Evaluation of Iranian Recycling Industries

Malek Hassanpour*

Department of Environmental Science, UCS, Osmania University, Telangana State, India

- *Corresponding Author:

- Malek Hassanpour

Department of Environmental science, UCS,

Osmania University, Telangana State, India.

Tel: 8978811723

Email: Malek.hassanpour@yahoo.com

Received Date: December 07, 2017; Accepted Date: December 12, 2017; Published Date: December 27, 2017

Citation: HassanpourM (2017) Evaluation of Iranian Recycling Industries. J Waste Recycl Vol.2 No.2:9

Abstract

Today, the rapid increase of the industrial activities and uncontrolled consumption of natural resources caused environmental problems. Recycling as a prominent strategy paved the way for developing recycling industries. Current research evaluated Iranian recycling industries according to Iranian industries organization database. By the way, six different types of recycling industries were evaluated based on technical, financial, input initial materials and energy consumptions via statistical methods. Iranian recycling industries include blown bitumen, plastic wastes, used motor oil and grease, oil filter, agricultural wastes recycling to cardboard and recycling silver of radiology films and its solution. The paired test analysis revealed significant differences between power-water and fuel-land among parameters such as initial feed, employees, power, water, fuel and land for 6 types of recycling industries (pvalue ≤ 0.016 and 0.023) respectively. Also, paired sample correlation analysis presented values of around 0.00 and 0.022 between both groups of plastic wastes recycling and recycling silver from radiology films and its solution and oil filter and motor oil and grease industries respectively. Also, it was found the highest values of about 0.99 between agricultural waste recycling to cardboard and plastic waste recycling industries by Pearson correlation analysis. The evaluation manifested the values of around (0.46), (1), (1.51), (1.06), (0.99) and (1.32) for initial feed, employees, power, water, fuel and land via max Z procedure respectively.

Keywords

Evaluation; Recycling industries; Wastes

Introduction

In the late 1970's, recycling was recognized as a prominent environmental issue and implemented many recycling industries over the wold. Nowadays, Industry managers, especially in developed nations, are looking for ways to protect the environment and to promote the performance of their organizations. Green supply chain is a type of supply chain in which environmental requirements are observed and products return to supply chain after spending their useful life. Its main purpose is descending the environmental pollutions from upstream to downstream of supply chain [1,2].

Based on database of Iranian industry organization, there are more than 200 recycling plants of used motor oil and grease which are currently participating in recycling operation via acid/ clay process. Annually, million tons of used oil are released after consumption in cars, vehicles and other usages then are taken to reprocessing and re-refining industries and withstand some processes such as heating, chemical materials addition and filtration steps to treat their secondary pollutants. Engine oils encompass 90% oil and less than 10% additive materials. Engine oil, hydraulic oil, lubricants oil, flux oil and wastes such as filter cake and acidic sludge are the final products of some facilities. In Iran, reprocessing of used motor oil has been commenced since 40 years ago and approximately 950000 tons of used oil is collected and recycled annually. Oil filters are used in part of the cars engine to purify the input pollutants into the engine. These filters need to be replaced after a certain period of time. Therefore, the useless oil filters are collected and transported to oil filters recycling industries [3-5]. One of the most important by-products generated by re-refining, refining and reprocessing operations of both used motor oil and crude oil treatments is bitumen materials which are exploited to produce blown bitumen etc in Iran. Bitumen materials are mixed and aerated at 232 to 190°C to generate blown bitumen. On the other words, the blown bitumen production operation mainly encompasses various stages of loading tanks, bitumen aeration, cooling and packaging [6,7].

The first industrial scale generation of plastics commenced in the 1940 globally. The basic raw material for plastic generation usually is naphta, come out from crude oil refining operations. Mattsson et al. [8] declared that around 280 Mt plastics released by 2012, 90% has been devoted to Low Density Poly Ethylene (LDPE), High Density Poly Ethylene (HDPE), Poly Propylene (PP), Poly Vinyl Chloride (PVC), Polyester (PS) and Poly Ethylene Terephthalate (PET) products. More than one third of this rate has been applied for packing usages like plastic bags and another third for housing appliances like plastic pipes and vinyl cladding, 10% end up in the oceans. The main applications for plastics in particular have been house ware, packaging, toys and construction usages. There are 7 kinds of plastics which are low-density, durable, formable and low-cost materials which do not decay, corrode, or dissolve, owning to their properties, are extensively employed in variety of fields, sectors and industries such as PET (13%, water and soda bottles), HDPE (17%, films, utensils, toys, pipe and processing equipment; bottles), PVC (3%, mix of hard plastic), LDPE (24%, dispersing bottles; wash bottles; tubing, plastic bags for computer components), PP (24%, milk bottles; most shampoo bottles), PS (7%, packaging; labeling textiles) and other plastics (12%, baby bottles; large water bottles; compact discs; medical storage containers) [9,10].

Silver, one of the precious and noble metals, is utilized in massive quantities for lots of purposes, especially in the photographic and radiology industries. It has been estimated that approximately 25% of the world's silver demands are afforded by recycling operation and that 75% of this is acquired from photographic wastes [11]. Using medical diagnostic by radiographic processing discharges effluents which carry hazardous contaminants for ambient, soil, water and food such as silver. The silver amounts reported in the washing water films and fixer samples ranged from 0.1 to 1,785.97 mg L−1 and 435.59 to 16,325.92 mg L−1 [12].

With regard to rise in amount of agricultural waste materials elevates the environmental pollution challenges. Recycling descends the demand for raw materials such as metals, forests, and oil and so reduces human’s impact on the environment. The cardboard generated from agricultural waste contains 90- 90% short fiber cellulose with the specifications and capabilities defined by national standard of Iran No. 1411. The cardboard is of a multi-layes type which each square meter comrises weigh over 180 g; due to the required strength and flexibility is mainly utilized in packaging industry. In the production of cardboard, the main applied materials are agricultural wastes such as plants stems and straw [13].

Lots of small recycling units of blown bitumen, agricultural wastes to cardboard, recycling silver from rsdiolog and photogragpy films and its solution, oil filter, used motor oil and grease and plastic wastes recycling industries have been currently implemented and modern technologies and facilities are developing continuously in Iran. On the other hand, aforementioned recycling industries have properly accommodated effective technologies for recovering and treating, and recycling of wastes from disposed products and regard to majority of existing industries in developing countries and the world, quality of released products and quantity of application, it is indispensable to consider the financial aspects, input materials, energy demands of recycling industries. Evaluation of recycling industries by current research comprises the different components of the financial, materials supplement and equipment demands aspects of industries and examines closely the correlations among them. The major parts can be divided into energy consumption estimations for water, fuel, power, land, employees and initial feed. The results of study by Hassanpour et al. [6,10] manifested economic viability and feasibility for both of plastic wastes and blown bitumen recycling industries. The survey of technical and economical view-point by Jonidi and Hassanpour et al. [14] indicated economic success of used motor oil and grease recycling industries in Iran. Other study by Jonidi et al. [15] evaluated feasibility of implementation; acidic sludge recycling unit for used motor oil reprocessing industries in Iran. Gulzar et al. [16] experimentally obtained that the strong base oil filter improved the lubricant’s physical and tribological properties. Therefore, oil filter modification recommended in generating and recycling procedures based on initial applied materials. The main objective of present study was evaluation of Iranian recycling industries. To achieve this purpose, was investigated requirements of the industries based on financial, materials supplement and energy demands.

Materials and Methods

Statistic test

IBM SPSS Statistic 20 software was used to analysis the data of recycling industries. Data related to recycling industries extracted from database released by Iranian industries organization.

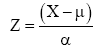

A model of evaluation

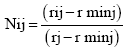

In order to prioritize the existing main factors among recycling industries were used eqns. (1)-(3). Data was sorted from the smallest to largest and then was used eqn. (1).

(1)

(1)

(2)

(2)

(3)

(3)

In these equations Z, X, μ, α, Znew, Zold and Min Zj are standard number for each existing item in matrix, existing item in matrix, average of values in the particular column, standard deviation of each column, new item, obtained item of previous step and existing minimal item in column j [17].

Results and Discussion

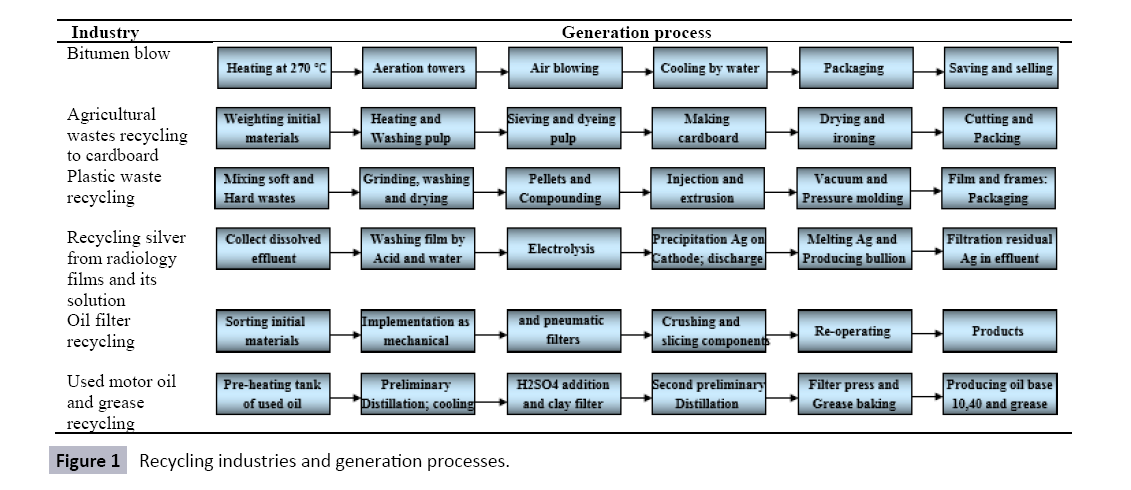

Green purchasing is defined as an environmentally conscious purchasing initiative that tries to ensure that purchased products or materials meet environmental objectives set by the purchasing firm, such as reducing the sources of wastages, promoting recycling, reuse, resource reduction, and substitution of materials. Tables 1-4 display recycling industries and generation processes, required initial materials, available devices and facilities and energy consumption estimations respectively.

Table 1. Recycling industries and required initial materials.

| Industry | Initial materials |

|---|---|

| Bitumen blown | Bitumen 60/70 (61600t); Barrels of 220 l (60000 No); Cartons of 35 kg (34300 No); Raw oil (5400t) |

| Agricultural wastes recycling to cardboard | Agricultural wastes (2700t); NaOH (10800 Kg); NaCO3 (5400t); HClO (5400 Kg); Plastic for packaging with dimensions of 6 × 81 × 121 (44400 m2) |

| Plastic waste recycling | LDPE or PE (1000t) |

| Recycling silver from radiology films and its solution | Used films especially in radiology usages containing 3.5 g/kg silver (8t); Fixed solution of photograghy lab or radiology usages containing 9 g/l (27000 l); Bleach solution fixed (27000 l); NaOH 100% (550 kg); H2SO4 96-98% (550 kg); HNO3 70-75% (1350 kg); Additives (5500 kg) |

| Oil filter recycling | Used oil filter (1200t); Metal and non-metallic waste products (800t); Solvent of hydrogen fluoride (20L) |

| Used motor oil and grease recycling | Used oil (5770 m3); H2SO4 (411.3t); Cao (22.5t); Bentonite soil (312.5t); Additives (66t); Fat acid (112.5t); Containers of 4 l (765000 No); Containers of 1 kg (787500 No); Cartons, 24 kg of grease (34453 No); Cartons of 6 empty spaces (122500 No) |

Table 2. Recycling industries and available devices and facilities.

| Industry | Devices and facilities |

|---|---|

| Bitumen blown | Compressor or centrifuge (capacity of 22 m3/min) (2 No); Aeration tower (45t, Cs, thickness of 5 mm) (1 No); Bitumen conveyor pump (17 Atmosphere) (2 No); Condenser with capacity of 85 m3/min (V=3m3) (1 No); Storage tank (70t) (4 No); Flame (3 Hp) (7 No); Kiln (2 × 2 × 3 m) (1 No); Fitted lab (1 unit); Repair shop (1 No) |

| Agricultural wastes recycling to cardboard | Centrifuge feeding pump (1 No); Mixing tank covered by epoxy insulator (1 No); Under pressure tank, thickness of 15 mm covered by epoxy insulator (4 No); Tank with capacity of 60000 L (1 N0); Storage tank, 400 l (8 No); Material conveyor system (1 No); Pumps of 1-20 Hp (5 No); Cardboard making machine, L=12m, width=1.1 m (1 No); Drying machine 5 Hp (1 No); Cardboard ironing machine, equipped to thermometer and gearbox, 10 Hp (1 No); One-ton bascule (1 No); Cutting machine (1 No); Refiners PFI Mil (1 No) |

| Plastic waste recycling

|

Grinder machine equipped to washing machine (500 kg/h-automatic 40 Hp) (1 No); Conveyor system 2.5 m (1 No); Stainless steel washing chamber (2 m3) (1 No); Automatic dewatering machine (2 m3 stainless steel) (1 No); Drying machine equipped to flame and fan (1 m3 stainless steel) (1 No); Device to produce the pellets (Twine, 100 kg/h); Storage cone (L=2 m) (1 No); Packaging machine, 5o kg packs (1 No) |

| Recycling silver from radiology films and its solution | Steel tank covered by PVC, 1 m3, (2 No); Electrolysis system equipped to recirculation pump to sediment silver, 1.5 kw (1 No); Pumps of 1 kw (3 No); Coal filter, 0.5 m3 (1 No); Washing tank (1 No); Tank for Ag separation from films, 1 m3 (1 No); Melting kiln, 1000°C, 12 l (1 No); Ingot molds (20 No); Plastic containers (30 No); Fan equipped to channel and electromotor (1 No); Storage tank, 5 m3 (1 No); Strongbox to preserve the ingots (1 No); Fitted lab (1 unit) |

| Oil filter recycling

|

Sorting machine, L=3 m (1 No); Mechanically-pneumatic breaker machine, 10 No/min (1 No); Separating machine, 10 No/min (1 No); Grinder, 15 No/min (1 No); Treatment machine (1 No); Drying machine, L=2 m (1 No); Conveyor system, L=3 m (1 No); Steel storage tank, 2 m3 (1 No) |

| Used motor oil and grease recycling | Underground chamber 12 × 15 × 2 m made by concrete (1 No); Sedimentation tank (20 m3) (7 No); Distillation tanks of (20 m3) (4 No); Mixing tanks (5 No); Grease cooking chamber (1 No); Filter press with 20 blades (62 × 62) (1 No); Propeller mixers with power of 3.5 Hp (1 No); Sewage pumps with power of 10 hp (1 No); Stainless steel vacuum pumps with power of 7.5 hp (2 No); Gear pump with power of 5.5 hp (11 No); Condenser, capacity of 800 l/min (2 No) |

Table 3. Recycling industries and energy consumption estimations.

| Land (m2) | Fuel (Gj) | Water (m3) | Power (kw) | Employees | Initial feed (t) | Nominal capacity (t) | Industry |

|---|---|---|---|---|---|---|---|

| 2800 | 12 | 12 | 405 | 19 | 67000t+94300 No | 27000 | Blown bitumen |

| 10300 | 41 | 34 | 316 | 67 | 2721.6t+44400 m2 | 1350 | Agricultural wastes recycling to cardboard |

| 7600 | 9 | 6 | 339 | 9 | 1000t | 630 | Plastic waste recycling |

| 1100 | 2 | 3 | 41 | 7 | 69.9t | 40.40 | Recycling silver from radiology films and its solution |

| 2400 | 3 | 4 | 71 | 16 | 2000t+20 L | 2000 | Oil filter recycling |

| 3900 | 34 | 29 | 194 | 20 | 5570 m3+924.8t+1709453 No | 10500 | Used motor oil and grease recycling |

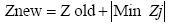

Table 4. Correlation analysis.

| Paired samples correlations | N | Correlation | Sig. |

|---|---|---|---|

| Pair 1 blown bitumen recycling and agricultural wastes recycling to cardboard | 7 | 0.073 | 0.876 |

| Pair 2 Plastic wastes recycling and recycling silver from rsdiology films and its solution | 7 | 0.997 | 0.000 |

| Pair 3 Oil filter recycling and motor oil and grease recycling | 7 | 0.825 | 0.022 |

It has a worth to mention that in the Table 4 was used the amounts based on ton unit in the column of initial feed to compute both of max Z and statistical analysis and was neglected values based on liter and numbers. Figure 1 represents the correlation among recycling industries based on nominal capacity, initial feed, employees, Power, water, fuel and land values. Pair sample test does not reveal any significant difference for same conditions (for 7 variables in Table 5) Correlation analysis among recycling industries (This study)

Figure 1: Recycling industries and generation processes.

Table 5. Correlation analysis among recycling industries.

| Motor oil and grease recycling | Oil filter recycling | Recycling silver from radiology films and its solution | Plastic wastes recycling | Agricultural wastes recycling to cardboard | Blown bitumen recycling | Pearson correlation Sig. (2-tailed) N | |

|---|---|---|---|---|---|---|---|

| 0.627 | 0.604 | -0.140 | -0.066 | 0.073 | 1 | Blown bitumen recycling | |

| 0.132 | 0.151 | 0.764 | 0.888 | 0.876 | |||

| 7 | 7 | 7 | 7 | 7 | 7 | ||

| 0.294 | 0.750 | 0.977 | 0.990 | 1 | 0.073 | Agricultural wastes recycling to cardboard | |

| 0.522 | 0.052 | 0.000 | 0.000 | 0.876 | |||

| 7 | 7 | 7 | 7 | 7 | 7 | ||

| 0.210 | 0.668 | 0.997 | 1 | 0.990 | -0.066 | Plastic wastes recycling | |

| 0.651 | 0.101 | 0.000 | 0.000 | 0.888 | |||

| 7 | 7 | 7 | 7 | 7 | 7 | ||

| 0.148 | 0.611 | 1 | 0.997 | 0.977 | -0.140 | Recycling silver from radiology films and its solution | |

| 0.751 | 0.145 | 0.000 | 0.000 | 0.764 | |||

| 7 | 7 | 7 | 7 | 7 | 7 | ||

| 0.825 | 1 | 0.611 | 0.668 | 0.750 | 0.604 | Oil filter recycling | |

| 0.022 | 0.145 | 0.101 | 0.052 | 0.151 | |||

| 7 | 7 | 7 | 7 | 7 | 7 | ||

| 1 | 0.825 | 0.148 | 0.210 | 0.294 | 0.627 | Motor oil and grease recycling | |

| 0.022 | 0.751 | 0.651 | 0.522 | 0.132 | |||

| 7 | 7 | 7 | 7 | 7 | 7 |

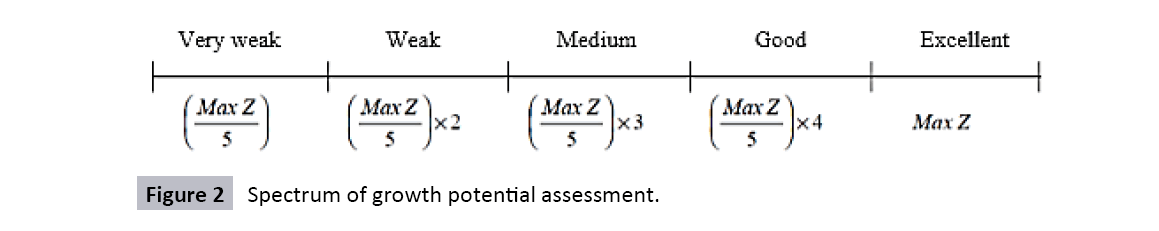

According to Table 5 were found values of around 0.99, 0.977, 0.977 and 0.825 as correlation results among industries; agricultural wastes recycling to cardboard/plastic wastes recycling, agricultural wastes recycling to cardboard/recycling silver from radiology films and its solution, plastic wastes recycling/recycling silver from radiology films and its solution and oil filter recycling/motor oil and grease recycling industries respectively. Narimisa and Narimisa et al. [18] evaluated factors such as social, environmental, land use, economical factors in main criteria of the paired comparisons matrix of Isfahan oil refinery in operation. Obtained results prioritized as economic > land use > environmental > social factor. To compute max Z were estimated the mean and standard deviation of data. Figure 2 displays mean, standard deviation, standard error mean and paired sample test. Mean, Std.Deviation, Std. Error Mean and paired sample test among recycling industries (Tables 6 and 7).

Table 6. Mean, Std. Deviation and Std. Error Mean.

| N | Mean | Std. Deviation | Std. Error Mean | |

|---|---|---|---|---|

| Initial feed | 6 | 12390.9000 | 267663.94794 | 10926.33599 |

| Employees | 6 | 23.0000 | 22.19009 | 9.05907 |

| Power | 6 | 227.6667 | 149.77806 | 61.14664 |

| Water | 6 | 14.6667 | 13.50062 | 5.51160 |

| Fuel | 6 | 16.8333 | 16.58212 | 6.76962 |

| Land | 6 | 4683.3333 | 3528.97530 | 1440.69813 |

Table 7. Mean, Std. Deviation, Std. Error Mean and paired sample test among recycling industries.

| Paired difference | t | df | Sig. (2-tailed | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Std. Deviation | Std. Error Mean | 95% confidence interval of the difference | ||||||

| Lower | Upper | ||||||||

| Pair 1 | Initial feed-Employees | 12367.90000 | 26765.37847 | 10926.92000 | -15720.64208 | 40456.44208 | 1.132 | 5 | 0.309 |

| Pair 2 | Power-Water | 213.00000 | 145.46890 | 59.38743 | 60.33975 | 365.66025 | 3.587 | 5 | 0.016 |

| Pair 3 | Fuel-Land | -4666.50000 | 3518.04325 | 1436.23514 | -8358.45997 | -974.54003 | -3.249 | 5 | 0.023 |

In the following, values were obtained around (0.919, 0.0111, 0.0699, 0.0111), (0.22, 0.7, 0.75, 0.020), (0.196, 0.5, 0.84, 0.258), (0.16, 0.25, 0.260, 0.772), (0.142, 0.66, 0.12, 0.75), (0.764, 0.266, 0.23, 0.578) for initial feed, employees, power, water, fuel and land using eqn. (1). These values can be employed to prioritize the factors. Employing eqns. (2) and (3) for the values resulted to amounts of around (0.46), (1), (1.51), (1.06), (0.99) and (1.32) for the max Z values respectively. Obtained values can be used to prioritize factors in the weighting systems of Delphi Fuzzy Logistic according to Cavallaro et al. [17] investigated the combined heat and power systems applying fuzzy shannon entropy and Fuzzy TOPSIS to prioritize the factors so it resulted to a classification style as gas turbine > steam turbine > fuel cell > reciprocating engine > micro-turbine. To compute max Z values were used the mean and standard deviations amounts of Figure 1. Spectrum of Growth Potential Assessment.

Abdollahi et al. used variance and regression analysis to figure out the major effects of input parameters upon properties of sintered iron/recycled grey cast iron powder metallurgy sections [19]. Moharamnejad et al. [20] evaluated the consumption of energy, water, airplanes fuel and environmental pollutants in Iran Aseman Airline Company. Accordint to study of Ahmadi and Ahmadi [21] data envelopment analysis models can provide efficiency scores scaled to a maximum value of 1 to evaluate efficiency and inefficiency of industries. So, obtained results revealed amounts of around 0.591, 0.418 and 0.484 for Iranian recycling industries at efficiency scale, while values were about 1, 1, and 1 at pure technical efficiency during 2005, 2006 and 2007 respectively. Zahorska et al. [22] assigned statistical analysis to evaluate the waste management in the company RIBE Slovakia, Nitra factory including technologies (cutting operations, metal cold-forming, thread rolling, metal surface finishing, automatic sorting, metrology, assembly), in terms of strengths and weaknesses points, as well as identification of the opportunities and potential threats. Obtained results represented that waste management system is combined into the company management system can procure lots of advantages. Galarpe et al. [23] used statistical evaluation style in potential recovery of silver from X-ray fixer waste by alkaline treatment. One way ANOVA proved that there were significant differences on the value of silver recovered when varying the NaOH additions.

Hassanpour et al. [10] found the indices values such as valueadded percent, profit, annual income, breakeven point, valueadded, output value, data value, variable cost of commodity unit and production costs to be approximately 62%, $366558, $364292.6, $100.34, $423451.25, $255335.75, $678787, $389.65 and $314494.4 for plastic wastes recycling industries respectively. The breakeven point about 15.93%, the time of return on investment about 1.12 (13.7 months) proved that this industry relatively needs to extensive time to repay the initial investment and starts gaining income. Hassanpour et al. [6] figured out that the indices values such as value-added percent, profit, annual income, breakeven point, value-added, output value, data value, variable cost of commodity unit and production outlays about 44%, $5308605.14, $5252251.65, $1183.67, $5401935.47, $6748064.5, $12150000, $140.93 and $6897748.4 for blown bitumen recycling industries respectively. The breakeven point about 2.46%, time of return on investment about 0.07, high business excellence scores offered a systematic practice so that cut back outlays and distinguish the strength and weakness points to promote. Jonidi et al. [15] investigated the economic indices for acidic sludge recycling unit of used motor oil and grease recycling industries and findings proved united success of the plant pertaining on breakeven point of about 14.7% and the time of return on investment 1.05 (about 13 months). Iranian industries organization achieved to low breakeven point of about 22.5% and the time of return on investment 0.9 (about 11 months) that supported economic success used motor oil reprocessing industries [24].

Conclusion

Iranian industries continue to improve their environmental image through cleaner production and investment in environmental protection. They seek to develop systematic and integrated approaches to environmental management such as industrial ecology for moving towards closed-loop or cyclical industrial systems. To improve the performance, Iranian manufacturing enterprises should develop necessary standards in material, machines, equipment, instruments purchasing and also in product and process designing; implement environmental standards; reduce energy and material consumption; train employees about environmental issues, etc.

References

- Rhamin H, Madhoushi M, Ebrahimi A, Faraji F (2013) Effect of resin content, press time and overlaying on physical and mechanical properties of carton board made from recycled beverage carton and MUF resin. Life Sci J 10: 613-619.

- Hassanpour M (2014) Evaluation of sustainable development using business excellence model in used motor oil industries. Iranian J Health Safety & Environment 1: 59-66.

- Hassanpour M, Mohammadi A (2012) Management strategies of used motor oil. 5th National Conference & Exhibition on environmental. www.nlai.ir.

- Jonidi JA, Hassanpour M (2013) Used Motor Oil Management. (1stedn), Tehran: Ebadi Far publication. www.nlai.ir.

- Jonidi J A, Hassanpour M (2015) Analysis and comparison of used Lubricants, Regenerative Technologies In the World. 103: 179-191.

- Hassanpour M (2016) A management and economic survey in implementation of blown bitumen production using acidic sludge recycling (A case study). Iranian J Health Safety & Environment 3: 604-617.

- Unnisa SA, Hassanpour M (2017) Development circumstances of four recycling industries (used motor oil, acidic sludge, plastic wastes and blown bitumen) in the world. Renewable and Sustainable Energy J 72: 605-624.

- Mattsson K, Hansson LA, Cedervall T (2015) Nano-plastics in the aquatic environment. Environ. Sci.: Processes Impacts 17: 1712-1721.

- Comaniţa ED, Ghinea C, Hlihor RM (2015) Challenges and oportunities in green plastics: an assessment using the electret decision-aid method.Environmental Engineering and Management J 14: 689-702.

- Hassanpour M(2015) Survey economic indices of plastic wastes recycling industry (A case study). Iranian J Health Safety & Environment 2: 366-373.

- Nakiboglu N, Toscali D, Nisli G (2003) A Novel Silver Recovery Method from Waste Photographic Films with NaOH Stripping. Turk J Chem 27: 127-133.

- Grigoletto JC, Segura-Munoz SI, Barbosa-Junior F, Sanches SM, Takayanagui AMM (2011) Silver Discharged in Effluents from Image-Processing Services: a Risk to Human and Environmental Health. Biol Trace Elem Res 144: 316-326.

- Bahrami A, Soltani N, Pech-Canul MI, Gutierrez CA (2016) Development of metal-matrix composites from industrial/agricultural waste materials and their derivatives. Critical Reviews in Environmental Science and Technology 1-66.

- Jonidi J A, Hassanpour M (2014) Survey of economic indices of the used motor oil industry equipped to acidic sludge recycling unit (A case study). Merit Res J Engineering, Pure and Applied Sci 2: 22-29.

- Jonidi JA, Hassanpour M, Farzadkia M (2016) Economic evaluation of recycling acidic sludge project of reprocessing industries to bitumen (a case study). Environmental Technology & Innovation 5: 30-40.

- Gulzar M, Masjuki HH, Kalam MA, Varman M, Fattah IMR (2015) Oil filter modification for biodiesel–fueled engine: A pathway to lubricant sustainability and exhaust emissions reduction. Energy Conversion and Management 91: 168-175.

- Cavallaro F, Zavadskas EK, Raslanas S (2016) Evaluation of Combined Heat and Power (CHP) Systems Using Fuzzy Shannon Entropy and Fuzzy TOPSIS. Sustainability 8: 2211-2219.

- Narimisa MR, Narimisa MR (2016) The Research of Environmental Impact Assessment for oil refineries in Iran Based on AHP and GIS. Int J Humanities and Cultural Studies 1396-1416.

- Abdollahi H, Mahdavinejad R, Leavoli RP, Ghambari M, Moradi M (2014) Investigation and optimization properties of sintered iron/ recycled grey cast iron powder metallurgy parts. J Engineering Manufacture 228: 493-503.

- Moharamnejad N, Azarkamand S (2007) Implementation of green productivity management in airline industry. Int J Environ Sci Tech 4: 151-158.

- Ahmadi V, Ahmadi A (2012) Application of Data Envelopment Analysis in manufacturing industries of Iran. Interdisciplinary Journal of Contemporary Research in Business 4: 534-544.

- Zahorska R, Nozdrovicky L, Mikulasik L (2016) Implementation of Statistical Methods and SWOT Analysis for Evaluation of Metal Waste Management in Engineering Company. Acta Technologica Agriculturae 19: 12-16.

- Galarpe V, Leopoldo GD (2017) Potential Recovery of Silver (Ag) from X-ray Fixer Waste by Alkaline Treatment. Engineering, Technology & Applied Science Research 7: 2094-2097.

- Hassanpour M (2014) Cost management of projects using a standard PMBOK in engineering projects. International Journal of Engineering Sciences & Research Technology 4: 137-147.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences