Polymer Sciences

ISSN: 2471-9935

June 04-05, 2018

London, UK

Polymer Congress 2018

Page 36

4

th

Edition of International Conference on

Polymer Science and

Technology

Phenomenological Review of LCP/PET Droplet

Fibrillation by Repeated Extrusion for

Nanofiber Formation

Han-Yong Jeon

INHA University, South Korea

L

CP(Liquid Crystal Polymer) is a high strength polymer

which shows characteristics that are the rigid main chain

and molecule’s arrangement which has directivity. LCP and

PET blending is noted in the blend. Because of they have the

similar melting temperature and structure. In the LCP and

PET blending, the droplet size and dispersion are important

point. Therefore understanding of the droplet behavior is very

important for the after process. In case of the blended chips

supply to make product, once more the chips are extruded

from the extruder. So droplet control in the repetitive extrusion

is important. But until now, the droplet behavior analysis

was not conducted in the repetitive extrusion. Also, droplet

behavior change by extrusion number of times was observed

that in the process of analysis on blending condition and

weight ratio. The droplet behavior change is supposed that

relate with flow property, miscibility, surface property of LCP

and PET. If nanofiber is manufactured depending on LCP,

there is every possibility of utilizing in a higher value-added

industry. Although there are some processes to produce

nanofiber such as electricity spinning and sea-island type, it

still has difficulties that electricity spinning has a low output

and sea-island type is restricted to reduce fiber diameter. It

will be effective to solve the existing problems as mentioned

above that if material of droplet shape is able to become

consecutivefibermorphology through stretchingprocess.The

research that deal with making continuity through the way to

regulate size of droplet has not yet been achieved in existing

dissertations of manufacturing of fibers related to droplet

stretching method. This study is planned to verify control

of droplet via study of its behaviors that are influenced by

repetitive extrude LCP and PET blend substance and confirms

size changes of droplet while it is extrude repeatedly. These

changes show size growth according to increase number

of extrusion and changes of droplet’s location are checked

as well. Distributions of droplets were observed to LCP and

PET blending process for conjugate spinning. Droplets were

distributed relatively evenly in the initial extrusion process.

But the secondary and third the size of the droplet was

increased and the phenomenon was founded that the droplet

was gathered in the center. This phenomenon was assumed

that the miscibility of LCP/PET and the flow characteristics

correlate with the phenomenon, so conducted the analysis. In

this study, to analyze distribution and component of droplet

was conducted. Also miscibility of LCP/PET was analyzed.

Recent Publications

1. C.H. Song and A.I. Isayev, LCP droplet deformation

in fiber spinning of self-reinforced composites [J],

Journal of Polymer, 2001, 42(6) : 2611-2619

2. W.N. Kim and M.M. Denn, Properties of blends of a

thermotropic liquid crystalline polymer with a flexible

polymer(Vectra/PET) [J], Journal of Rheology, 1992,

36, 1477-1498

3. W.G. PERKINS, The Effect of Blending Temperature,

Composition, and Shear Rate on PET/Vectra A900

LCP Blend Viscosity and Morphology [J], Journal of

Applied Polymer Science, 43, 329-349

Han-Yong Jeon, Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-010

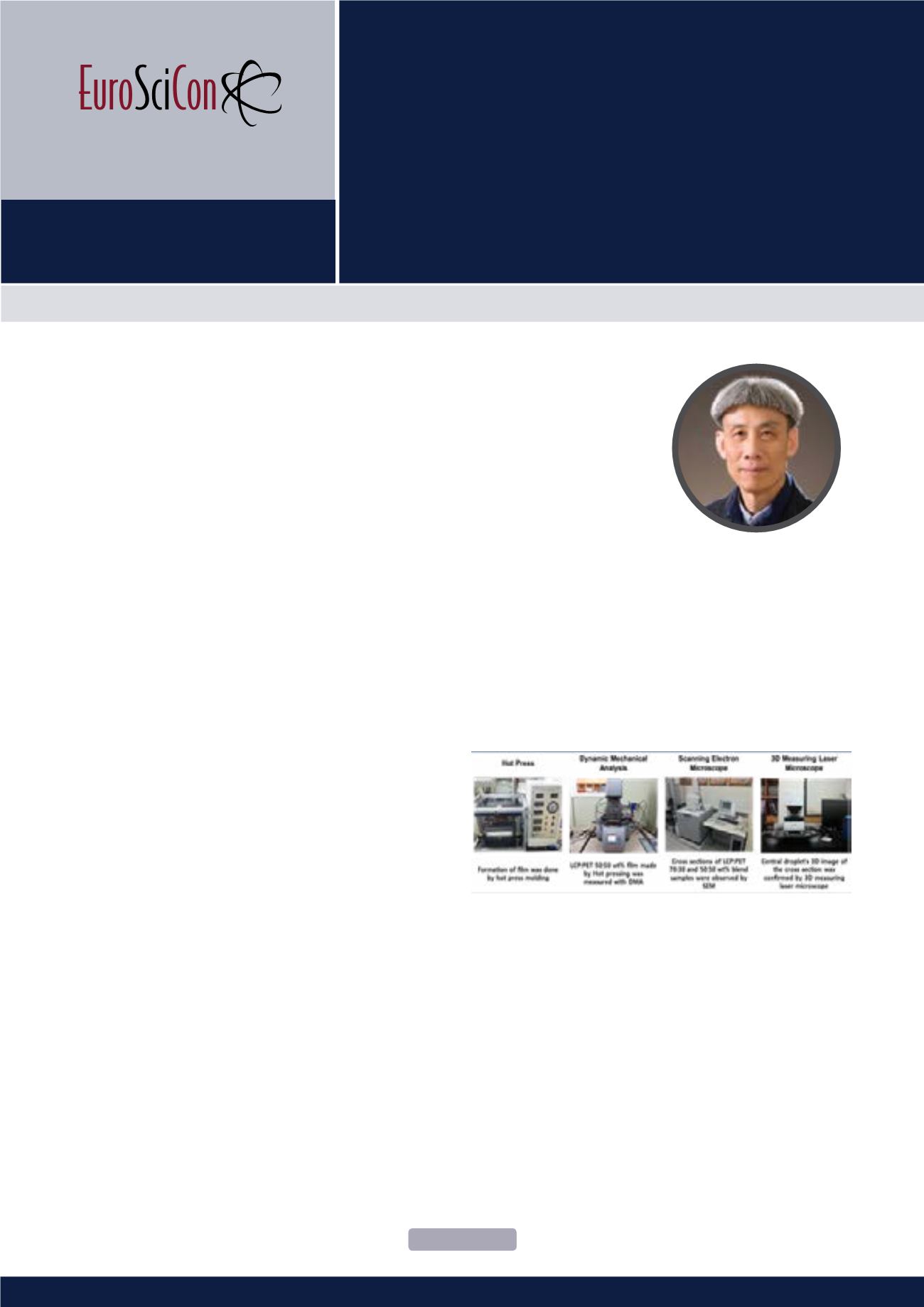

Figure 1:

Test equipment for LCP/PETdroplet behaviorby repeated extrusion