ISSN : 2321-2748

American Journal of Phytomedicine and Clinical Therapeutics

Application of Microfluidic Technology in Pharmaceutical Analysis

Department of Pharmaceutical analysis, MLR Institute of Pharmacy, Dundigal, Hyderabad, Telangana, India

- *Corresponding Author:

- Chilukuri Revathi sreelekha

Department of Pharmaceutical analysis

MLR Institute of Pharmacy, Dundigal

Hyderabad, Telangana, India

E-mail: srilekha13.sl@gmail.com

Received Date: June 28, 2021; Accepted Date: July 16, 2021; Published Date: July 24, 2021

Citation: Sreelekha CR, Sahoo NK (2021) Application of Microfluidic Technology in Pharmaceutical Analysis. Am J Phytomed Clin Ther Vol.9 No.7:33.

Abstract

Microfluidic gadgets existing one-of-a-kind benefits for the development of effective medication provider bits, cell-free healthy protein synthesis systems, and also rapid strategies for straight drug testing. Contrasted to bulk approaches, by effectively controlling the geometries of the produced chip and the circulation rates of multiphase fluids, microfluidic modern technology makes it possible for the generation of very stable, consistent, mono dispersed particles with greater encapsulation performance. Given that the existing preclinical versions are inefficient drug displays for anticipating clinical outcomes, microfluidic systems might use a more rapid as well as affordable choice. The development of pharmaceutical logical methods represents one of the most significant aspects of medication growth. Recent advancements in micro fabrication and microfluidics can provide brand-new techniques for drug analysis, including medicine screening, active testing as well as the study of metabolic process. Microfluidic chip innovations, such as lab-on-a-chip innovation, three-dimensional (3D) cell society, organs-on-chip as well as bead methods, have actually all been created swiftly.

Keywords

Microfluidics; Lab on a chip; High efficiency; Cell culture

Introduction

Development of novel drugs and also new approaches for reliable delivery are appealing to improve therapy results by boosting bioavailability as well as specificity of the healing representative, while minimizing toxicity. Several traditional mass techniques to synthesize drug or gene shipment systems experience several downsides such as the demand to use a huge quantity of valuable drugs or chemicals, the generation of poly disperse fragments that influence the release profile, the limitation of generating service providers filled with numerous therapeutic representatives, and the problem related to localizing medicine distribution and also exploring the therapeutic/toxic results in vivo, which calls for numerous pets. Microfluidic modern technology has been established rapidly in recent decades and offers multitudinous application in life sciences.

Literature Review

The microfluidics change occurred because of the distinct advantages provided by system miniaturization, including the high analytical throughput, improved level of sensitivity, enhanced logical efficiency, accomplished parallelization via multiplexing, the capacity to deal with and also refine reduced reagent volumes as well as vastly minimized crucial footprints. Medication development involves numerous primary processes, such as drug exploration, preclinical tests, as well as clinical tests, to create a brand-new medication for the market. Drug analysis is prevalently made use of in all of these processes. However, this complex process still faces some obstacles from considerable problems such as time usage, low-throughput as well as cost. Microfluidics, as a miniaturization technology, can concurrently offer analytical effectiveness and also high-throughput capabilities, without the loss of accuracy and also automation. Throughout the process of medicine application, micro fluidics modern technology is not only an effective instrument for the rapid screening and evaluation of medication discovery yet likewise reduced expenses and also reagent usage by its miniaturized gadgets. The volume of the microfluidic chip device is very little as well as numerous features can be integrated on a chip of a number of centimetres.

Related Study

Production vulnerability and also efficiency of created drug/ gene service providers depend on microfluidic makers such as diffusion-based mixer, droplet generator, chaotic mixer, and automated microfluidic system. The microfluidic diffusion-based mixer is one of the most frequently used synthesizers. It is made up of several inlets and also one electrical outlet [1]. In this system, the reactions in between service provider products as well as particles are regulated by the network length as well as circulation price. To raise the diffusive limit location of the samples by at least 2 orders of size, incorporation of the herringbone pattern boosts the quick as well as reproducible generation of drug delivery systems. However, mixing methods that count on the diffusion between apart circulation streams under a continual flow procedure in the limit may result in large amounts of unreacted products, which may increase the cytotoxicity as well as reducing of the price of drug transportation. For this reason, bead generation strategies are an appealing alternate service that allows responses to happen within the beads separately. In this system, the response price and dimension, the overall quantity, and the proportion in between responded molecules in the micro channel can be controlled precisely while staying clear of contamination problems. Such platforms give new understandings right into biological processes and allow the reliable and also quick generation of unique pharmaceutical analysis. Microfluidic modern technology is being utilized to establish cost-efficient artificial insemination designs for lead compounds that can extra reliably anticipate the efficacy, toxicity and also pharmacokinetics of drug substances in human beings, along with for unique testing assays [2].

Micro fluidic devices are re-cognized as helpful not only for saving room and also scarce/expensive materials however likewise due to the fact that miniaturization offers numerous added supremacies. This innovation has actually ended up being a significantly encouraging tool for basic as well as used research study on medications. High-throughput methods are critically needed for the effective testing of pharmaceutically valuable lead substances. To determine reliable compounds for a particular biological process, the fast progression of high-throughput screening (HTS) allows parallel evaluations of thousands of reactions. The majority of the current HTS innovations include robotics for automated fluid as well as plate handling. Although the throughput has been increased tremendously by this automated modern technology contrasted to manual operations, the high costs associated with the instrumentation have actually restricted numerous researchers from carrying out HTS separately. Because of this, there is a solid desire to establish low-cost modern technologies that require decreased example and also reagent consumption. For that reason, the advantages of the micro-fluidics-based highthroughput drug screening system have actually gradually ended up being famous. Over the past few years, substantial progression has been attained in establishing mini fluidics based drug testing parts and also systems. Different types of microfluidic chips are used for medicine testing to raise the efficiency of testing and also lower costs. The following paragraphs checklist a number of common kinds of chip technologies [3-5].

Proposed System

The specific control of structure and circulation at the mini range permits the accurate modelling of body organ cells structures to be constructed at micro range. Organs-on-chips are microengineered biography mimetic systems that represent essential practical units of living human body organs. To date, functions of various organs and cells, such as the liver, kidney, lung as well as gut, have been replicated as in vitro designs. These systems can be made use of as inviter designs that permit simulation as well as pharmacological modulation of intricate biological processes. Furthermore, a body-on-a-chip, which integrates multi organ functions on a microfluidic tool, has actually also been proposed for anticipating body organ interactions. Cancer cells is a significant worldwide human health issue with an incompletely clarified pathogenesis; hence the study of cancer cells systems and also the discovery of reduced poisoning and also effective drug from natural substances are vital to the advancement of anticancer medicines. Any body organ chips are made use of in this area. This innovation provides novel approaches to resemble the in vivo tumour micro-environment in order to examine medication impacts [6-8].

Operation

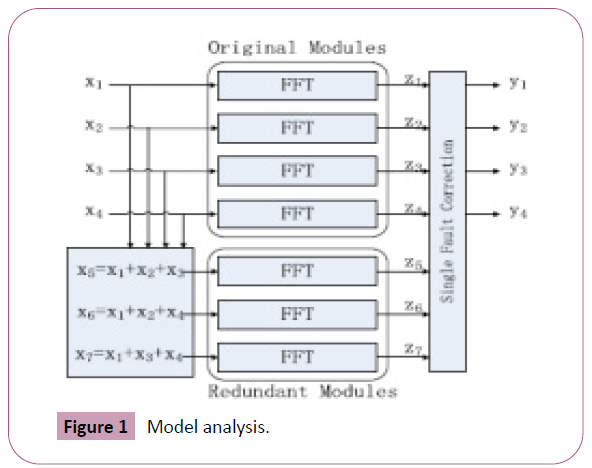

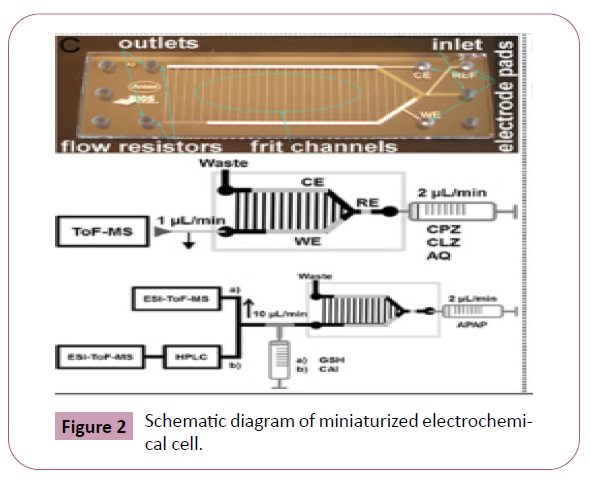

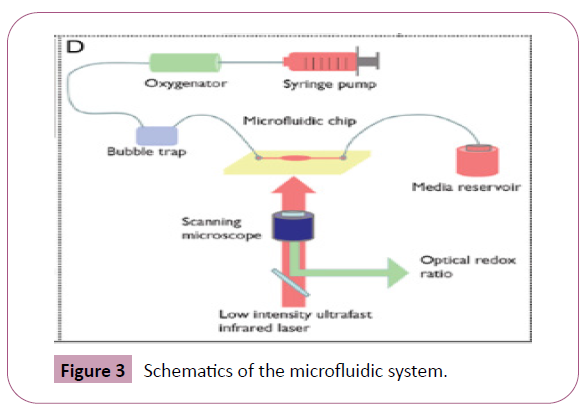

Along with the previously mentioned mainstream technologies, there are numerous various other modern technologies related to microfluidic chips for medicine testing, which expands the researchers' ideas. An excellent HTDS system has come to be the most crucial and also incorporated element of medication discovery in the majority of pharmaceutical and also several bio-technology sectors worldwide. Researchers utilize a lot of experimental systems to screen a variety of con-cent rations/ combinations to recognize a proper sensitizer and to discover efficient medicine combinations for condition treatment. It is feasible to evaluate different concentrations and mixes of medications via the application of open-access micro fluidic problem selection systems and also cell microarray chips [6-8]. The various styles of the chip can create different mixes and ranges of little society chambers (Figure 1). The consumption of cells as well as reagents is significantly lowered; the handling is done in a flexible as well as easy means and also the function of immediately screening intricate mixes is realized with further boosted gadgets. Concentration gradient generators can produce an exact gradient of fluid concentration, and some research study teams have actually used and combined these gadgets with microfluidic technologies to maximize HTDS systems. The microfluidic diffusive mixers in (Figure 2) can additionally recognize a fully automated HTDS: each diffusive mixer includes two integrated micro pumps linked to the media and the medicine storage tanks without the need for any type of extra devices to perfuse the remedy; this device minimizes medicine intake as well as does not require the constant generation of remedies. Along with the consideration of the high-throughput factor, price and also various intakes are likewise our emphasis. Typical drug testing efforts rely on using 96-well plates to evaluate the efficiency of various medication candidates' against vital biological targets. An effective droplet micro fluidics-based approach evaluated the dynamics of drug uptake, efflux and also cytotoxicity in drugsensitive as well as drug-resistant breast cancer cells. Pang et al. established an integrated microfluidic platform for the building of single-cell selections and also the analysis of medicine resistance. (Figure 3) reveals the design and also concept of the gadget. The effect of the biomechanical diversification of cells on their organic characteristics was examined. The results showed that the bio-mechanics of solitary glioblastoma cells had considerable implications for mobile medicine resistance.

Figure 1: Model analysis.

Discussion and Conclusion

Exceptional growths in the construction of microfluidic devices have taken place throughout recent years, either to generate reliable medication distribution systems or to boost testing techniques. Micro- or nanoparticles created by microfluidic systems are consistent in dimension as well as morphology, envelop even more representatives, and also display slower drug launch prices than some created by bulk techniques. The physical as well as chemical features of medicine providers can be customized by managing the circulation rates of liquid remedies, make-up, temperature, pH, as well as various other ecological variables. The main challenge encountering any type of medication shipment system is how to achieve lasting stability in the shelf as well as in bodily fluids under biological problems. The brandnew discovery technology and distinct layout allow researchers to quickly spot trace amounts of drugs in biological samples, as well as to spot metabolic procedures and also metabolites of medicines. Compared with traditional whole animal experiments and in vitro screening approaches, generally, mini fluidic chips provide obvious benefits. Nonetheless, the complicated layout of microfluidic chips, the stable attachment and integration of various functional organ chips, and the adjustment as well as development of various culture problems in a range of cell cocultures call for further optimization as well as experimentation. The problems of molecular absorption, mass transfer, and bubble generation inside the devices necessitate immediate options. Excellent functional stability and also repeat-ability are vital for the promo of the method. On top of that, the high price and made complex preparation and also procedure procedures are likewise concerns needing focus. If easier, straightforward as well as lowcost gadgets can be created, the microfluidic chip promises to play a higher function in pharmaceutical analysis.

References

- Kodzius R, Xiao K, Wu J, Yi X, Gong X, et al. (2012) Inhibitory result of normal microfluidic items on PCR outcome. Sens Actuators B Chem 161: 349-358.

- Park J, Li J, Han A (2010) Micro-macro hybrid soft-lithography master (MMHSM) fabrication for lab-on-a-chip applications. Biomedical Microdevices 12: 345-351.

- Del Campo A, Arzt E (2011) Generating micro-and nano patterns on polymeric materials. John Wiley & Sons.

- Lee W, Jambovane S, Kim D, Hong J (2009) Predictive model on mini droplet generation through mechanical cutting. Microfluid Nanofluid p. 431-438.

- Nunes P, Ohlsson P, Ordeig O, Kutter J (2010) Cyclic olefin polymers: Appearing items for lab-on-a-chip applications. Microfluid Nanofluid p. 145-161.

- Ren K, Dai W, Zhou J, Su J, Wu H (2011) Whole-Teflon microfluidic chips. USA. Proc Natl Acad Sci 8162-8166.

- Kim J, Kang M, Jensen E, Mathies R (2012) Microvalves as well as pumps for microfluidic control. Anal Chem 84: 2067-2071.

- Champion J, Katare Y, Mitragotri S (2007) Fragment type: A brand-new format criterion for mini- as well as nanoscale medication delivery provider. J Control Release 121: 3-9.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences