Polymer Congress 2018

Polymer Sciences

ISSN: 2471-9935

Page 69

June 04-05, 2018

London, UK

4

th

Edition of International Conference on

Polymer Science and

Technology

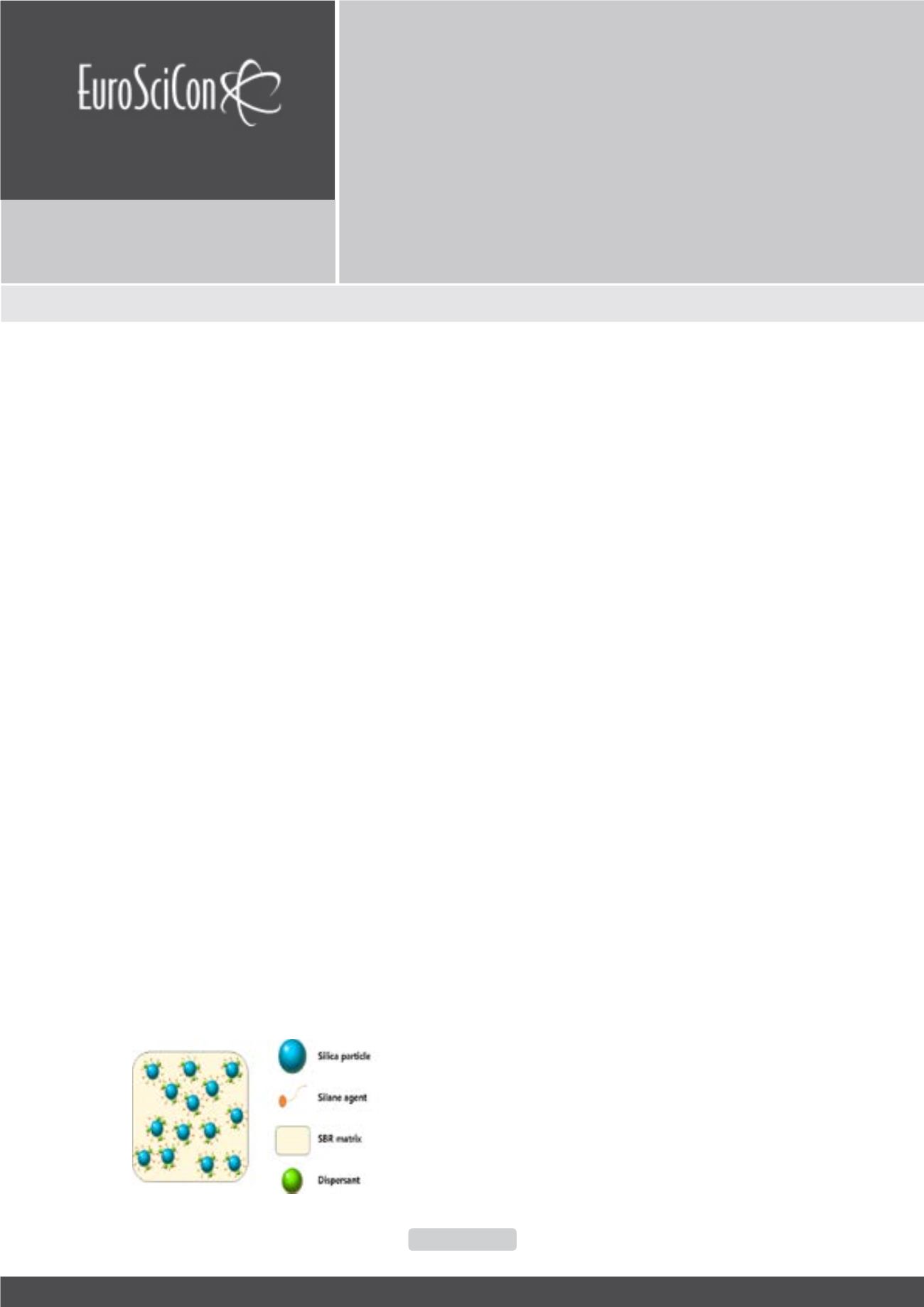

T

he higher silica content in the tire-tread rubber can

maximize the efficiency of the vehicle. However, silica

does not mix well with other mixtures, including the tire-tread

rubber. This phenomenon deteriorates the various properties

of the tire-tread rubber. Therefore, we have tried to improve

the dispersity of silica in tire-tread rubber by using dispersant.

The dispersion of silica in tire-tread styrene-butadiene rubber

(SBR) is one of important factors in the mechanical properties

of it. We prepared dispersants to enhance silica content and

dispersity in SBR using wet master batch (WMB) system. The

dispersants were prepared by copolymerization of styrene with

allyl alcohol or methyl methacrylate. The synthetic conditions

of dispersants were changed to improve the silica loading

content and dispersity in WMB system for the preparation of

silica-SBR composites. The WMB system was consisted of

the steps involving dispersants synthesis, silica modification,

dispersion of modified silica in SBR emulsion latex, and

coagulation of silica-SBR composites. We confirmed the

structure of the dispersants using FT-IR. The content of silica in

the composites was measured by thermal gravimetric analysis

(TGA) according to the types of dispersants. We also studied

the payne effect with rubber process analyzer (RPA) instrument

and dynamic viscoelasticity with Dynamic mechanical analysis

(DMA) instrument. We measured the mechanical properties of

them such as tensile strength and modulus of M300. We found

the optimal types and content of dispersants for silica-SBR

composites.

Recent Publications

1. Bourgeat Lami E, Espiard Ph and Guyot A (1995) Poly

(ethyl acrylate) latexes encapsulating nanoparticles

of silica: 1. functionalization and dispersion of silica.

Polymer. 36.23:4385-4389.

2. Choi Sung Seen, Park Byung Ho and Song Hanjong

(2004) Influence of filler type and content on properties

of styrene‐butadiene rubber (SBR) compound

reinforced with carbon black or silica. Polymers for

Advanced Technologies. 15.3:122-127.

3. Choi Sung Seen, Nah Changwoon and Jo Byung

Wook (2003) Properties of natural rubber composites

reinforced with silica or carbon black: influence of

cure accelerator content and filler dispersion. Polymer

International. 52.8:1382-1389.

4. Yan Gui et al. (2016) Preparation and performance

of silica/SBR masterbatches with high silica loading

by latex compounding method. Composites Part B:

Engineering. 85:130-139

5. Byeongho Seo et al. (2013) Characterization of AN-

SBR/Silica compound with acrylonitrile as a polar

group in SBR. Macromolecular Research. 21(7):738-

746.

Biography

Byeongkwan Kang is currently pursuing Master’s Degree in Chemical

Engineering at Hanyang University, Republic of South Korea. He is

also working at Korea Institute of Industrial Technology (KITECH). Our

company research Institute of Industrial Technology Convergence leads

Industry Convergence Technology and explores future growth engines to

drive the economy by developing and commercializing intelligent robots,

high-tech medical fibers, ultra-precision nanotechnology, wellness

systems, and packaging technology. He is mainly interested in polymer

chemistry such as hydrogel.

90kbk@kitech.re.krB K Kang et al., Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-012

The silica dispersing effects of silica-SBR composites with

dispersing agent: poly(styrene-allyl alcohol) and poly(styrene-

methyl methacrylate)

B K Kang

1

, M S Kim

1

, J S Kim

1

, Y W Chang

2

and

D H Kim

1

1

KITECH, Republic of South Korea

2

Hanyang University, Republic of South Korea