Environmental Health Risk Assessment of Asbestos-Containing Materials in the Brewing Industry in Ghana

Edward Kweku Nunoo1*, Anthony Panin2 and Bernice Essien3

1Institute for Oil and Gas Studies, University of Cape Coast, Ghana

2School of Graduate Studies, Central University Accra, Ghana

3Department of Nursing/Psychology, Central University Accra, Ghana

- *Corresponding Author:

- Edward Kweku Nunoo

Institute for Oil and Gas Studies

University of Cape Coast, Ghana

Tel:+233 26 856 9965

E-mail: edward.nunoo@ucc.edu.gh

Received date: October 20, 2018; Accepted date: November 08, 2018; Published date: November 13, 2018

Citation: Nunoo EK, Panin A, Essien B (2018) Environmental health risk assessment of asbestos-containing materials in the brewing industry in Ghana. J Environ Res Vol.2: No.2:8.

Abstract

This paper assessed asbestos-containing materials (ACMs) in the brewery industry to determine and document the presence or otherwise of presumed or known ACMs. The study also elicited views on ACMs presence in the workplace using simple random and purposive method within the field survey design construct. Out of 38 bulk samples taken in the Northern sector (BFN, Kumasi), 14 (39%) confirmed presence of asbestos. In the southern sector (BFS, Accra), 51% of bulk samples (N=101) taken also confirmed presence of ACMs fibers. Identified ACMs were of the amosite and chrysotile types and found mainly as insulation materials. Airsamples did not indicate concentrations of asbestiform fibers. ACMs with higher material assessment scores (MAS) ≥ 12 and risk priority action scores (PAS) ≥ 14, per the existing thresholds in the industry, were of the highest health concerns. There was significant evidence (p>0.02) to confirm established premise that the level of awareness of ACM’s presence in the workplace was low. Duty holders and workers were not sufficiently aware of their work environment and rights to warrant institutionalization of effective asbestos control programmes (ACP). To mitigate and cope with risk, the paper concludes that, given this peculiar situation in the workplace and the long latency period for asbestos related diseases, effective asbestos control and abatement programmes (ACP) need to be implemented to imbibe in workers a culture of strict adherence to the policies and programmes. This is needful to diffuse the idea that asbestos related diseases will be largely restricted to the developing economies in the next few decades.

Keywords

Asbestosis; Asbestos control awareness; Asbestos register; Brewery industry; Environmental health risk; Material assessment score

Introduction

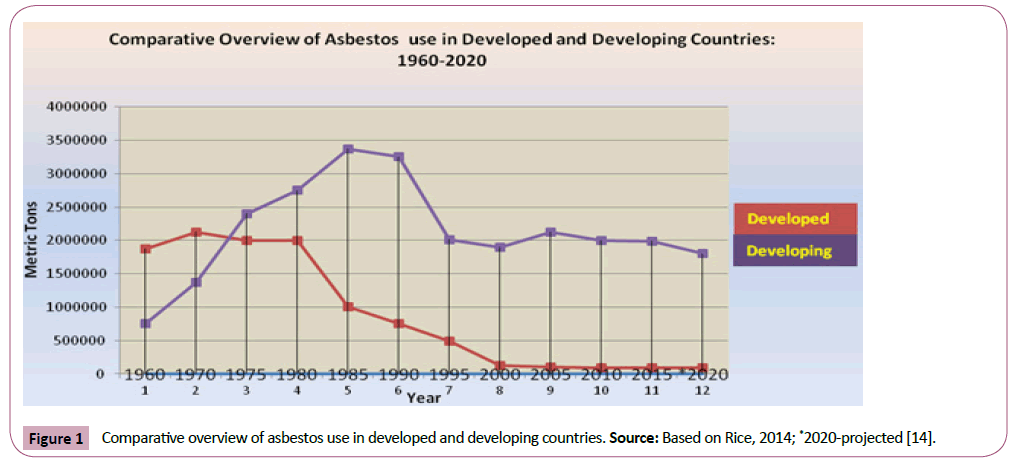

Several studies have concluded on a number of health-related hazards resulting from exposure to all forms of asbestos under friable conditions [1,2]. These hazards, according to WHO, include asbestosis, mesotheliomas and related lung cancers. Inferring from Iliopoulou et al. Sen, LaDou and WHO, ill-health associated with ACMs occur at low levels of exposure, but with serious cumulative impact over time [3-7]. Lin et al. corroborates this assertion in their findings on ‘ecological association between asbestos related diseases and historical asbestos use that ‘mortality rates of asbestos-related diseases in the early 2000s correlate to aggregate asbestos use during the 1960s’, a latency period of 40 years [8,9]. Consequently, the use of ACMs has been banned in most developed economies [1,10,11], but not without resistance from the asbestos industry and some wealthy business entrepreneurs [12,13]. Although there are mixed reactions to total ban on use of ACMs in the United States of America (USA), it is strictly regulated [12]. In emerging economies, however, notably Brazil, Ghana, Senegal, Zambia and South Africa, consumption of ACMs is high (Figure 1), with major concerns coming from exposure to ACMs in factories, handling of housing products, and construction and the built environment [14-17]. The use of asbestos in developed economies peaked in 1970 and stabilised through to 1980 (Figure 1). Within the same time, consumption was relatively high and rising faster in developing economies. After a complete ban in 1985, the use of ACMs declined at a faster rate and again stablised at very low levels at the turn of the millennium until date in the developed countries. The use of ACM trajectories in developing economies, over the same period was, comparatively, very high (Table 1), although usage had declined and stabilised between 1985-2015, with a tendency to decline further by 2020.

Figure 1: Comparative overview of asbestos use in developed and developing countries. Source: Based on Rice, 2014; *2020-projected [14].

The main goal of this study is to perform an environmental health risk assessment of ACMs in the brewery industry, document scientific evidence that reiterates dangers associated with friable asbestos in the workplace, related health risks and to contribute to knowledge needed by management of duty holders to enforce hazardous substance management discipline in the workplace, in accordance with best working practices.

Specifically, the paper determined and documented the extent of presumed or known ACM’s, recorded different types of asbestos in two brewery facilities (Appendix A and B) by collecting a reasonable number of representative ACM samples for laboratory analysis, and assessed the level of knowledge of ACM presence in the working environment and its associated health related risk.

Statement of the problem

Presently, the use of asbestos is managed by only economic interest, as there are no regulations in most developing countries regarding the regulation and use of asbestos. Awareness of its presence and dangers associated with ACMs in the workplace by duty holders and workers is also very low, although enough scientific evidence exists to suggest that hazardous substances are present in the working environment. Field surveys conducted in two major cities (Accra and Kumasi) in Ghana, between the months of August and October 2017, indicate that ACMs are openly traded in building hardware shops unregulated and without any form of protection and precaution on the part of vendors and their clients [10,18,19]. Handling of deteriorating ACMs in homes, establishments, motor cars (inside roof panel and engines) and other machine plants are also not properly managed due to ignorance. Dangers associated with exposure to ACMs are well known and documented in developed economies [7,10], but not in emerging ones, as documented evidence to this effect, especially in the brewery industry in Ghana is scanty [20,21] or virtually non-existent. The Environmental Protection Agency (EPA) of Ghana, however, advises on methods for handling and disposing of hazardous substances in general, when consulted. The presence of asbestos in any workplace warrants constant monitoring to establish if workers are at risk. This would enable management and regulatory agencies to target employees with exposures in excesses of permissible exposure levels (PELs) or other set standards for interventions to reduce or eliminate exposures. Effective asbestos control program (ACP) in the workplace will depend, in part, on the knowledge, attitudes and practices of the workers. Management (duty holders) is obliged to play a major role by providing personal protective equipment (PPE) at the workplace and imbibing in them the culture of strict adherence to policies and programs geared at protecting their safety and health. Where gaps in knowledge, and undesirable working attitudes exist in relation to asbestos, educational intervention (capacity building, awareness training, sensitization programmes) can be designed and implemented to correct them.

Asbestos: Characteristics and physical properties

The Health and Safety Executive document, (HSE) defines asbestos as any fibrous silicates of asbestos actinolite, asbestos grunerite (amosite), asbestos anthophyllite, chrysotile, crocidolite, and asbestos tremolite [22-24]. The Analysts Guide for Asbestos Sampling (HSG247) [22], under guidance 2, regulations 2 (1) of the HSE document, broadens the scope of definition to include all asbestos-coating materials containing fibrous silicates or mixtures of them [22,23,25], to which this paper subscribes. Asbestos mineral, in its naturally occurring state, is found in veins of rocks, consisting of bundles of fibers held firmly together to form solid rocks [19]. When mined and processed, it takes the form of very small fibres which are usually invisible to the naked eye. Mechanical milling processes break the fibers away from each other, leaving free finer fluffy fibers [21]. Fiber diameters, which could be smaller than a micrometer and without any detectable odour or taste [16], is reported by lukaz [26], to be 1,200 times smaller than a strand of human hair. Coupled with friability and airbone characteristics, the fibres become versatile in the built environments, hence, a well acknowledged health hazard agent [27].

ACMs have been known for over 2000 years [21,25]. Usage of ACMs increased remarkably during the industrial revolution due to its beneficial properties (Table 1), including high tensile strength and resistance to fire, heat, acids, and seawater [14,21]. These unique characteristics make ACMs useful in homes and industries; applicable in friction products, distribution pipelines for hot water and other liquids, fire-heat or noise-resistant walls in low-cost housing, roofing tiles, ceiling tiles, thermal insulation in furnaces, pipe insulation, protective clothing, electrical insulation and liquid filtration [17]. Its common use in Ghana has been in the area of building and construction as floor and ceiling tiles, roofing sheets, asbestos cement, water pipelines, corrugated paper pipe wraps, acoustical and decorative insulation, pipe and boiler insulation and spray-applied fireproofing [26].

| Serpentine Group of Asbestos | Characteristics | Applications |

|---|---|---|

| Chrysotile White asbestos | The only asbestos mineral in the serpentine group | It is suitable for fire resistant suits or gloves |

| Chrysotile accounts for approximately 95% of asbestos found in buildings in Europe North America | Chlor Alkali diaphragm membranes used to make chlorine | |

| Has a sheet or layered structure. | Drywall, joint compound, Caulk and plasters | |

| White asbestos has “curly” fibres. This property allows it to be woven | Stage curtains, Gas mask filters | |

| Mud and texture coats | ||

| Vinyl floor tiles, sheeting, adhesives | ||

| Roofing tars, felts, siding, and shingles | ||

| Transite panels, siding, countertops &pipes | ||

| Popcorn ceilings, also known as acoustic ceilings | ||

| Industrial and marine gaskets, Brake pads & shoes | ||

| Fire proofing, blankets, Interior fire doors | ||

| Fireproof clothing for firefighters | ||

| Thermal pipe insulation, drilling fluid additives | ||

| Filters for removing fine particulates from chemicals, liquids and wine | ||

| HVAC flexible duct connectors# | ||

| Amphibole Group of Asbestos | Characteristics | Applications |

| 1. Amosite Grey/brown asbestos | Has straight harsh grey to brown fibres. | Low density insulating board (often referred to as AIB or asbestos insulating board) and ceiling tiles; |

| Often used where additional strength is required such as high temperature asbestos pipe insulation as well as heat resistance such as fire rating. | Asbestos-cement pipe (ACP) | |

| Heat resistance such as fire rating | Asbestos-cement sheets and pipes for construction, casing for water and electrical/telecommunication services | |

| Thermal and chemical insulation (e.g., fire rated doors, limpet spray, lagging and gaskets) | ||

| Has fine straight blue fibres | Air conditioning plants, boilers, cooling towers, escalators, lifts and piping | |

| 2. Crocidolite Blue asbestos | Used in situations where acid resistance is required | Micronite filter in Cigarettes |

| Common material for fire rating of steel structural beams | ||

| Essential component in plant parts |

Table 1: Key mineral classification of Asbestos [16,50].

Harington and McGlashan [16] categorize asbestos into two main groups based on the crystalline structure of the mineral: serpentine and amphibole as outlined in Table 1. Serpentines have a sheet or layered structure whereas amphiboles have a chain like structure [16,17].

Relationship between ACMs Exposure and Health Risks in the Workplace

ACMs are present in both the natural and built environments. As a result, exposure to unregulated ACMs, either at home or in the workplace, presents ill-health hazards [7,10,28]. If damaged and exposed asbestos fibres are disturbed, they become airborne, which could be inhaled into the lungs [28,29]. Overtime, accumulation of fibres in the human system may result in a number of diseases, of which known ones, include asbestosis (a scarring of the lung tissue caused by asbestos), mesothelioma, asbestos related lung cancer and diffuse pleural thickening (a non-malignant disease affecting the lung lining [5,15,28,30-33].

International and National Agencies for Research on Cancers and Industrial Hygiene have tagged asbestos as a definite human carcinogen, based on sufficient evidence of carcinogenicity in humans [34-36]. Although most asbestos-related diseases have been linked to working directly with ACMs [37,38], WHO, Allen et al., Järvholm & Burdorf and Mudarri [3,10,30,39] have reported on many documented instances where asbestos exposure and subsequent development of health effects are attributed to the presence of ACM in environments where the work was performed. In the United States of America (USA), where perceived conflicting information on asbestos related cancers thrived prior to the turn of the millennium [40], today, enough scientific evidence exists on mesothelioma and lung cancer [14,28,41], laryngeal cancer [4,42], pharyngeal, stomach and colorectal cancers [14,28], all of which are associated with asbestos contaminated working environments.

Risk factors: Friability and smoking

For ACMs to pose health risks, airborne fibres must be generated, either through material degradation or high mechanical energy actions [22]. The potential for ACMs to release breathable fibers, to a large extent, depend on its degree of friability [14,43]. Friability, in this study, is explained to mean the ease with which ACM can be crumbled, pulverised or reduced to powder by hand pressure when dry and is therefore likely to emit or release fibers [2,44]. Further, HSE identifies fluffy sprays on materials used for fireproofing, insulation or sound proofing to be other types of materials considered to be friable. ACMs containing vinyl floor tiles or asbestos containing sealants, on the other hand, are described as non-friable [2,22]. These do not emit or release fibers unless subjected to mechanical energy operations such as sanding or sawing operations [14,43]. In this category, cement pipes or sheets containing ACMs, for example, can emit or release airborne fibers if the materials are cut or sawed or if broken up in demolition operations [24,45]. Non-bonded asbestos fabrics could also be in powdered form. The degree of friability and hence inhalation is, in part, dependent upon the matrix materials binding the asbestos, its general condition and the product type [14,43,45-47]. The highest health risks are associated with exposures to the amphibole group (amosite and crocidolite) with the latter being cited as the ACM of greatest concern [5]. Chrysotile (a serpentine mineral) is considered to be of a lesser but still significant concern [48]. Smoking has a supra-additive effect in increasing the risk of lung cancer in those exposed to asbestos. Scientific studies [4,33,49] have shown increased risk of lung cancer among smokers exposed to asbestos, compared to non-smokers, although such documented data is limited in developing economies [21,50].

Why the brewery industry?

Not until the mid-1980s when ACMs in Europe and the USA had been banned from workplaces, most people did not know brewing facilities were high-risk environment for asbestos exposure. Brewery filters contained asbestos [51,52]. The facilities were not different from many other industrial factory settings where asbestos was everywhere at the time. Filtration is a principal step in making beer [53,54]. The best beer batches are reported [53-55] to be highly-filtered to remove unsightly sediments and harmful microorganisms. This leaves them clean and safe for consumption. Blending asbestos fibers into cotton beer filters was considered a perfect solution because it is stable when blended with other products and contains exactly the right size of fibers to let liquid through, yet filters impurities [53]. Besides, asbestos was widely available, easy to work with and economical to a source [53]. Aside filtering, asbestos was widely used in brewery industrial settings. Materials that have been historically known to contain asbestos in brewery facilities include: Thermal system insulation, vinyl asbestos floor tile, wall and ceiling plaster, roofing materials, bearing pads, brake pads, expansion joints, sealants and paper products [19,56]. In this study, sprayed coatings, pipe insulation and Asbestos Insulating Board (AIB) were identified as the most dangerous material due to high ACM content and potential friability. However, a major drawback to using asbestos in breweries is when it becomes old and dry; it becomes fragile, hence friable [57]. With most breweries using hundreds of filters daily, unprotected workers were constantly exposed to a toxic environment, as handling asbestos filters releases tiny particles into the air [53]. Such workers become vulnerable to inhalation of asbestos fibers from beer filters and insulation laggings. Others who do not directly handle ACMs may have secondary asbestos exposure from breathing asbestos-contaminated air that flow throughout the brewery; others include maintenance staff who handled products during shut downs and even management staff walking on the floor. According to Reed, brewery workers exposed to asbestos stand a high risk of the deadly disease mesothelioma with a ten (10) to forty (40) year latency period. It is therefore possible that any unprotected worker in a contaminated brewery workplace before the 1980s is a mesothelioma victim in waiting. Asbestos beer filters, since the early 1980s, have been replaced by environmentally friendly materials (EFMs) [53].

Besides, the choice of the study area was also influenced by the following reasons; (i). The brewery industry is an emerging economic venture embraced by many households in Ghana with high prospects; (ii). Brewery products (alcoholic and nonalcoholic) are highly patronized by the masses; (iii) Although the use of ACMs in brewery facilities is either completely banned or highly regulated in the developed economies for health and safety reasons [14,50], its use is on the rise in developing economies [14] where regulations are poorly enforced or non-existent. Many buildings in the brewery facilities were constructed before the 1980s and still contain ACMs [12,18] and (IV). Most workers and duty-holders are unaware of the presence of ACMs in their working environment and its health implications, with a relatively longer latency period of 10-40 years.

Materials and Methods

This study employed a cross-sectional field survey design method. Approval to carry out the survey was obtained from the Ethics and Institutional Review Board (EIRB) at Central University. Permission was sought from management of the brewery company for their facilities and workers to be subjected to investigations and questioning.

Sample area

The brewery facilities under study (BFS-Accra and BFN-Kumasi) belong to an international brewery group of companies with a subsidiary in Ghana that employs hundreds of workers every year. Due to the sensitive nature of the investigations and confidentiality, details on site layout, nature of the building facilities, the construction type, details on the architectural drawings for individual buildings, details of plant, machinery and equipment and the span of the facilities were deemed critical and not disclosed by duty-holders. The BFS-Accra facility is situated in the capital city with a population close to four (4) million [58] and serves the whole of Southern Ghana. The BFN-Kumasi facility is approximately 248 km north of the capital city with over two (2) million population [58], serving the Northern sector of Ghana.

Survey procedure

The survey procedure employed the standardized consistent stepwise approach [7,59-61] in accordance with the HSE’s Control of Asbestos regulations [57], the Guidance on licensed asbestos removal work [22], the Analysts’ guide for sampling, analysis and clearance procedures [59], and Ghana’s EPA Guidelines on handling hazardous substances [20]. This method took the form of both interior and exterior visual inspections of facilities in only reasonably safe and accessible areas. First, a walk-through survey from ground level was conducted to determine the scope of inspection, which mapped out the facility sites into identifiable zones for material sampling (6 zones in BFN-Kumasi and 7 zones in BFS-Accra). Second, physical “hand pressure” test was conducted to determine friability conditions of suspected or presumed ACMs. Direct observable and suspected ACMs were sampled and documented on a chain-of-custody form for laboratory analytical test. Finally, air samples were taken to determine concentration of asbestiform fibers on the same mapped out zones.

Sampling procedures and analysis

Sampling was conducted in only accessible areas within the mapped-out zones with a coring tool (knife) designed to make clean cores of materials and to avoid creating excessive dust in the facilities. As per the HSG264 [23] and HSG248 [22] requirements, sample collection sites were pre-wetted to reduce fiber generation during the sampling process. Where instances of ACMs appeared to be extensive, only representative samples were taken for analysis. Samples from floor debris were also collected. In all, 38 samples from 42 locations in BFN-Kumasi and 101 samples from 43 different sites in BFS-Accra were taken. Individual materials sampled were placed in plain-labeled and self-sealable polythene bags and conveyed to a laboratory accredited by the Ghana Standards Authority (GSA) for analysis.

Air samples

Area air samples were taken in five (5) different locations in BFSAccra and six (6) locations in BFN-Kumasi, according to HSE 2006, Guideline HSG248 [22] to monitor levels of friable asbestos and air concentration of asbestiform fibres. It involved drawing known flow rate of air through a filter for a measured time so that airborne particles are collected. Based on HSE and Burdett et al. [22,62], the filter was then prepared for microscopical examination. A known fraction of the filtered deposit (480 litre sample, 200 graticules) was examined using X 500 phase contrast microscopy (PCM) to count all fibres seen (particles >5 μm long, <3 μm wide and a length to width (aspect ratio) of >3:1) in the graticule areas [63]. The calculated total number of fibres collected on the filter was divided by the volume of air sampled to determine the fibre concentration in terms of fibre per millilitre of air (f/ml) using the airborne concentration (C) formulae; [C=1000 N D2/V n d2, where; N is the number of fibres counted; n is the number of graticule areas examined; D (mm) is the diameter of the exposed filter area; d (μm) is the diameter of the Walton-Beckett graticule; and V (litres) is the volume of air sampled] [25,62,64,65].

Level of ACMs awareness in the brewery industry

The questionnaire method and focus group discussions were used to extract information from workers and duty holders in the brewery industry to assess their level of knowledge in ACMs in the workplace. Relevant data on ACMs in the workplace was obtained from both primary and secondary sources [66]. Primary data emerged from focus group interactions, key informant interviews and questionnaires. Based on Cochran [67], a total of 54 respondents (N=122) from both sites (BFN-Kumasi, BFS-Accra) were sampled using simple random and purposive methods. Respondents include general managers (n=2), environmental health and safety officers (n=2) and factory workers (n=50), as depicted in Table 2. On the ordinal scale, respondents were asked if they ‘strongly agree’, ‘agree’, ‘not sure’, ‘disagree’ and ‘strongly disagree’, to the following statements respectively; (a). ‘There is a strong presence of ACMs in your workplace’, (b). ‘You do not have prior information on hazardous materials, including ACMs) in your workplace’, (c). ‘ACMs are hazardous and could impact on health when exposed’ and (d). ‘Occupational health related diseases among long serving employees in your workplace could be related to exposures to ACMs’. All questionnaires (Rr=100%) sent out were retrieved for analysis. It comprised 35 (64.8%) males (21 from BFS-Accra, 14 from BFN-Kumasi) and 19 (35.2%) females (12 from BFS-Accra, 7 from BFS-Kumasi). Although a majority of the workers (38.9%) fall within age bracket 33-40 years, 10% were within 18-25 years and 10% were found to be above 45 years, with the frequency of appearance skewed towards males. All respondents have had some formal education with the highest level being tertiary (51.8%), followed by senior high secondary school/vocational/technical (48.1%). Respondents have worked in the facilities for various periods, spanning from not<5 years to ≥ 20 years (Table 2).

| Criteria | Respondents | ||||

|---|---|---|---|---|---|

| Sex | Male | Female | Total | % | |

| Age (Yrs) | Category | ||||

| 18-25 | 8 | 2 | 10 | 18.5 | |

| 26-33 | 9 | 4 | 13 | 24.1 | |

| 34-41 | 12 | 9 | 21 | 38.9 | |

| ≥ 42 | 6 | 4 | 10 | 18.5 | |

| Total | 35 | 19 | 54 | 100 | |

| Brewery facility sites | Male | Female | Total | % | |

| BFN-Kumasi | 14 | 7 | 21 | 38.9 | |

| BFS-Accra | 21 | 12 | 33 | 61.1 | |

| Total | 35 | 19 | 54 | 100 | |

| Level of Education | Frequency | Years worked | Frequency | ||

| Primary | 0 | > 5 | 11 | ||

| Middle/JHS school | 5 | 6-10 | 17 | ||

| SHS/VOC/Tech | 21 | 11 -15 | 11 | ||

| Tertiary | 28 | 16-20 | 9 | ||

| ≥ 20 | 6 | ||||

| Total | 54 | 54 | |||

Source: Field data, 2017

Table 2: Workers’ socio-demographic data.

Limitations of survey inspections

Although this is a visual non-destructive asbestos study, efforts were made to identify all ACMs in the facilities, together with basic items of plants and equipment. Therefore, there is warranty, expressed or implied to the completeness of this survey. Locations of ACMs in concealed areas in the facilities where investigators could not access were identified, marked and recorded without implementing destructive sampling techniques. This approach was adopted with the assumption that it is only friable ACMs that pose risk to workers. However, when the facilities are undergoing renovation or demolishing exercises, maintenance workers could easily locate areas containing ACMs from records. These include; wall cavities and internal pipe work penetrations in solid walls and concrete floor slabs, integral parts of machinery, plant and pipe works, fire dampers and reheat units within air conditioning ducts, boilers and inaccessible service ducts and risers. Samples were also not taken in locations envisaged to place inspectors at risk of injury or death. They were inspected to be in equally good conditions. Maintenance workers were only cautioned to protect themselves when dealing with the locations. Such high-risk asbestos ACM areas include; internals of electrical switchboards, air conditioning ductwork, internal construction elements such as plumbing or electrical risers/conduits, rooftops, some offices, store rooms and substations. For these reasons the survey results only indicate the presence or otherwise of ACMs as were found in the course of the research over the period. The findings should not be solely relied upon without taking into consideration the specific limitations and scope of the survey undertaken.

Results and Discussion

Bulk material analysis

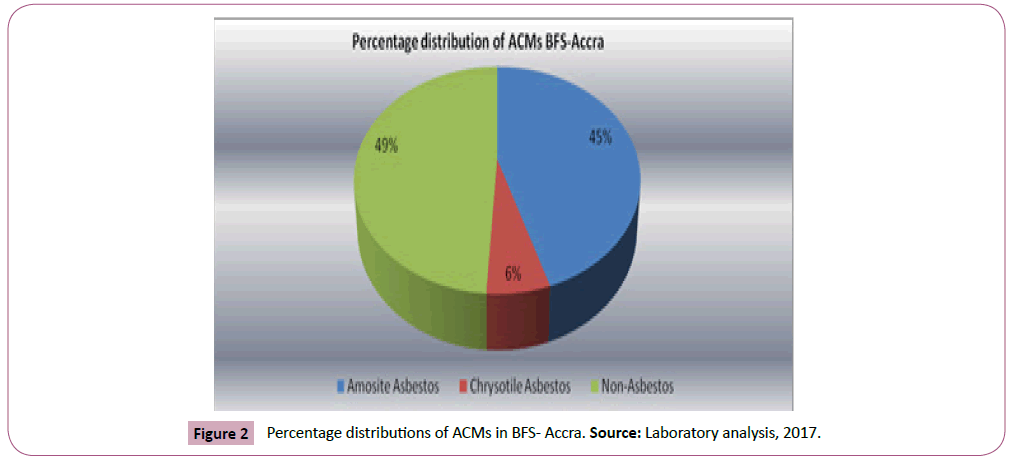

Laboratory analysis of bulk materials sampled from the southern sector (BFS-Accra), positively confirmed 45% of the ACM distributions to be amosite asbestos fibres from 21 sites and 6% chrysotile asbestos fibres from 3 sites. 49% of the distribution samples from 19 sites, as shown in Figure 2, however, did not indicate any presence of ACMs (N=101).

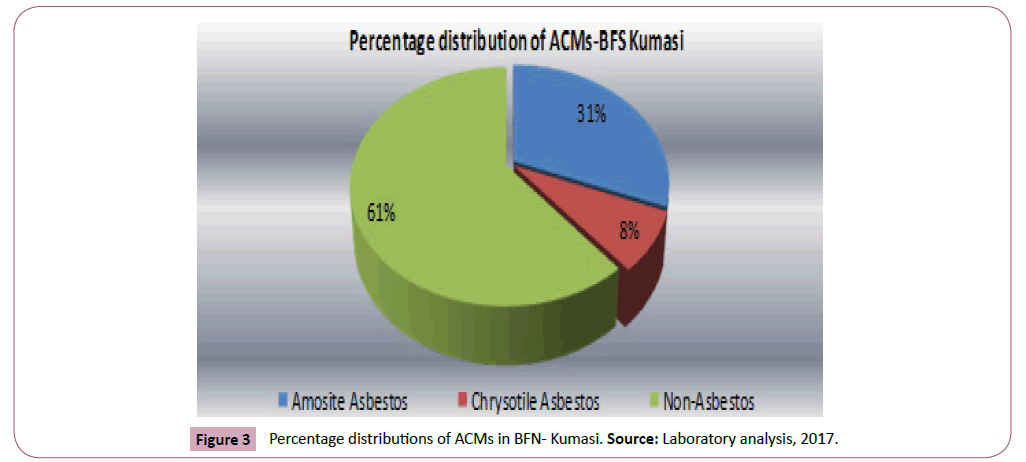

In the Northern sector (BFN-Kumasi), out of 38 bulk samples taken, 14 samples, confirmed presence of ACMs, in the form of amosite (31%) and chrysotile (8%) fibres. The remaining 24 samples, representing 61% did not indicate any presence of asbestos fibres (Figure 3).

Material assessments in the two facilities did indicate considerable amount of ACMs distribution presence (Figures 2 and 3). Amosite asbestos fibres were found on exposed steam pipes in the Brewing house, on Utilities lines, Cellars, Offices and Packaging areas. Chrysotile asbestos fibres were found in roofing materials at the car parks, administrative blocks and offices and in gaskets used for flange maintenance at the packaging departments. Other ACMs identified were in the form of gaskets, fire blankets (in the administration, stores and kitchen), brake shoes (main stores) and building materials such as fibro sheeting and pipe work and tiles. ACMs were not found on beer filters.

Air sample analysis

Air sample analysis, summarily outlined in Table 3, all returned negative results. According to Burdett and Le Guen et al. [62,65], absence of air concentration of asbestiform fibres does not, however, eliminate risk potential of asbestos fibres being released into the environment, especially as known ACMs (amosite, chrysotile) were confirmed, with some exposed and in deplorable state. Significant disturbances could put these fibres into the environment.

| Sample location | Sample ID | Concentration of Asbestiform fibres per millimeter of air (f/cc) | Concentration of Asbestiform fibres |

|---|---|---|---|

| Area sample | BFN-Kumasi | C<1 | |

| Fumehood (FH) | Air 6- FH | 0.01 | None present |

| Boiler 3 | Air IV - SWP 8 Bar | 0.01 | None present |

| Scent Area | Air – IV | 0.01 | None present |

| CIA | Air II | 0.01 | None present |

| MFA | Air I | 0.01 | None present |

| MFA | Air III | 0.01 | None present |

| Area sample | BFS-Accra | C<1 | |

| Brew house | MT/MC | 0.01 | None present |

| Cellars MLT | MLT 301 | 0.01 | None present |

| Packaging | L8 BW | 0.01 | None present |

| Packaging | PSSL | 0.01 | None present |

| Utilities | BCTII | 0.01 | None present |

Source: Laboratory analysis, 2017

Table 3: Air concentration of asbestifirm fibres.

Awareness of ACMs presence in the workplace

Respondents’ level of knowledge of ACM presence in the workplace was assessed by eliciting responses from workers to 4 questions/statements listed in the first column of Table 4. Age was significantly associated with the level of education (P<0.05). Respondents were to ‘agree’ or ‘strongly agree’, ‘disagree’ or ‘strongly disagree’ to or state ‘not sure’ to the questions/ statements outlined (Table 4). The level of education was also significantly associated with the level of awareness on ACMs in the workplace (P<0.01). These are workers who are considered matured enough, per the age brackets ≥ 18 ≥ 42, and have worked for periods ranging from ≥ 5 ≥ 20 years (Table 2). Seventy-point four percent (70.4%) of the respondents (Table 4) were either ‘not sure’ (9.3%), ‘disagree’ (20.4%) and ‘strongly disagreed’ (40.7%) to the independent variable, ‘strong presence of ACMs in the workplace’, although laboratory analysis proved otherwise (Figures 2 and 3). This may be attributed to lack of knowledge on the part of workers on ACM presence in their working environment as WHO, Rice and Rake et al. seem to suggest [7,14,15,68-70]. Only 40.7% of respondents had ‘prior information on hazardous materials’, including ACMs in the workplace. The rest either ‘disagree’ (13%), strongly disagree to (18.5%) or were ‘not sure’ (27.8%) of responses to the questions/statements as they had no prior knowledge on hazardous substances in the workplace.

| S. No. | Awareness of ACMs in Brewery Facility | Strongly Agree | Agree | Not Sure | Disagree | Strongly Disagree |

|---|---|---|---|---|---|---|

| 1 | There is strong presence of ACMs in your workplace | 4 (7.4%) | 12 (22.2%) | 5 (9.3%) | 11 (20.4%) | 22 (40.7%) |

| 2 | You do not have prior information on hazardous materials, including ACMs) in your workplace | 13 (24%) | 9 (16.7%) | 15 (27.8%) | 7 (13%) | 10 (18.5%) |

| 3 | ACMs are hazardous and could impact on health when exposed | 3 (5.5%) | 7 (13%) | 28 (51.9%) | 9 (16.6%) | 7 (13%) |

| 4 | Occupational health related diseases among long serving employees in your workplace could be related to exposures to ACMs | 2 (3.7%) | 7 (13%) | 29 (53.7%) | 10 (18.5%) | 6 (11.1%) |

Source: Field data, 2017

Table 4: Level of awareness of ACM’s presence in the workplace.

With only 18.5% in agreement, majority of respondents were ‘not sure’ (51.9%), ‘disagree’ (16.6%) and ‘strongly disagree’ (13%) to the statement, ‘ACMs are hazardous and could impact on health when exposed to. Opinions expressed on the relationship between exposure to ACMs and chronic occupational related illhealth in the workplace returned similar pattern of responses as only 16.7% ‘agree’ (13%) or ‘strongly agree’ (3.7%) to this assertion. With a confidence level of 95%, there was significant evidence (p>0.02) to confirm the proposition that the level of awareness of ACM’s presence in the brewery facilities among workers was very limited.

Total Material Assessment Score (TMAS)

Based on HSG264, the material assessment algorithm (MAA) was used to calculate TMAS for all ACMs identified or presumed to be present in the workplace as outlined (Appendix A and B) [23]. The TMAS is defined as the average sum scores of the sample variables; Pt + Ed + StT + At, where TMAS is total material assessment score, Ed is extent of damage, StT is surface type/treatment and At is asbestos type [22]. Maximum score of a sample variable is 3 and maximum average sum score of the TMAS is 12. Per the standards, HSG264 [23], total material assessment scores which fall within category A (>10) have a very high potential, category B (7-9) have high potential, category C (6-8) have low potential and category D (3-5) have very low potential to release ACM fibres if disturbed. From Appendix A and B, the material assessment score established the BFS-Accra facility as having comparatively, very high potential of releasing fibres (6 ≥ TMAS=12).

Risk Priority Action Score (RPAS)

Based on HSE, the priority action score (PAS) is the summation of four variables; normal occupant activity (Noa) + likelihood of disturbance (Lod) + human exposure potential (Hep) and maintenance activity (Ma), with a maximum value of 3 points each [45]. PAS is added to the TMAS (12) to give the total overall maximum risk priority score (RPS) of 24. From the register (Appendix A and B), field results and interpretation of the overall priority action scores are depicted in Table 5.

| Priority Code | RPAS | Risk Level | Interpretations and recommended actions |

|---|---|---|---|

| 1 | ≥ 18 | High risk | Manage ACM’s and carry out planned remedial action to reduce the risk score, typically within 12 months or less, to below risk score 18 in accordance with facility Asbestos Policy and Management Plan. |

| 2 | 12-17 | Medium risk | Manage as priority code ‘1’s, but remedial action may be deferred until maintenance regimes change, or demolition or major refurbishment is planned. |

| 3 | ≤ 11 | Low risk | Manage and consider removal if the item falls within a demolition or major refurbishment area and works is likely to disturb the material. |

Based on HSE, 2012d

Table 5: ACM Risk Priority Action Score (RPAS).

Conclusion and Recommendations

Sampling and laboratory analysis of ACMs in the brewery facilities identified substantial quantities of amosite (BFN-Kumasi, 31%; BFN-Accra, 45%) and relatively smaller quantities of chrysotile (8% BFN-Kumasi; 6% BFN-Accra), as insulation materials on pipelines, machinery and plant parts in the brew house, utilities sections, packaging sections, administration offices, in the kitchenette and generator house. The remaining samples (24 from BFNKumasi; 19 from BFS-Accra) tested negative and did not indicate any presence of asbestos fibers. Samples were from coatings on ammonia steam pipelines, bright beer tank product outlet lines, alcohol return lines, chillers in the brew house, utilities, ammonia refrigerant lines, pasteurizers, packaging sections, clarifier compressors, effluent laboratory tiles, waste water treatment plants, engineering sections, high strength alcohol tank, water storage tank reservoirs gaskets and hammer mills.

Air samples, taken at sites in both locations, all returned results below permissible thresholds (C<1), confirming that as at the time of the survey, there were no airborne concentration of asbestiform fibers in the facilities. However, this does not eliminate the risk of asbestos fibers being released into the environment, especially as some of the confirmed ACMs were exposed and were in deplorable conditions. Any further disturbance could lead to friable asbestos fibers being released. There was significant evidence (p>0.02) to accept the proposition that the level of awareness of ACM’s presence in the brewery facilities is low as opinions expressed by a majority of respondents on statements listed in Table 4 on the level of ACMs awareness turned out to be either, ‘not sure’, ‘disagree’ or ‘strongly disagree’ to the questions/statements posed.

Once presumed or known ACMs have been identified, this study recommends to management of duty holders to translate survey results into asbestos registers for appropriate management and remedial measures. Per the risk priority actions prescribed for the total material assessment scores (Appendix A and B), all ACMs marked as being in good condition with a low potential to release asbestos fibers can be left in-situ and monitored regularly for any deterioration or damage with minimal risk. Those that are exposed, either in part or as a whole, should be enclosed immediately. In case of any future deterioration, they should be safely repaired. Their location should be recorded, and their existence made known to contractors, staff and others who may be affected. Warning labels advising of the presence of asbestos may be appropriate, together with periodic condition inspections.

All ACMs marked as medium, per the TMAS, should be repaired or encapsulated immediately. In the event that it is determined damaged beyond repair or the repair option is not practical, the ACM should be safely removed by authorized asbestos removal contractor(s). Their locations should be recorded, and their existence made known to the duty holder, contractors, staff and other stakeholders who may be affected. Access to areas containing asbestos in poor condition may need to be restricted until remedial measures have been completed. All the asbestos removal works should be carried out by a licensed asbestos contractor. Further, information from the survey could be used to prepare detailed asbestos registers on both facilities, showing the ACM locations. The registers must be available on-site either electronically or in hard copy format, available to the duty holder, workers and their representatives and all other stakeholders. Aided by the outcomes of the risk priority assessment scores, a complete management plan should be designed and implemented to ensure that ACMs on premises and sites are systematically and competently managed. The paper also recommends that extensive studies must commence immediately to establish the prevalence rate of workplace hazardous substances, related illhealth and deaths over the last three decades to inform health policy direction.

References

- Landrigan P (1998) Asbestos-still a carcinogen. N Eng J Med 338: 1618-1619.

- Nicholson WJ, Landrigan PJ (1996) Asbestos: A status report. Current Issues in Public Health 2: 118-123.

- World Health Organization (2017) Asbestos: Elimination of asbestos-related diseases. Fact Sheet N_343; World Health Organization: Geneva, Switzerland.

- Iliopoulou M, Bostantzoglou C, Nenna R, Skouras VS (2017) Asbestos and the lung: Highlights of a detrimental relationship. Breathe 13: 235-237.

- Sen D (2014) Working with asbestos and the possible health risks Occup Med1: 6-14.

- LaDou J (2004) The asbestos cancer epidemic. Environ Health Perspect 112: 285-290.

- WHO (2015) Asbestos use continues in Africa despite severe health warnings. WHO Regional Office, Congo, Brazzaville, Central Africa.

- Lin RT, Takahashi K, Karjalainen A, Hoshuyama T, Wilson D, et al. (2007) Ecological association between asbestos-related diseases and historical asbestos consumption: An international analysis, Lancet 369: 844-849.

- Raffaelli I, Festa G, Costantini AS, Leva G, Gorini G (2007) Mortality in a cohort of asbestos cement workers in Carrara. Ital Med Lav 25: 156-163.

- Allen LP, Baez J, Stern ME, George F (2017) Asbestos-economic assessment of bans and declining production and consumption. World Health Organization Regional Office for Europe, Copenhagen, Denmark.

- Mossman BT, Bignon J, Corn M, Seaton A, Gee JBL (1990) Asbestos: Scientific Developments and Implications for Public Policy. Science 247: 294-301.

- Castleman BI (2006) Asbestos is not banned in North America. Eur J Oncol 11: 85-88.

- Berry M (1997) Mesothelioma incidence and community asbestos exposure. Environ Res 75: 34-40.

- Rice J (2014) Asbestos and the globalization of an occupational and environmental hazard, 1960-2011. Environmental Justice 7: 1-8.

- Rake C, Gilham C, Hatch J, Darnton A, Hodgson J, et al. (2009) Occupational, domestic and environmental mesothelioma risks in the British population: A case-control study. Br J Cancer 25: 1175-1183.

- Harington JS, McGlashan ND (1998) South African asbestos: production, exports, and destinations, 1959-1993. Am J Ind Med 33: 321-326.

- Hart HP (1988) Asbestos in South Africa. J South Afr Inst Min Metall 88: 185-198.

- Yalley PP, Kwaw P, Ndede CN (2012) The continuous use of asbestos in ghana despite its hazards: A case study area: Sekondi-Takoradi. J Environ Sci Eng 2: 510-518.

- Van Gosen BS (2007) The geology of asbestos in the United States and its practical applications. Environ Eng Geosci 13: 55-68.

- EPA (2016) Hazardous and Electronic Waste Control and Management Act (ACT 917). Environmental protection Agency, Accra, Ghana.

- Mathee A, Von Schirnding YER, De Wet T, Mokoetle K (2000) Potential risk factors for asbestos exposure amongst six-month-old infants living in the township of Soweto, South Africa. Int J Environ Health Res 10: 135-139.

- HSE (2008) Asbestos essentials: A task manual for building, maintenance and allied trades on non-licensed asbestos work HSG210 (2nd edn), HSE Books.

- HSE (2012a) Guidelines for HSG264 Asbestos, the survey guide, HSE Books.

- HSE (2012b) Approved codes of practice and guidance L146 (2nd edn), HSE Books.

- Vaughan NP, Rooker, SJ, Le Guen JM (1981) In situ identification of asbestos fibres collected on membrane filters for counting. Ann Occup Hyg 24: 281-290.

- Jean-Lukaz YT (2006) Ghana: Asbestos to Be Banned in Ghana? Public Agenda Column, Accra, Ghana.

- Arthur LF, Joshi TK (2014) The global spread of asbestos. Ann Glob Health 80: 257-262.

- Cowie RL, Murray J, Backlake MR, Samet JM (2007) Occupational pulmonary disorders. Saunders Elsevier 23: 182-199.

- Pawelczyk A, Bozek F (2015) Health risk associated with airborne asbestos. Environ Monit Assess 3: 428-433.

- Jarvholm B, Burdorf A (2015) Emerging evidence that the ban on asbestos use is reducing the occurrence of pleural mesothelioma in Sweden. Scand J Public Health 43: 875-881.

- Dongmug K, Min-Seun K, Young-Ki K, Jong-Eun K (2013) Systematic review of the effects of asbestos exposure on the risk of cancer between children and adults. Ann Occup Environ Med 25: 10.

- National Comprehensive Cancer Network (2010) Clinical Practice Guidelines on Oncology, Milignant Pleural Mesothrlimona, London.

- Stayner LT, Wegman DH (1983) Smoking, occupation and histopathology of lung cancer: A case-control study with the use of the Third National Cancer Survey. J Natl Cancer Inst 70: 421-426.

- Constanza MC, Stayner LT, Straif K (2011) Occupational exposure to asbestos and ovarian cancer: A meta-analysis. Env Health Persp 119: 1211-1212.

- Huncharek M (1994) Asbestos and cancer: Epidemiological and public health controversies. Cancer Invest 12: 214-222.

- National Economic Development and Labour Council (NEDLAC) (2002) The Socio-Economic Impact of Phasing out Asbestos in South Africa, Johannesburg, South Africa.

- Institute of Medicine (2006) Asbestos: Selected cancers. Washington (D.C.) The National Academies Press, US.

- Lemen RA (2011) Epidemiology of asbestos-related disease and the knowledge that led to what is known today. (2nd edn). Dodson RF, Hammar SP, (ed). Asbestos: risk assessment, epidemiology and health effects. Boca Raton, FL: CRC Press.

- Mudarri DH (2014) National expenditures, jobs, and economic growth associated with indoor air quality in the United States. J Environ Health 76: 26-31.

- Texas Department of Health Services Report (1998) Health risk related to the use of asbestos. Texas, USA.

- Hodgson JT, Darnton A (2000) The quantitative risks of mesothelioma and lung cancer in relation to asbestos exposure. Ann Occup Hyg 44: 565-601.

- Chen M, Tse LA, Au RK, Yu IT, Wang XR, et al. (2012) Mesothelioma and lung cancer mortality: a historical cohort study among asbestosis workers in Hong Kong. Lung Cancer 25: 165-170.

- Naoum SG (2008) Dissertation Research & Writing Construction for Students. Butterworth Heinemann Press, London.

- HSE (2012d) Asbestos essentials: A task manual for building, maintenance and allied trades on non-licensed asbestos work HSG210 (3rd edn), HSE Books.

- HSE (2012c) Medical Guidance Note: Guidance for doctors on the Control of Asbestos Regulations 2012: Medical surveillance for workers carrying out non-licensed work with asbestos Medical Guidance Notes.

- Van Oyen SC, Peters S, Alfonso H, Lin Fritschi L, De Klerk NH, et al. (2015) Development of a Job-Exposure Matrix (AsbJEM) to Estimate Occupational Exposure to Asbestos in Australia. Ann Occup Hyg 59: 737-748.

- Wagner GR (2007) The fallout from asbestos. Lancet 369: 973-974.

- HSE (1996) Consulting workers on health and safety. Safety Representatives and Safety Committees Regulations 1977 (as amended) and Health and Safety (Consultation with Employees) Regulations 1996 (as amended).

- Frost G, Darnton A, Harding AH (2011) The effect of smoking on the risk of lung cancer mortality for asbestos workers in Great Britain, 1971-2005. Ann Occup Hyg 55: 239-247.

- Virta RL (2006) Worldwide Asbestos Supply and Consumption Trends from 1900 through 2003. U.S. Geological Survey Circular 1298. Reston, VA, USA.

- Watterson A (2012) Economic costs of ARDs. In Proceedings of the Human and Financial Burden of Asbestos in the WHO European Region, Meeting Report, Bonn, Germany, Annex 5. pp. 53-67.

- Wood D (2003) Asbestos: Days of future past. Australian and New Zealand Institute of Insurance and Finance.

- Reed RJR (1986) Centenary Review Article Beer Filtration. J Inst Brew 92: 413-419.

- Beckett MH (1985) Master Brewers Association of the Americas. Technical Quarterly 22: 53.

- Bernstein L (1974) Master Brewers Association of the Americas. Technical Quarterly 11: 198.

- Frost G, Harding AH, Darnton A, McElvenny D, Morgan D (2008) Occupational exposure to asbestos and mortality among asbestos removal workers: A Poisson regression analysis. Br J Cancer 25: 822-829.

- HSE (2013) Managing and working with asbestos: Control of Asbestos Regulations HSE L143 (CAR) 2012.

- Bahk J, Choi Y, Lim S, Paek D (2013) Why some, but not all, countries have banned asbestos. Int. J Occup Environ Health 19: 127-135.

- CAR (2006) Asbestos in system buildings: Control of Asbestos Regulations 2006. Guidance for Dutyholders. HSE 2008.

- ILO (2011) Guidelines for the use of the ILO International Classification of Radiographs of Pneumoconiosis, Geneva, Switzerland.

- WHO (2005) WHO STEPS Surveillance Manual: The WHO Stepwise approach to the chronic disease risk factor surveillance, Geneva, Switzerland.

- Burdett JG, Rood AP (1983) Membrane filter, direct transfer techniques for the analysis of asbestos fibers or other inorganic particles by transmission electron microscopy. Environ Sci Technol 17: 643-648.

- James KR, Bull TB, Fox B (1987) Detection of asbestos fibres by dark ground microscopy. J Clin Pathol 40: 1259.

- Rooker SJ, Vaughan NP, Guen JML (1982) On the visibility of fibers by phase contrast microscopy. Am Ind Hyg Assoc J 43: 505-515.

- Le Guen JM, Rooker SJ, Vaughan NP (1980) A new technique for the scanning electron microscopy of particles collected on membrane filters. Environ Sci Technol 14: 1008-1011.

- Berkelmann RL, Stroup DF, Detels R, Holland WW, McEwen J, et al. (1997) Public health surveillance. In Omenn, G.S., (Ed). Oxford University Press, UK. 3: 735-750.

- Cochran WG (1963) Sampling techniques. In: Statistical Surveys. Grebenik, Moser CA, (Ed). New York.

- Glica M, Sobczyk W (2014) Waste containing asbestos in the community Szczucin. Inzynieria Mineralna 15: 97-104.

- WHO (2010) World Health Organization Statistical Information System (WHOSIS).

- WHO (2016) Assessing the economic costs of the health impacts of environmental and occupational factors: The economic dimension of asbestos. In: Proceedings of the Conference, Bonn, Germany.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences