76.

- Mahajan BVC, Chopra SK (1998) Effect of calcium and diaminozide on ethylene Production and softening of apple fruits Experientia. Indian J Hortic 35:43-44.

- Saltveit ME, Fradford KL Dilley, DR (1978) Silver ion inhibits ethylene synthesis and action in ripening fruits. J AmericanSociety Hort Sci 103:472.

- Srivastava MP, Tondon RN (1968) Influence of temperature in Botryoplodia rot of citrus and Sapodilla. Indian Pytopathol 21:195-197.

- AOAC. 1995 Official methods of Analysis (16th ed.). Association of Official Analytical Chemists, Washington, DC, USA.

- Moon B W, Lu WL, Zheng HL, Choi J S (2002) Effects of tree spray of liquid calcium compounds on the calcium content, quality and cell wall structure of “Jingfen” pear fruits. J Kor Soc Hort Sci 43:51-53.

- Ramakrishna M, Haribabu K, Reddy, YN, Purushotham K (2001) Effect of pre harvest application of calcium on physio- chemical changes during ripening and storage of papaya. Indian J Horti 58:228-231.

- Elmer PAG, Spiers TM, Wood PN (2000) Effect of pre-harvest foliar calcium spray on fruit calcium levels and brown root of peaches. J Crop Prot 26:11-18.

- Wojcik P, Lewandowski M (2003) Effect of calcium and boron sprays on yield and quality of Elsanta Strawberry.J Plant Nutri 26: 671-682.

- Lal D, Tripathi VK, Kumar S, Nayyer AM (2015) Effect of pre-harvest application of gibberelic acid, NAA and calcium nitrate on fruit drop, maturity and storage quality of kinnow mandarin. Res Envir Life Sci 8: 561- 564.

- Mahumud TMM, Eryani AL, Syed OSR, Mohammad ZAR Abdul R (2008) Effect of different concentration and application of calcium on storage life and physio-chemical characteristics of papaya (Carica papaya L.). American JAgri Biol Sci 3:526-533.

- Singh J, Tiwari JP(1994) Effect of calcium on the post-harvest quality of Guava (Psidium gaujava L.) cv. sardar. Progress horti 26:114-118.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences