ISSN : 0976-8505

Der Chemica Sinica

Abstract

Study of high emissivity coating of ceramic material for energy conservation

Present paper reports a study on the development of high emissivity coating materials with certain properties which essentially increase the efficiency of heater system. In this study, a high emissivity .Coatings is applied on refractory substrate. The Coating materials are capable of absorbing and reradiating thermal energy. The emissivity coating material is applied at the outer surface of the ceramic heater where the heating elements are inserted in the groove. The objective is to direct the radiation heat evolved during electrical heating glowed upwards so as to increase faster heating rates. Here, an attempt is made to study the effect of suitable coating with higher emissivity on the refractory substrate in the laboratory. The objective is to find out effectiveness of the emissivity coatings on the consumption of electricity units in heater applications. The coatings materials are consisting of various combinations of Zirconium, Silicon Carbide, Chromium, suitable binder, additives and some amount of clay. The binder is formulated to adjust desired consistency and drying characteristics of paint. The coating material is applied as usual methods such as spraying whereby a uniform thin layer is achieved. To increase the solid content, the coating is applied no. of times to study dependency of thickness. Some coating was also made on the ceramic heater by brushing etc. A fixed quantity of water has been subjected to boiling and time is noted when the first boiling starts. This study has demonstrated the heating time for the coated and uncoated heater. The resultant time of heating has been reduced and the unit obtained through based on calculation showed a reduction in energy. Thus, suitable coatings developed in the laboratory showed a result oriented practical findings which could be useful in various heater/furnace applications whereby such coating reradiate the heat absorbed on the surface and thus saves energy. Also, it is shown that with the thickness the emissivity coating, increases with the increase in temperature in this experiment carried out in the laboratory, an average of energy saving up to 11-15% has been observed on the coated electric heater system

Author(s): Dipen V.Chauhan1, S. N. Misra2 and R. N. Shukla3

Abstract | PDF

Share This Article

Google Scholar citation report

Citations : 6019

Der Chemica Sinica received 6019 citations as per Google Scholar report

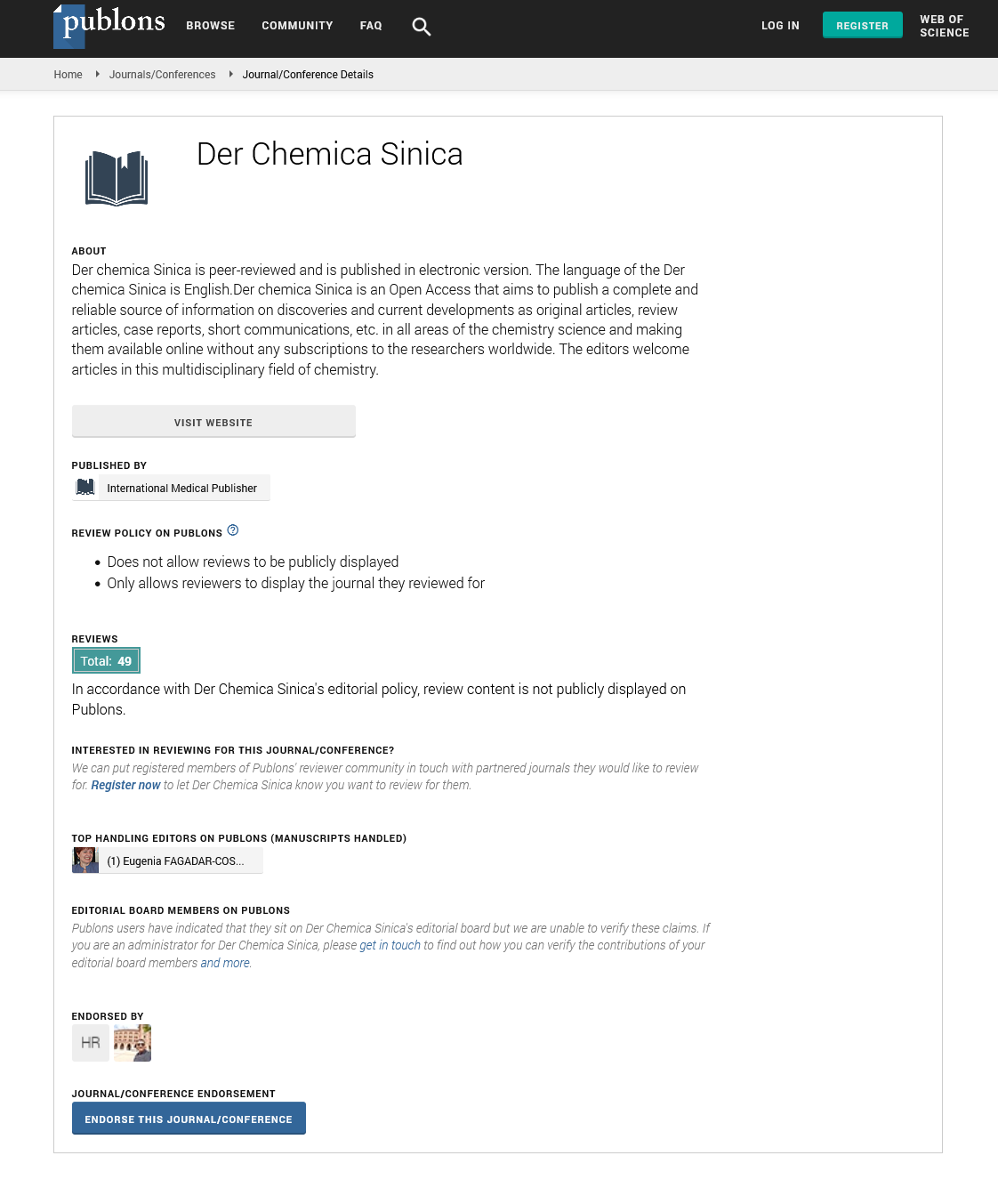

Der Chemica Sinica peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- China National Knowledge Infrastructure (CNKI)

- Directory of Research Journal Indexing (DRJI)

- Publons

- MIAR

- International Committee of Medical Journal Editors (ICMJE)

- Serials Union Catalogue (SUNCAT)

- Geneva Foundation for Medical Education and Research

- Secret Search Engine Labs

- Euro Pub

- CAS (Chemical Abstracting Services)

- University of Barcelona

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences