ISSN : 2393-8854

Global Journal of Research and Review

Assessment of Workplace and Health Hazards in Steel Industry a Review Article

Aatika Murtaza*

Department of Environmental Science, Institute of Environmental Science and Engineering (IESE), National University of Science and Technology (NUST) H-12, Islamabad, Pakistan

- *Corresponding Author:

- Aatika Murtaza

Department of Environmental Science, Institute of Environmental Science and Engineering (IESE), National University of Science and Technology (NUST) H-12, Islamabad, Pakistan

E-mail:maatika231999@gmail.com

Received date: January 23, 2024, Manuscript No. IPGJRR-24-18578; Editor assigned date: January 25, 2024, PreQC No. IPGJRR-24-18578 (PQ); Reviewed date: February 08, 2024, QC No. IPGJRR-24-18578; Revised date: January 10, 2025, Manuscript No. IPGJRR-24-18578 (R); Published date: January 17, 2025, DOI: 10.36648/2393-8854.12.3.121

Citation: Murtaza A (2025) Assessment of Workplace and Health Hazards in Steel Industry a Review Article. Glob J Res Rev Vol:12 No:1

Abstract

Steel as the world’s most recycled material have its great influence in everyday life. Globally, over 6 million people are working in steel industry. Steel industry provide raw materials to many industries such as energy, construction, automotive, transportation, infrastructure, packaging and machinery. Besides, its major role in industrialization, steel production operations and handling possess a number of hazards for workers in steel industry. Because of lack of safety measures and continuous working in same environment there are several kind of workplace hazards that are found in workplace environment such as physical hazards of slips, trips, falls, overhead cranes, high temperature in working environment and manual handling of heavy objects. The respective health impacts caused by workplace hazards include respiratory issues, heat stress impacts, noise related problems, lungs infections, and number of injuries to fingers, hands and to other body parts. By implementing occupational health and safety regulations and by actively using personnel protective equipment’s any kind of accident can be handled efficiently.

Keywords

Steel industry; Workplace hazards; Health hazards; Occupational health; Work-related injuries; Respiratory symptoms; Occupational heat stress; Industrial fatalities

Introduction

Being a crucial component for modern civilization, steel has a strong cultural and societal impacts. Across the globe, it seems that the steel industry is among those that influences the growth of national economies to a far higher extend than is generally acknowledged [1]. This is due to the fact that the steel industry contributes significantly to economic growth of certain area since it supplies raw materials to several industries, including the automobiles, consumer durables, infrastructure, railways, and aircraft building sectors [2]. Steel’s evolution dates back 4,000 years, to the start of the iron age. Bronze was gradually replaced by iron in tools and weapons due to its superior strength and hardness. Iron’s characteristics were widely known by the 17th century, but as Europe became increasingly urbanized, a structural metal with greater versatility was needed. Besides, metallurgists had an economic incentive to discover a solution to iron’s brittleness and wasteful manufacturing procedures during the 19th century due to the amount of iron being used by developing railroads. The greatest significant development in steel history occurred in 1856 when Henry Bessemer discovered a practical method of using oxygen to lower the carbon content of iron, having given rise to the modern steel industry and today, according to the world steel association across the worldwide, the steel demand witness 1.8% increase in 2023 and will further increase to 1.9% in 2024 [3]. The manufacturing of steel is done by using two different methods, Basic Oxygen Process (BOP), also referred as the blast furnace process, and Electric Arc Furnace (EAF) process [4]. Besides, its major role in industrialization, the process of making steel is intricate and difficult, including workers exposure to extreme heat, handling of heavy equipment, noxious chemicals, and other environmental and physical risks at workplace. There are numerous likely health and safety hazards for steelworkers, including as cuts, burns, breathing issues, hearing loss due to high level of noise and many more other impacts that has significant human cost and severely affects the economic potential and productivity of the certain area [5]. The main challenges of any sector for improving the performance of its employees are safety and health at workplace, particularly in developing countries. The primary causes of accidents in the industry are poorly designed workplace structures, adverse climatic conditions and inadequate management. This can result in harm to the workers, poor health for employees, and reduced productivity and quality of work [6]. Occupational health and safety is a prerequisite to ensure that worker’s welfare is protected, and supported in a safe and efficient way thus helping business owners accomplish the core goals of their social obligations. It’s an invincible pattern to support economic growth and reinforce the advantages of business, representatives, and natural conditions [7]. With the passage of time, in light of increasing globalization, many firms become active in monitoring environmental health and safety conditions along with unjust labor practices in different industrial operations mainly in developing countries. Incorporating risk management into different industrial operations may help in reducing accidents and improves company’s reputation while enhancing workers performance, economic advantages and financial gains [8].

Literature Review

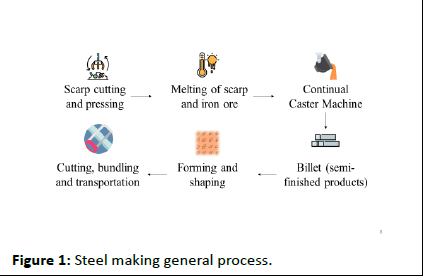

The manufacturing of steel starts with cutting and pressing of scarp. After that scarp along with iron ore are heated in a furnace to temperature above 1500°C. The red-hot molten metal is then added into continual caster machine that converts it into solidified semi-finished products known as billets. Successive changes of billets takes place through rolling mills. In consequence, final product of steel is composed of fine variety which is transported to end users after cutting and bundling (Figure 1) [9].

Figure 1: Steel making general process.

The primary processes involved in steel production include Blast Furnace/Basic Oxygen Furnace (BF-BOF), Direct Reduction/ Electric Arc Furnace (DRI-EAF), Smelting Reduction/Basic Oxygen Furnace (SR-BOF) and melting of scarp in Electric Arc Furnace (EAF). The most significant method of producing steel is the BFBOF method in which coal, and coke used as primary energy source and this route accounts for around 71.5% global steel output. Approximately 28.2% of world steel production comes from the recycling and melting of steel scarp in EAF, which is the second most prominent steel production process after BF-BOF. Only 0.4% of steel is produced around the globe by using some other approaches which basically involve burning of coal to reduce iron ores without agglomeration.

Workplace hazards in steel industry

Steel industry is known as the most challenging for being one of the riskiest and most difficult place to work. Workers deals with several mishaps and other issues that jeopardize their safety, like as vibrations, loud noises, operating machinery without safety guards that increase risks of injury, and several additional circumstances [10]. The nature of working environment of steel industry exposes their workers to several hazardous risks of infections and non-fatal injuries [11]. Workplace hazards in steel industry include work design hazards that results in work-related musculoskeletal disorders, prolong standing and repetitive motions, physical hazards such as noise, heat stress, lighting and vibration, slips, trips because of messy walkways, falls from height, overhead cranes and handling of heavy load manually such as metallic objects and steel blocks [12].

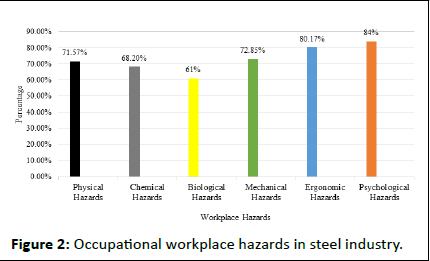

A study conducted in Bhusan Power and Steel Limited, Sambalpur Odisha state in India by using descriptive survey design with quantitative approach to identify the risks among workers exposed to occupational health hazards associated with workplace design hazards. By purposive sampling methodology, 215 workers were selected and structured interview was used to collect data from workers. The results of below figure indicates that the 84% of respondents from the total 215 were exposed to psychological hazards with mean percentages of 80.17%, 72.85%, 71.57%, 68.20% and 61% for ergonomic, mechanical, physical, chemical and biological hazards. The physical hazards caused by excessive noise, eating in unhygienic conditions lead to biological hazards, and mechanical hazards because of working below overhead travelling crane (Figure 2) [13].

Figure 2: Occupational workplace hazards in steel industry.

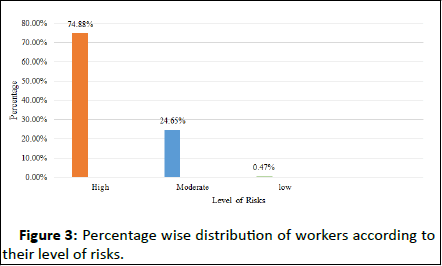

The figure displays the percentage wise distribution of workers at the steel industry based on their risk tolerance. According to the static, the largest proportion of workers (74.88%) were at high risk, while 24.65% of workers were in moderate risk category. A further 0.47% of workers belonged to low risk level. The high percentage of high level risk was there as workers were working with hands above their shoulder height (Figure 3).

Figure 3: Percentage wise distribution of workers according to their level of risks.

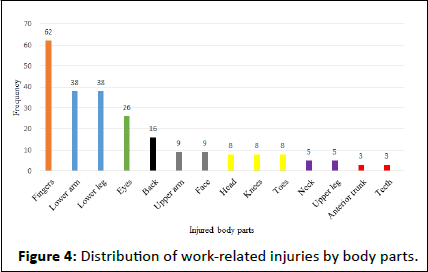

From August to September 2010, four iron and steel industries workers in Addis Ababa, the capital city of Ethiopia were selected for institution based cross-sectional survey. Ethiopia iron and steel (1959), Akaki metal products (1964), Kaliti metal products (1968), and Akaki spare parts and hands tools (1989) are the four government controlled industries that were chosen for study purpose. Worker’s behavioral traits, sociodemographic information, and work-related injuries in the last 12 months were collected by using a pretested and structured questionnaire. The injured body parts and types of injuries for identified by observations. In addition to evaluation, medical reports, occupational health and safety plans, and programs were examined, and an observational checklist was utilized to evaluate the workplace hazards and environmental conditions. Total 444 workers participated in the survey, out of which 33.3% of the workers had experienced an injury at work within the previous year. In a single year, 73. 6% of workers injured once, 18.9% twice, and 7.4% of workers injured more than three times. As shown in below figure fingers, lower arms, legs, and eyes were the most often afflicted body parts (Figure 4) [14].

Figure 4: Distribution of work-related injuries by body parts.

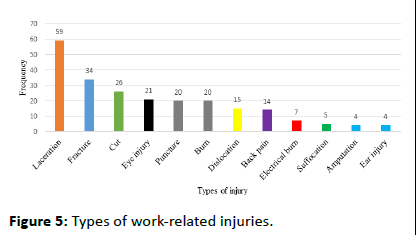

According to the data shown below in figure, laceration and fracture were the most prevalent injury types. The most frequent causes of injuries were falling or splitting things (16.4%), being struck by falling objects (13.7%), being hit by machinery (12.6%), and using hand tools and instruments (Figure 5).

Figure 5: Types of work-related injuries.

Health problems faced by workers in steel industry

Around the globe, workers spend at least a third part of their lives at work, and the revenue that they pay in income taxes supports the material and economic foundation of society. Unfortunately, the accidents at workplace cost several hundred hours of productivity each year. Global estimates show that over 2 million deaths, around 337 million injuries and illness are linked to work-related causes of death each year. Worldwide, industrial workers’ fatalities and illnesses are mostly caused by occupational health risks. Any type of health effects caused by different workplace hazards can affects the industrial workers in many ways from physical damage to death [15]. The Table 1 shows the different categories of workplace impacts of steel industry with their associated health problems [16-19].

| S. no | Category | Health problems |

| 1 | Work design related impacts | Work-related musculoskeletal disorders, low back pain, shoulder, and neck pain, tendonitis and carpal tunnel syndrome. |

| 2 | Heat related impacts | Excessive sweating, muscle cramps, dizziness/fainting, exhaustion, headaches, excessive thirst, heat rashes, fatigue, body heat and aches. |

| 3 | Noise related impacts | Increased anger, ear ache, ear discharge, headache, hypertension, and depression, temporary and permanent hearing loss. |

| 4 | Respiratory problems | Lung infections, shortness of breath, coughing, asthma, tuberculosis, phlegm, cough with phlegm, wheezing, chest tightness, throat and nasal infections. |

Table 1: Categories of workplace related health impacts.

Discussion

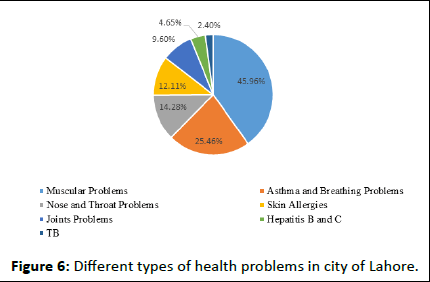

To evaluate the general working conditions of workers, a study of more than two hundred iron and steel industrial units in and around the Lahore city was conducted. The unit’s structural design, the kind of product, production capacity, number of employees, the number and duration of shifts, noise level and temperature were considered to determine how bad the working conditions were in these industrial units. In order to evaluate the health conditions and associated risks, data was collected from around 300 employees across 18 units. The data indicated that air temperature varied between 40°C-49°C and at certain points, the noise intensity exceeded 80 dB, even exceeding 110 dB. Blood pressure, body temperature and Body Mass Index (BMI) all exhibited tendencies below average. In accordance with the health conditions the below figure showed that there were 45.96% muscle problems, 25.46% asthma and breathing issues, 14.28% nose and throat problems, 12.11% skin allergies, and 9.6% joint issues along with some other disorders. Hepatitis B and C were discovered in 4.65% of patients. 2.4% of workers had TB with varying degree of treatment. All ranges of workplace injuries were found in 26.4% workers (Figure 6) [20].

Figure 6: Different types of health problems in city of Lahore.

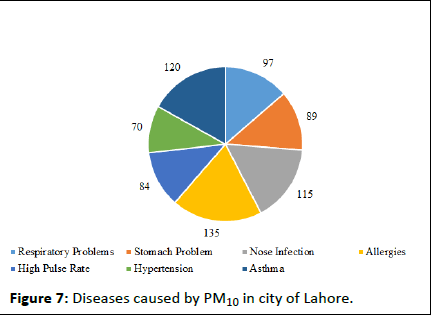

Another study from Lahore, Pakistan focused on relationship between industrial (iron and steel) air pollution and its impacts on human health identified that the emissions of industrial pollutants were above the threshold limit in Lahore. For the study total thirty-six iron and steel re-rolling industries were selected and one hundred and fifty respondents were taken from nearby residential area by random sampling method. The below figure indicates that among 150 individuals, 70, 97, 115 and 120 persons had low-level asthma, hypertension, respiratory issues and nasal infections caused by PM10 concentration. The listed disorders were frequently observed in the vicinity of the research area owing to the impacts of varying level of PM10 on human health (Figure 7) [21].

Figure 7: Diseases caused by PM10 in city of Lahore.

In Turkey’s Karabuk city, near the black sea, a study was conducted. 2600 workers were employed by plant working eight hours a day, five days a week, in three shifts. For survey, closing questions regarding air quality and humidity that are related to thermal working conditions were developed. In addition, there were concerns about how work was completed, the amount of water consumed daily, rest periods, and the degree of physical activities during working hours. The questionnaire also contained an open-ended question about any changes that the staff would want. According to survey data, a majority of workers experienced heat exhaustion during the hot summer months, with temperature ranging from 34 to 40.9°C. From the respondents, 44% claimed to be extremely warm, 52% reported feeling hot, and 4% felt dry. The most prevalent condition in chosen occupations was heat rashes, which often goes away when the workers enters the cold sitting area. The effects of air pollution and occupational heat stress on health and social issues were stated by 30% workers. Some of the complaints they made were of being too exhausted to spend time with families after work, weakness, sweating excessively, headaches, hearing loss, and lack of ventilation. Before the launch break, over two third of workers said that the first half of their shift was severe. Approximately 30% less efficiency was achieved in the remaining hours. A two-hour increase in performance was observed by 19% of respondents after starting work, while 17% reported high activity levels over the whole workday [22].

Conclusion

On the basis of available information from literature review of different studies it is concluded as, besides that steel industry having strong societal and industrial influence, the working conditions in steel industry are challenging as it has been historically and continues to be a dangerous industry. Steel making processes are hazardous in many ways that cause severe kind of injuries that can even lead to death of workers from. Many labor oriented industries have traditionally been shifted towards automation and mechanization systems, but still there is a lack of broad knowledge on the risks related to occupational safety, health and the environment. In a country, like Pakistan, industries are still far behind in putting occupational health and safety systems into places. By adopting precautionary measures efficiently every accident can be prevented and mitigated in proper way.

Recommendations

For an improved occupational health and safety management system to reduce workplace accidents and to improve health conditions of workers in steel industry, here are some recommendations;

• There should be occupational health and safety orientations on regular intervals to ensure that new workers are aware about their working conditions, possible risks, and hazards, and about their preventive measures.

• Machine guards and protective barriers should be used to prevent ultimate accidents and injuries of workers.

• Ensure proper ventilation and supply sufficient fresh air to workers at hot places and shifts their duties after few times in other departments.

• Install heat insulating devices to reduce the temperature at workplace especially near burning furnace.

• Use appropriate sign boards for hazardous areas in a way that a layman can understand that signs easily if mistakenly enter in such area.

• Provide proper training to workers who work with chemicals to avoid any kind of chemical explosion.

• Surfaces, structures and walkways should be maintaining and clean on regular basis to prevent physical hazards such as slips and trips.

• Provide necessary equipment’s such as noise controlling device ear plugs to workers who are working in high noisy area.

• Manual handling of heavy objects more than 15 kg should be banned and reduce manual handling at possible level.

• Ensure active use of PPEs and take strict actions to implement safety guidelines.

• Implement fall protective measurements in industrial area where there is risk of fall especially from heights.

• Conduct both internal and external regular safety audits and inspections.

References

- Mousa E, Wang C, Riesbeck J, Larsson M (2016) Biomass applications in iron and steel industry: An overview of challenges and opportunities. Renew Sustain Energy Rev 65:1247–1266

- Yazar H, Erdogdu M (2023) Industrial Policy in the Development of the Iron and Steel Industry in Several Countries. Industrial Policy 3:4-11

- Vinay A (2023) Global steel demand likely to rise 1.8% in 2023, 1.9% in 2024: worldsteel.

- Reed B (2023) The Steel Manufacturing Process-How is Steel Made?

- Correa P (2023) Working together to ensure the health and safety of workers in an evolving steel industry.

- Cunningham TR, Galloway-Williams N, Geller ES (2010) Protecting the planet and its people: how do interventions to promote environmental sustainability and occupational safety and health overlap? J Saftey Res 41:407-416

[Crossref] [Google Scholar] [PubMed]

- Yu W (2009) Occupational Health and Safety in China calls for CSRA Case study of China CDC and GE Foundation Project. Social Responsibility Research Network 2-7

- O’Toole M (2002) The relationship between employees’ perceptions of safety and organizational culture. J Saf Res 33:231-243.

[Crossref] [Google Scholar] [PubMed]

- Poudel RC, Sakaguchi T, Shimizu Y (2013) A Selective Approach on Data Based Quality Prediction for Quenched and Tempered Steel Reinforcement Bars. J Chemi Eng Jpn 46:294-301

- Umugwaneza C, Nkechi IE, Mugabe JB (2019) Effect of Workplace Safety and Health Practices on Employee Commitment and Performance in Steel Manufacturing Companies in Rwanda. Eur J Bus Manag Res 4

- Dehabadi PK, Arani MH, Akbari H, Shamsi MS, Karamali F (2023) Risk Assessment of Reheating Furnace by Failure Modes and Effect Analysis Method in Steel Complexes. Arch Trauma Res 12:27-33

- Amjad H, Khan Z, Ghafar S (2010) A Case Study on OHS Practices in Steel ReRolling Mill, Islamabad. In 7th National Seminar on Occupational Health, Safety and Environment, National University of Science and Technology. pp. 1-2

- Choudhury C, Jena N, Dash MB (2020) Identification of Risks among Workers Exposed to Occupational Health Hazards in view of Developing an Information Booklet on Awareness and its Prevention in a Selected Steel Industry of Odisha. J Comm Soc Health Nursing 2:39-45

- Kifle M, Engdaw D, Alemu K, Sharma HR, Amsalu S, et al. (2013) Work related injuries and associated risk factors among iron and steel industries workers in Addis Ababa, Ethiopia. Saf Sci 63:211-216

- Pillay KR (2014). The costs of construction accidents. LAP LAMBERT Academic Publishing.

- Singh J, Suryawanshi V, Patel P (2014) Hazards Analysis & Evaluation in Steel Processing Plant. Int J Eng Res Technol 3:628-631

- Krishnamurthy M, Ramalingam P, Perumal K, Kamalakannan LP, Chinnadurai J, et al. (2016) Occupational Heat Stress Impacts on Health and Productivity in a Steel Industry in Southern India. Safe Health Work 8:99-104

[Crossref] [Google Scholar] [PubMed]

- Liaqut A, Younes I, Sadaf R (2017) Spatial Distribution of Noise Released from Iron and Steel Industry and their Effects on Human Health in the Lahore City, Pakistan. J Basic Appl Sci 13:117-122.

- Mozaffari S, Heibati B, Jaakkola MS, Lajunen TK, Kalteh S, et al. (2023) Effects of occupational exposures on respiratory health in steel factory workers. Front Public Health 11:1082874

[Crossref] [Google Scholar] [PubMed]

- Malik HJ (2010) Preliminary Survey to assess the Health status of Iron and Steel industry workers. Pak J Sci 62

- Younes I, Liaqut A, Sadaf R (2020) Consequences of Released Air Pollutants from Iron and Steel Industry on Human Health in Lahore, Pakistan. Pak Acad Sci 57:59-75

- Karim Fahed A, Ozkaymak M, Ahmed S (2018) Impacts of heat exposure on workers’ health and performance at steel plant in Turkey. Eng Sci Technol Int J 21:745-752

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences