A Preliminary Evaluation of a Hydro-cast Trans-femoral Socket, a Proof of Concept

Arjan Buis1*, Mojtaba Kamyab2, Susan Hillman3, Kevin Murray1 and Anthony McGarry1

1Department of Biomedical Engineering, University of Strathclyde, Glasgow, Scotland, UK

2Department of Orthotics and Prosthetics, Tehran University of Medical Sciences, Tehran

3Astley Ainslie Hospital, Anderson Gait Analysis Laboratory, Edinburgh, Scotland, UK

- *Corresponding Author:

- Buis A

Department of Biomedical Engineering

University of Strathclyde, Glasgow, Scotland, UK

Tel: 0044 (0)141 548 4716

E-mail: arjan.buis@strath.ac.uk

Received date: November 09, 2016; Accepted date: April 18, 2017; Published date: April 24, 2017

Citation: Buis A, Kamyab M, Hillman S, Murray K, McGarry A (2017) A preliminary evaluation of a hydro-cast trans-femoral socket, a proof of concept. Pro Ort Open J 1: 7.

Copyright: © 2017 Buis A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

This study reports on a research project that has utilised, for the first time, a Hydro-casting (HC) technique to create a prosthetic socket for a person with trans-femoral amputation. Outcome measurements of the HC socket were compared with a socket and prosthesis produced by conventional ischial containment (IC) technique. Comparisons were based on differences in (a) stump-socket interface pressures during gait, (b) whole body gait kinetics and kinematics (c) femoral movement within the stump tissues relative to the socket during gait. These observations provided a snapshot of the biomechanical environment of the stump and socket interface and assess the feasibility of using these outcome measurements to highlight differences between the two socket designs. This study demonstrated that it is feasible to use the HC approach to produce a prosthesis that is acceptable to both user and clinician. Results showed similarities between interface pressures, kinetic and kinematic data for both socket designs. The use of ultrasound to detect femoral motion identified that the conventional design paradigm, claiming to stabilise the motion of the femur, may not actually achieve this goal. Additional research is required with larger population of people with a trans-femoral amputation to assess the long term impact of this novel approach.

Keywords

Prosthetics; Amputation; X-ray; Abduction/ Adduction; Flexion/Extension

Abbreviations/Definitions

Prosthesis, prosthetic device: externally applied device used to replace wholly, or in part, an absent or deficient limb segment

Trans-tibial: Amputation through the limb below the knee and transecting both the tibia and fibula.

Trans-femoral: Amputation performed at a level above the knee joint.

Hydro-casting (HC): A technique of applying controlled pressure to the tissues of an amputation stump and casting material to fashion a socket design shape using quasihydrostatic pressure.

Ischial Containment (IC): A design of trans-femoral prosthesis socket employing lateral socket wall pressure and enclosure of the ischium to stabilise the movement of the femur during gait and thereby enhance usability.

Introduction

In contemporary prosthetic practice there is clinical consensus that the ‘quality’ of the socket providing the coupling between the tissues of the residual limb and the structure of the prosthesis is vital to the overall success of the prosthetic replacement [1-10]. However, there is limited evidence available about what actually determines the quality of fit and few reliable measurements have been taken of the biomechanical environment that could constitute a high quality result. This is perhaps not surprising as the stump socket interface brings together engineered materials, formed into a complex shape, with living tissue that has non-linear, time dependent and highly individual mechanical properties [11,12].

Trans-femoral amputation accounts for over 40% of all new amputations in the UK [13]. The Ischial Containment (IC) socket design is advocated at this level. The fundamental concept of the IC design is that greater control of femoral abduction during prosthetic mid stance phase, (and hence improved function), can be obtained by a particular shaping of the socket that “locks” around the ischium and loads the lateral aspect of the femur to effectively stabilise it [14-16]. Ischial containment sockets have however, continually evolved since their inception and a definitive design has not yet been established.

State of the art IC prosthetic sockets are designed and hand crafted on a bespoke basis. Procedures are highly individual, based on the tacit knowledge of a prosthetist and strongly influenced by personal experience, skill and beliefs [12]. If the socket design process is inconsistent this will also cause challenges in positioning the socket appropriately for ambulation (alignment) [17]. Without doubt, failure to create a repeatable standardised socket design will compromise prosthetic rehabilitation [8,18].

The creation of a socket through controlled pressure-casting has been advocated in many publications and is now used widely in trans-tibial, but not in trans-femoral prosthetics [19,20]. Pressure casting, using water as a pressurising medium, has been shown to be more repeatable [21], and reduce errors by the prosthetist that may occur during plaster cast modification [18]. Klasson and Buis [12], believed that improved function and less tissue stress in weight bearing would be achieved using Hydro-Casting (HC). Furthermore, they stated that traditional plaster room modification could be eliminated using this technique. Kristinsson [14] argued that the most effective socket should rely on a hydrostatic principle for weight transfer and that through application of a controlled pressurised casting technique a ‘near’ hydrostatic equilibrium point could be achieved. A socket which is of good fit, is considered to be one that reaches equilibrium with little vertical movement i.e. pistoning. To reduce the flow of all soft tissue structures, the socket should be shaped under a uniform pressure condition. In principle, when the skeleton attempts to translate into the socket, the tissues are therefore ideally positioned, and the socket shaped such that vertical movement is minimised.

Pressure casting deforms the soft tissue, under full load, such that hypothetically the stiffest path principle is achieved and internal shear stresses are minimized [12]. This is thought to be advantageous as the purpose of the socket is to provide a mechanical connection between skeleton and socket, utilizing the soft tissue as interdependent coupling elements. It is also expected that the stiffer this coupling, the more stability is realised, and therefore improved control of the prosthesis may be achieved.

The aim of this study is to assess the feasibility of shape capture of the trans-femoral residual limb shape using a HC technique, and to investigate the dynamic mechanical environment at the stump-socket interface and within the deeper structures of the stump. The overall impact of this approach on the gait of a person with trans-femoral amputation will also be examined. Outcomes from the novel HC technique will be compared with a socket and prosthesis produced by the established conventional ischial containment hand-casting technique.

Methodology

A 36 year old female volunteer from a Scottish based charitable prosthetic user support organisation, the Murray foundation, was recruited to this study. She had undergone a TF amputation in 1992 as a result of a giant cell tumor in the right tibia. Her current prescription which had not changed for over 10 years, included a flexible ischial containment socket with seal-in liner and a one –way valve, Otto Bock C-leg and dynamic plus foot. Ethical approval was granted by the Ethics Committee of the University of Strathclyde.

A crossover study design allowed direct comparison between the two interventions. However, it was not realistic to adopt a double-blind test as the socket design concepts were considerably different in human/device interaction and socket brim levels compromising unbiased user feedback. Two prosthetic sockets were manufactured. Both used the same silicone liner with pin and shuttle lock suspension and utilised the same knee and foot components. An identical copy of the existing IC design of socket was made and a transparent acrylic plastic socket manufactured to replace the socket of the existing prosthesis, with the aim to maintain component characteristics.

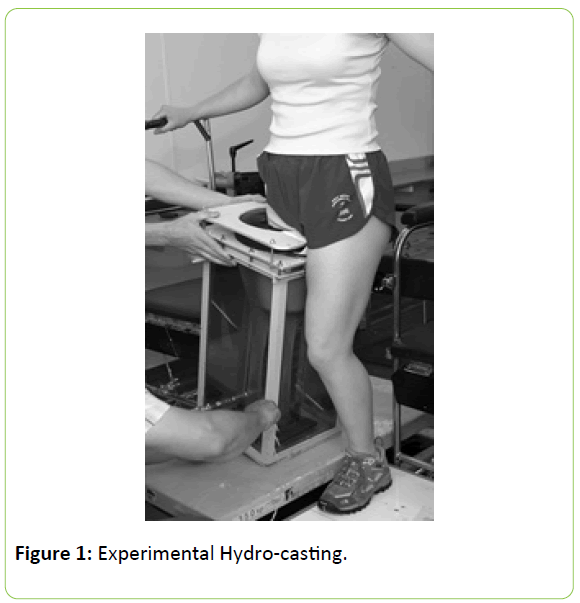

Additionally, a HC socket was manufactured (Figure 1). The experimental HC device consisted of an open top tank with an internal thin sleeve fixed at the proximal brim and was secured to the bottom of the tank. This created a sealed water tank with a collapsible tunnel, which acted as a barrier between the loading medium (water) and cast limb. Additionally, the tunnel design allowed the soft tissue to be stretched distally (slack elimination) by means of a lanyard threaded through the hollow bolt at the distal end of the tank.

A silicone interface liner was applied to the residual limb and a lanyard was attached to the distal adaptor of the liner and threaded through the flexible tunnel and hollow bolt previously described. Plaster of Paris (POP) bandage was loosely applied covering the whole residual limb. No attempt was made by the prosthetist to smooth or shape the plaster once applied. The final bandage applied was cut in two, and the remaining half used as a curing indicator. Immediately after application of the bandage, the limb was fully inserted into the tank. The entry to the tank had a flexible rubber template which acted as a sealing mechanism between limb and latex sleeve, preventing “ballooning” of the sleeve when pressurized.

Subsequently, the tank was filled with water until the patient was able to transfer full body weight to the amputated site. This meant that the soft tissues were fully loaded by a uniform pressure induced by the subject’s own body weight. Slack elimination was achieved by the application of a load to the soft tissue until no more visible elongation took place (typically between 20 and 30 Newton). The subject remained in situ until the POP cured, (approximately 4 minutes). No modifications were performed on the positive plaster model and a transparent plastic check socket was manufactured. The socket was placed on the same components that were used for the IC socket investigation. Since no known alignment criteria were available for this socket design the socket was dynamically aligned until the user and two clinicians were satisfied.

Outcomes for comparison were based on differences in:

• Dynamic stump-socket interface pressures during gait,

• Motion analysis (kinetics and kinematics) and

• Femoral movement within the stump tissues relative to the socket during gait.

These observations provide an insight of the biomechanical environment of the stump and socket interface and highlight any differences between the two socket designs.

Dynamic residual limb-socket interface pressures during gait

The pressure measurement system selected to monitor and record the interface pressure between the residual limb and prosthetic socket was a validated 6-channel F-Scan system™ (Tekscan, Boston, MA, USA). The authors were aware of the limitations of the pressure measurement system employed [22-24]. It is commonly accepted that the advantages of the Tekscan™ transducers are thickness, size, sensitivity, and resolution and frequency response. Disadvantages such as hysteresis, drift and temperature sensitivity have also been reported [23-27]. However, by adopting a strict protocol to precondition, equilibrate and calibrate the sensor arrays in situ before use, it was possible to minimize the variation and inaccuracy of data recordings [22]. Four channels were designated to the prosthetic socket (sensor array type 9811. The socket transducer arrays were glued inside each of the transparent check sockets according a predetermined reference grid, allowing over 80% surface coverage.

Gait kinetics and kinematics

Introduction

A state-of-the-art 3D Vicon™ motion capture system, equipped with twelve infra-red cameras and four Kistler™ force platforms were used to collect comparative full body kinematic (motion) and kinetic (force and acceleration) of upper and lower body gait data from the subject. This will allow any potential compensatory gait effects (E.g. limping and gapping) of each socket concept to be examined in detail.

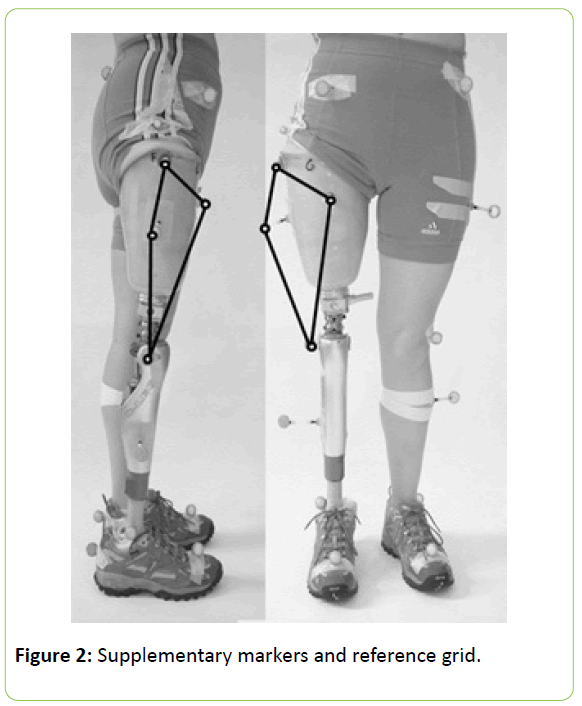

The Vicon Plug-in-Gait marker placement protocol was used which allowed the detailed examination of the effect of each socket philosophy on gait. In addition, supplementary markers were placed on the socket (Figure 2) with the aim to establish an independent reference grid. This configuration, in theory, would allow possible socket rotation, gapping and pistoning relative to the pelvis markers to be monitored.

Kinematic and kinetic data were collected as the subject walked along the laboratory walkway. Only trials in which the subject made a clean force platform strike with at least one foot were retained for analysis (n=6).

Femoral movement within the stump tissues relative to the socket during gait

The biomechanical interaction between the prosthetic socket and the residual limb determines the quality of the fit and this included skeletal movement within the socket [12]. The understanding of this interaction and the development of quantitative measures to predict the quality of fit of the socket are quintessential for optimal socket design [12]. Various methods have been utilised to determine skeletal movement in both trans-tibial and trans-femoral sockets ranging from X-ray, magnetic resonance imaging (MRI) and ultrasound [28-33].

Of those technologies ultrasound is the most practical technology considering cost (MRI) and ionising radiation exposure (X-ray). Murray [31] reported on a study that validated the use of ultrasound for femoral movement within a prosthetic socket. Inaccuracies due to equipment limitations and those due to human error were identified and quantified. Ranges of flexion/extension and abduction/adduction of the residual femur within the socket during gait were estimated with a cumulative level of error of <1°.

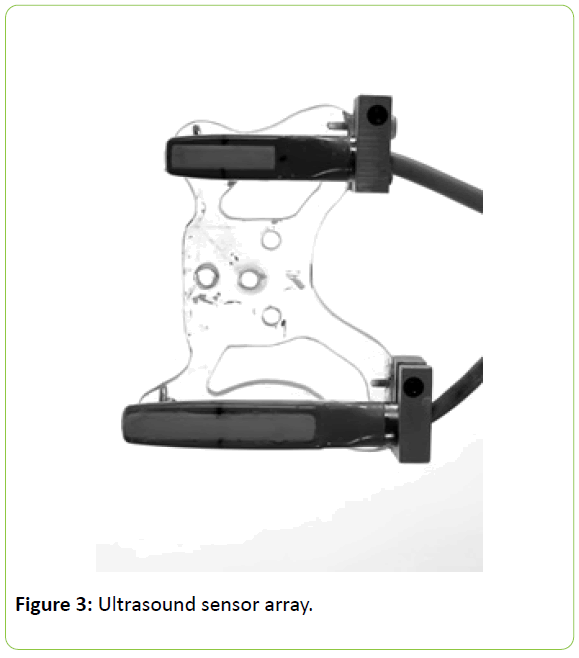

For this study, a Shimadzu™ SDU-400 diagnostic ultrasound scanner and two linear transducers with different scanning areas (40 mm and 80 mm) both operating in the 5 MHz frequency range were utilized.

The transducers were mounted on a custom designed and manufactured holder and spaced 120 mm apart. This created an array arrangement that is able to monitor skeletal movement on two level planes.

Furthermore, this assembly allowed the array to be transferred between the sockets without losing their spatial configuration (Figure 3).

Two rectangular windows were cut in the lateral aspect of the experimental sockets allowing the transducers to be in direct contact with the silicone liner to ensure appropriate acoustic transmission i.e. no air pockets/layers.

Ultrasound gel was directly applied to the residual limb over the transducer contact area before the silicone liner was applied. After application of the liner the prosthesis was donned as normal and the sensor array, smeared with gel, was mounted on the socket (Figure 4).

The data acquisition system consisted of: ultrasound equipment with external video output, a stationary video camera with a field of view in the sagittal plane of the subject and a video mixer/recorder to generate a digital split screen recording of the ultrasound image and visual gait data. Femoral movement data was recorded as the subject walked along a walkway in the gait lab.

Results

Dynamic stump-socket interface pressures during gait

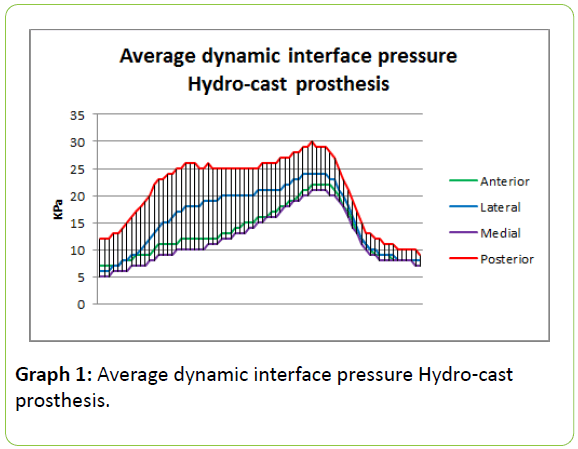

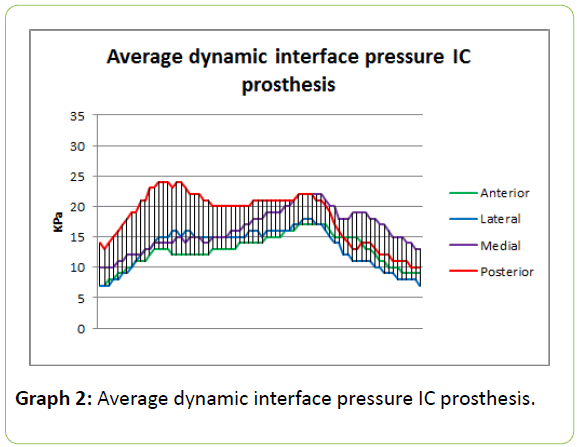

Results indicate that sockets produced by both conventional IC and HC techniques, generated similar dynamic interface pressures (Graphs 1 and 2).

It must be noted that the average pressure of the four sensor arrays for the HC system are more uniform during toe-off/ double support compared with that of the IC system. Although the HC socket exhibited elevated pressures on average, no significant clinical differences, <50 kPa [22], were detected.

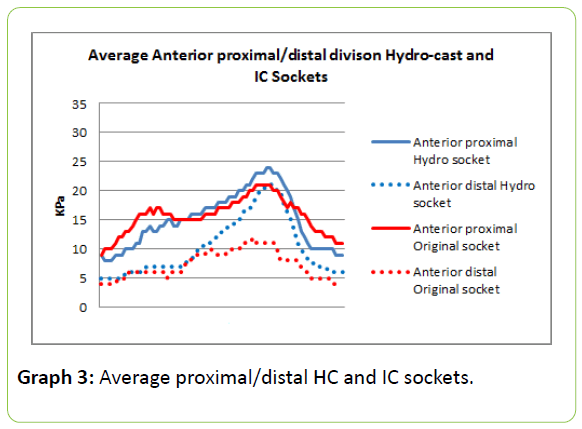

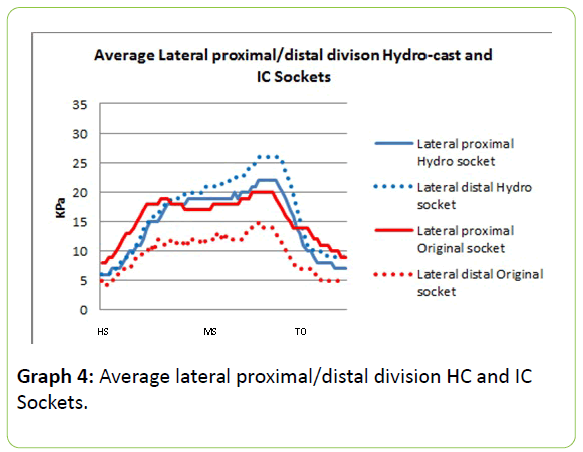

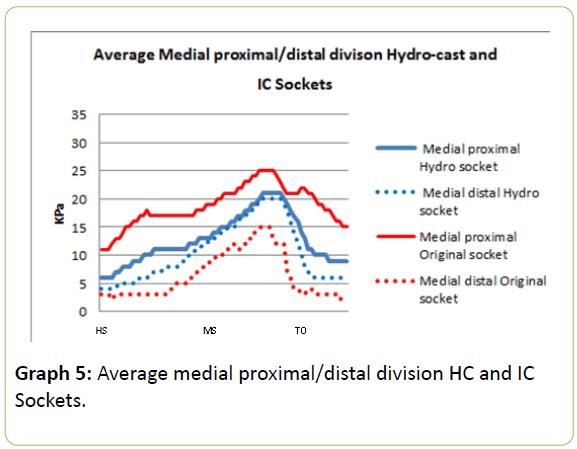

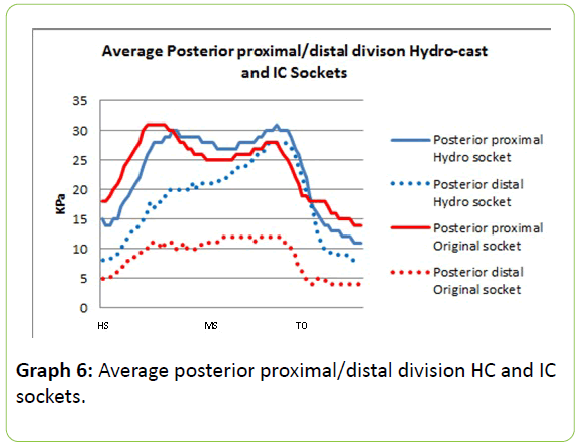

When the sockets were divided into proximal and distal regions, (Graphs 3-6), it was noted that the difference in regional average pressure for the HC socket was closer than for the IC socket.

Gait kinematics and kinetics

No marked differences were observed between the two conditions for any upper or lower body gait parameters or in the temporal and distance parameters (Table 1).

| Left (HC) | s.d. | Left (IC) | s.d. | Right (HC) | s.d. | Right (IC) | s.d. | |

|---|---|---|---|---|---|---|---|---|

| Walking Speed (m/s) | 1.30 | 0.024 | 1.33 | 0.031 | 1.31 | 0.026 | 1.33 | 0.048 |

| Stride Length (m) | 1.35 | 0.024 | 1.38 | 0.018 | 1.35 | 0.028 | 1.39 | 0.042 |

| Cadence (steps/min) | 116 | 1.63 | 116 | 1.81 | 117 | 2.05 | 115 | 1.17 |

| Double Support (s) | 0.24 | 0.0087 | 0.23 | 0.020 | 0.23 | 0.0075 | 0.24 | 0.019 |

| Single Support (s) | 0.46 | 0.010 | 0.44 | 0.0082 | 0.34 | 0.014 | 0.37 | 0.014 |

| Step Length (m) | 0.63 | 0.019 | 0.65 | 0.019 | 0.72 | 0.012 | 0.74 | 0.021 |

| Step Time (s) | 0.47 | 0.019 | 0.48 | 0.012 | 0.57 | 0.015 | 0.56 | 0.0082 |

| Step Width (m) | 0.21 | 0.017 | 0.16 | 0.014 | 0.21 | 0.016 | 0.17 | 0.012 |

Table 1: Temporal and Distance Parameters.

The most notable difference observed in the lower body was that the right (prosthetic) side peak knee flexion was slightly but consistently decreased by between 5 and 10 degrees with the HC socket prosthesis compared with the IC socket prosthesis. It appears that with the IC socket the subject ensures ground clearance with increased knee flexion, whereas with the HC socket it is via increased vaulting.

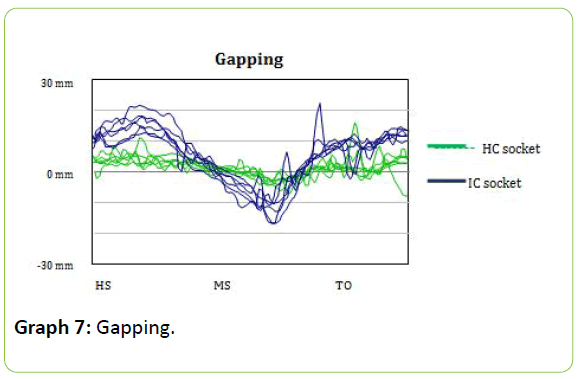

The range of relative movement between the pelvis markers and lateral socket wall (gapping) was reduced with the prosthesis with the HC socket by around 10-15 mm as illustrated in Graph 7. This shows the changing lateral distance between two markers, one placed on the lateral, most proximal aspect of the socket, and one placed directly above on the subject’s pelvis. This corresponds to ‘gapping’, a condition traditionally assessed by observation. The horizontal scale illustrates one gait cycle from initial contact to initial contact and the vertical scale is millimeters. Data collected from the IC socket is shown as a series of blues traces and data from the HC socket are green. The results show less gapping with the HC socket.

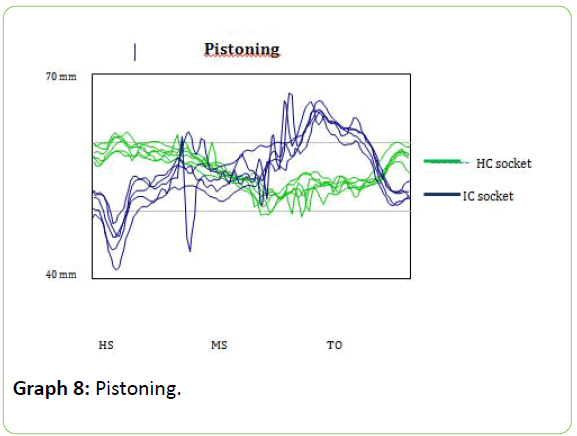

The pistoning data, illustrated in Graph 8, for the HC socket showed a decreased range of motion compared to the IC socket.

The IC socket result displayed an initial decrease in the longitudinal distance between the socket displacement markers in loading, as would be expected. During mid and terminal stance and pre-swing however, this motion then reversed and the distance increased.

With the HC socket the distance between the markers decreased through stance.

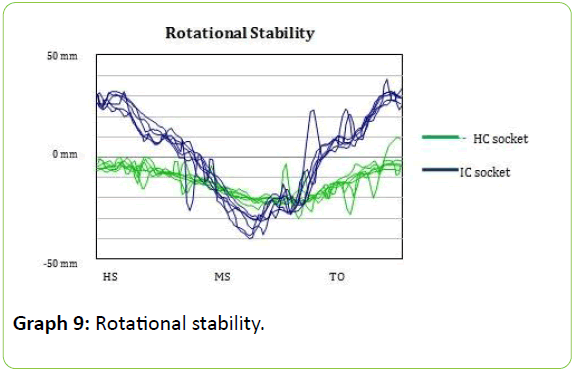

The rotational data as shown in Graph 9 showed that the rotational stability was increased within the prosthesis incorporating the HC socket.

Summary

• Speed slightly higher with the IC socket, but it was noted that the subject’s speed increased as she became more accustomed to the HC socket.

• Stride length slightly longer with the IC socket, affected via increased step length bilaterally.

• Cadence and double support time much the same for both Sockets.

• Single support time on the right a little decreased with the HC socket.

• Step width increased with the HC socket.

• Reduced gapping, pistoning and rotation measured within the HC socket.

Femoral Movement Relative to the Socket During Gait

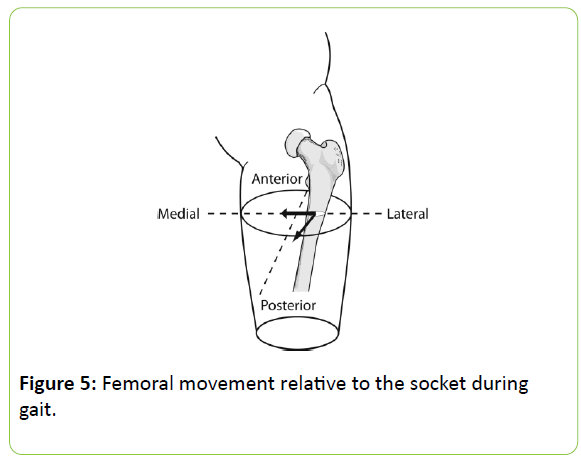

Two linear ultrasound sensors were fixed to the lateral wall of both socket designs. Motion of the femur relative to the socket was tracked as the subject walked at a self-selected walking speed. Results show that the dynamic motion of the femur within the IC prosthetic system progressed from the lateral socket aspect at heel strike towards the medial socket aspect (Figure 5 bold arrow). The dynamic femoral motion found in the HC prosthetic system indicated that the femoral progression started in the antero-lateral aspect and moved to the posteriorlateral aspect of the socket. (Figure 5 thin arrow) Moreover the range of movement was considerably less as compared with the IC prosthetic system.

Discussion

The dynamic interface pressure measurement results indicate that prostheses produced by both casting techniques, generated similar average dynamic interface pressures. That the average pressure was elevated for the prosthesis with the HC socket came as no surprise and might be directly related to the nature of casting under a full soft tissue loading condition. It is recognised that there might be an element of load transfer through the ischium (not measured) that could explain lower pressures in the IC socket. Similar pressure distribution findings between hands-on and hands- off casting concepts, although for trans-tibial prostheses, have been reported by Dumbleton et al. [4].

When pressure results were divided into proximal and distal regions, it was noted that the average pressures were more uniform for the prosthesis with the HC socket. Additionally, it was found that the proximal pressure on each of the sensor locations for the IC socket was higher than for the distal regions. To draw conclusions from interface pressure data alone is not possible from this sample size. It is also difficult to distinguish if the recorded pressure data is a result of axial loading, couples and moments, a direct result of alignment or socket shape related issues. Furthermore, there is growing consensus amongst researchers that interface shear force may be an even greater determinant of user comfort and socket fit. [14,15,24,34-44]

It was anticipated that although gait differences between socket designs were likely to be subtle, differences may be clinically significant. Therefore, it was necessary to develop gait analysis methods specific to the trans-femoral level of amputation that would be sufficiently sensitive to the changes introduced by the intervention. To date, kinematic and kinetic data have not been widely used to assess the socket-stump interface in amputees. This study started this process by measuring motion at the body device boundary: a process analogous to the prosthetists observational check of gapping and pistoning during gait as indicators of socket fit integrity. The gapping and pistoning were calculated as the absolute distance between two ‘socket displacement markers, one placed on the lateral proximal aspect of the socket and the other superior to it on the subject. The directions of these displacements were aligned with the thigh embedded axis system, with one axis between the hip joint centre and knee joint centre and one parallel with the knee flexion axis.

It was found that the range of socket gapping motion was reduced with the prosthesis with the HC socket. This finding is important as it implies a reduced soft tissue compliance “coupling stiffness” between the weight bearing structure, the skeleton and socket as predicted by the stiffest path principle [6,12]. The femoral stability data also support this hypothesis by indicating minimal femoral motion in the medio-lateral direction with the HC socket, as compared with the IC socket which demonstrated a greater range of motion with the femur progressing in the lateral-medial direction. The HC socket however showed more femoral motion in the anterio-posterio direction. Further investigation with a larger sample size is necessary to validate these results. The confounding factor of differing trim-lines must also be taken into consideration.

This pilot study on one subject has suggested that gait differences with the investigated sockets are likely to be subtle. This does not necessarily mean that the differences are clinically insignificant. It will therefore be necessary to develop and validate gait analysis methods specific to trans-femoral amputees which are sufficiently sensitive to the changes introduced by the intervention. As well as including standard gait parameters such as joint angle and moment, and ground reaction force data, this will also involve less commonly used measures, for example, joint center displacement, segment orientation and center of pressure progression.

To date, kinematic and kinetic data have not been widely used to assess the socket-stump interface in amputees, so it is proposed also to investigate methods by which this may be done. This pilot study started this process by measuring motion at the body device boundary: a process analogous to the prosthetist’s observational check of socket fit integrity.

Alternative approaches to the kinematic and kinetic assessment of interfacial stability should also be investigated. It has been suggested by Seliktar [45] for example, that the foreaft horizontal component of the ground reaction force can be used for this. It is therefore proposed to investigate the feasibility of this and other measures further.

The successful completion of this will not only play a vital role in the evaluation of the socket design philosophy, but could ultimately contribute to the wider field of clinical gait analysis in lower-limb prosthetic subjects by enhancing the objectivity of assessment in clinical prosthetics.

The range of relative movement between the pelvis and lateral socket wall (gapping) was reduced with the prosthesis with the HC socket by around 10-15 mm. This may however be because the IC socket extended more superiorly than the HC socket implying that a greater range of motion was possible with this condition. The pistoning data for the HC socket also showed a decreased range of motion by around 50 mm compared to the IC socket. The patterns of pistoning motion for the two sockets are surprisingly opposite. The IC socket shows an initial decrease in the longitudinal distance between the socket displacement markers in loading, as would be expected. During mid and terminal stance and pre-swing however, this motion then reversed and the distance increased. With the HC socket the distance between the markers decreased through stance. This finding could be explained by the coronal plane rotation of the socket on the residual limb, which also gives rise to the fact that gapping increased the longitudinal distance between the markers more than the compression in stance was decreasing it.

Adherents of the most widely used design philosophies for trans-femoral sockets have described how their approaches influence or control the motion of the femur relative to the stump tissues and the socket. [4,5] Although a case study, results indicate the possibility that the HC socket may offer improved medio-lateral stability compared to the IC socket as used by the test subject. This is also highlighted by Kahle [46] who removed different socket elements systematically in a case study examining trans-femoral socket design. This paper reported that femoral stability, one of the claimed benefits of the IC approach, was not influenced by the so-called bony-lock element of the design.

Conclusions

This study has demonstrated the feasibility of the HC approach, without modification, at trans-femoral level of amputation. Interface pressures using the HC method appeared to generate similar levels to the conventional IC approach during gait. Shear force at the interface could not be measured for this study, and would be an essential addition to continued work. Body motion and kinetic data showed similarities between limbs produced with the two designs. Differences in gapping and pistoning between the designs may be significant and should ideally be monitored in sync with pressure and shear data in a larger trial. The use of ultrasound to detect femoral motion identified that the IC design concept, which claims to stabilize the motion of the femur, may not be as effective as predicted in individual sockets due to the handcrafted method of manufacture. The motion of the femur within the tissues and the socket would be expected to provide a good indication of the quality of socket fit and yet this has never been exhaustively researched.

References

- Klute GK, Berge JS, Orendurff MS, Williams RM, Czerniecki JM (2006) Prosthetic intervention effects on activity of lower-extremity amputees. Arch Phys Med Rehabil 877: 717-722.

- Datta D, Harris I, Heller B, Howitt J, Martin R (2004) Gait cost and time implications for changing from PTB to ICEX sockets. Prosthet Othot Int 28: 115-120.

- Portnoy S, van Haare J, Geers RP, Kristal A, Siev-Ner I, et al. (2010) Real-time subject-specific analyses of dynamic internal tissue loads in the residual limb of transtibial amputees. Med Eng Phys 32: 312-323.

- Dumbleton T, Buis AW, McFadyen A, McHugh BF, McKay G, et al. (2009) Dynamic interface pressure distributions of two transtibial prosthetic socket concepts. J Rehabil Res Dev 46: 405-415.

- Almassi F, Mousavi B, Masumi M, Souroush MR, Honari G, et al. (2009) Skin disorders associated with bilateral lower extremity amputation. Pak J Biol Sci 12: 1381-1384.

- Bo Klasson (1995) Appreciation of prosthetic socket fitting from basic engineering principles. Glasgow (GB): National Centre for Training and Education in Prosthetics and Orthotics pp: 26.

- Buis AW, Condon B, Brennan D, McHugh B, Hadley D (2006) Magnetic resonance imaging technology in transtibial socket research: a pilot study. J Rehabil Res Dev 43: 883-890.

- Johansson S, Oberg T (1998) Accuracy and precision of volumetric determinations using two commercial CAD systems for prosthetics: a technical note. J Rehab Res Develop 35: 27-33.

- Hagberg K, Branemark R (2001) Consequences of non-vascular trans-femoral amputation: a survey of quality of life, prosthetic use and problems. Prosthet Orthot Int 25: 186-194.

- Gailey R, Allen K, Castles J, Kucharik J, Roeder M (2008) Review of secondary physical conditions associated with lower-limb amputation and long-term prosthesis use. J Rehabil Res Dev 45: 15-29.

- Sanders JE, Goldstein BS (2001) Collagen fibril diameters increase and fibril densities decrease in skin subjected to repetitive compressive and shear stresses. J Biomec 34: 1581-1587.

- Klasson B (2006) Prosthetic Socket Fit Implications of basic engineering principles. Advanced prosthetic science University of Strathclyde Glasgow p: 56.

- https://www.nasdab.co.uk.

- Long IA (1985) Normal shape normal alignment (NSNA) AK prosthesis. Clin Prosthet Orthot 9: 9-14.

- Ortiz RM (2007) MAS Design for trans-femoral prostheses. Orthop Tech 10-13.

- Sabolich J (1985) Contoured adducted trochanteric-controlled alignment method (CATCAM) Introduction and basic principles. Clin Prosthet Orthot 9: 15-26.

- Zahedi MS, Spence WD, Solomonidis SE, Paul JP (1986) Alignment of lower-limb prostheses. J Rehabil Res Dev 23: 2-19.

- Buis AW, Blair A, Convery P, Sockalingam S, McHugh B (2003) Pilot study: data-capturing consistency of two trans-tibial casting concepts, using a manikin stump model: a comparison between the hands-on PTB and hands-off ICECAST compact® concepts. Prosthet Orthot Int 27: 100-106.

- Kristinsson O (1993) The ICEROSS concept: a discussion of a philosophy. Prosthetics Orthotics Int 17: 49-55.

- Redhead RG (1979) Total surface bearing self suspending above-knee sockets. Prosthetics Orthotics Int 3: 126-136.

- Convery P, Buis AW (1999) Socket/stump interface dynamic pressure distributions recorded during the prosthetic stance phase of gait of a trans-tibial amputee wearing a hydrocast socket. Prosthet Orthot Int 23: 107-112.

- Buis AW, Convery P (1997) Calibration problems encountered while monitoring stump/socket interface pressures with force sensing resistors: techniques adopted to minimise inaccuracies. Prosthet Othot Int 21: 179-182.

- Polliack AA, Sieh RC, Craig DD, Landsberger S, McNeil DR, et al. (2000) Scientific validation of two commercial pressure sensor systems for prosthetic socket fit. Prosthet Othot Int 24: 63-73.

- Sanders JE (1995) Interface mechanics in external prosthetics: review of interface stress measurement techniques. Medical Biolog Eng Comp 33: 509-16.

- Mak AF, Zhang M, Boone DA (2001) State-of-the-art research in lower-limb prosthetic biomechanics-socket interface: A review. J Rehab Res Develop 38: 161-74.

- Woodburn J, Helliwell P (1997) Observations on the F-Scan in-shoe pressure measuring system. Clinical biomechanics, 1997. 12: S16.

- Woodburn J, Helliwell PS (1996) Observations on the F-Scan in-shoe pressure measuring system. Clin Biomec 11: 301-304.

- Convery P, Murray KD (2000) Ultrasound study of the motion of the residual femur within a trans-femoral socket during gait. Prosthet Othot Int 24: 226-232.

- Douglas TS, Solomonidis SE, Sandham WA, Spence WD (2002) Ultrasound imaging in lower limb prosthetics. IEEE Transactions Neural Systems Rehabil Eng 10: 11-21.

- Douglas TS, Solomonidis SE, Sandham WA, Spence WD (2002) Ultrasound image matching using genetic algorithms. Med Biol Eng Comput 40: 168-172.

- Murray KD, Convery P (2000) The calibration of ultrasound transducers used to monitor motion of the residual femur within a trans-femoral socket during gait. Prosthet Othot Int 24: 55-62.

- Lilja MT, Johansson, Oberg T (1993) Movement of the tibial end in a PTB prosthesis socket: a sagittal X-ray study of the PTB prosthesis. Prosthet Othot Int 17: 21-26.

- Tanner JE (2001) Radiographic Comparison of Vertical Tibial Translation Using Two Types of Suspensions on a Transtibial Prosthesis: A Case Study. J Prosth Orthot 1: 14-16.

- Segal AD, Orendurff MS, Klute GK, McDowell ML, Pecoraro JA, et al. (2006) Kinematic and kinetic comparisons of transfemoral amputee gait using C-Leg and Mauch SNS prosthetic knees. J Rehabil Res Dev 43: 857-870.

- Sanders JE (2000) Thermal response of skin to cyclic pressure and pressure with shear: a technical note. J Rehabil Res Dev 37: 511-515.

- Sanders JE, Bell DM, Okumura RM, Dralle AJ (1988) Effects of alignment changes on stance phase pressures and shear stresses on transtibial amputees: measurements from 13 transducer sites. IEEE Transactions Rehabil Eng 6: 21-31.

- Sanders JE, Daly CH (1993) Normal and shear stresses on a residual limb in a prosthetic socket during ambulation: comparison of finite element results with experimental measurements. J Rehab Res Develop 30: 191-204.

- Sanders JE, Daly CH (1999) Interface pressures and shear stresses: sagittal plane angular alignment effects in three trans-tibial amputee case studies. Prosthet Othot Int 23: 21-29.

- Sanders JE, Daly CH, Burgess EM (1992) Interface shear stresses during ambulation with a below-knee prosthetic limb. J Rehab Res Develop 29: 1-8.

- Sanders JE, Daly CH, Burgess EM (1993) Clinical measurement of normal and shear stresses on a trans-tibial stump: characteristics of wave-form shapes during walking. Prosthet Othot Int 17: 38-48.

- Sanders JE, Fergason JR, Zachariah SG, Jacobsen AK (2002) Interface pressure and shear stress changes with amputee weight loss: case studies from two trans-tibial amputee subjects. Prosthet Othot Int 26: 243-250.

- Sanders JE, Jacobsen AK, Fergason JR (2006) Effects of fluid insert volume changes on socket pressures and shear stresses: case studies from two trans-tibial amputee subjects. Prosthet Othot Int 30: 257-69.

- Sanders JE, Lam D, Dralle AJ, Okumura R (1997) Interface pressures and shear stresses at thirteen socket sites on two persons with transtibial amputation. J Rehabil Res Dev 34: 19-43.

- Sanders JE (2005) Changes in interface pressures and shear stresses over time on trans-tibial amputee subjects ambulating with prosthetic limbs: comparison of diurnal and six-month differences. J Biome 38: 1566-1573.

- Seliktar R (1994) Biomechanics of prosthetic gait. Phys Med Rehabil: State Art Rev 8: 89-107.

- Kahle JT (2002) A case study using fluoroscope to determine the vital elements of trans-femoral interface design. J Prosthet Orthot 14: 121-126.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences