Polymer Sciences

ISSN: 2471-9935

June 04-05, 2018

London, UK

Polymer Congress 2018

Page 18

4

th

Edition of International Conference on

Polymer Science and

Technology

M

aintaining flow in the production and transportation of

crude oil is a critical challenge in both on-shore and

off-shore environments. Problems such as wax deposition

and flow restriction from gelling can occur with changes

in temperature and pressure during production, as well

as changes in crude oil composition when oil streams are

combined. Traditionally, solvent, thermal and mechanical

methods have been used as wax remediation treatments.

However, chemical treatments are now increasingly

employed to mitigate flow assurance problems caused by the

naturally occurring paraffins in crude oil. Due to the unique

composition of every crude oil, there is no single product

capable of treating all flow assurance problems. An acrylic

comb polymer has been developed as a dual Pour Point

Depressant (PPD) and Wax Inhibitor (WI). A PPD lowers the

temperature at which wax crystals form a network which gels

and solidifies the oil and a WI reduces the amount of wax

which is deposited on pipe walls and other surfaces. This

polymer has a strong PPD and/or WI effect in several crude

oils yet its mode of action is not fully determined. Cross

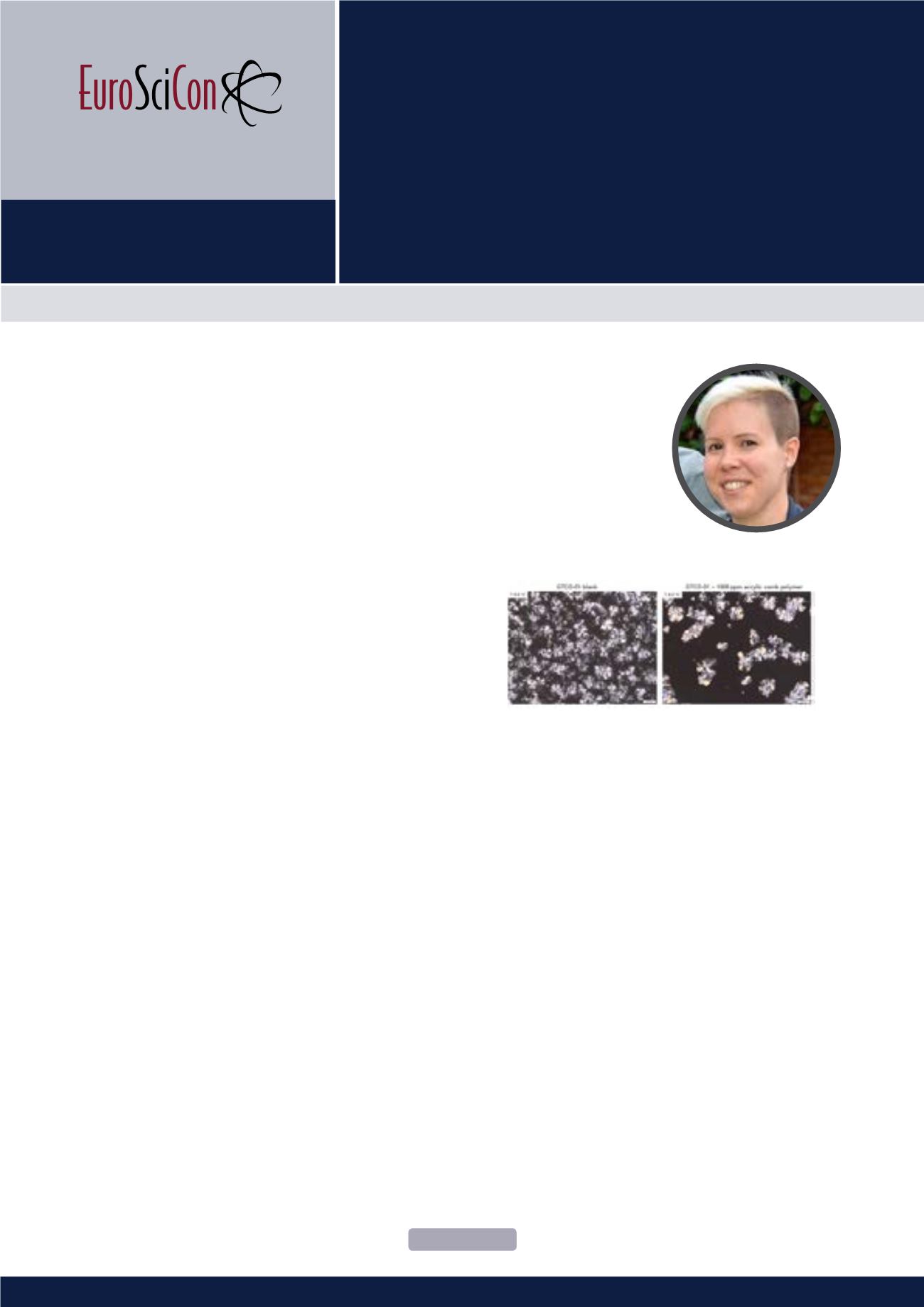

Polarized Microscopy (CPM) was used to observe the effect

of the polymer on wax crystal morphology in several crude oils

and to shed light on the mechanism of Pour Point Depression

and Wax Inhibition. Early results suggest that the polymer

modifies the structure of the wax crystals, making them less

angular and less dispersed throughout the oil. It is possible

that this reduces the ability of the wax crystals to form a

network and gel the oil, or to deposit on metal surfaces. This

material also displays a range of other properties and results

which makes it an attractive solution to wax challenges in

cold flow applications.

Recent Publications

1. Davies C et al. (2013) The development and field

application of new surfactant chemistries for

applications to heavy oils. Society of Petroleum

Engineers. Pages:10.

Biography

Jessica Gould gained her PhD in Synthetic Inorganic Chemistry under

the supervision of Professor Martin Schröder at The University of Not-

tingham. She currently works as a Lead Research Scientist at Croda

Europe Ltd specializing in the development of acrylic polymers for a

wide range of applications from Personal Care to Battery Additives.

Since joining Croda in 2013 she has developed a wide range of exper-

tise in synthesis of new products focusing on tailored dispersants and

rheology modifiers.

jessica.gould@croda.comrThe effect of an acrylic polymer wax control

additive as a cold flow solution for wax

challenges

Jessica Gould

Croda Europe Ltd, UK

Jessica Gould, Polym Sci 2018, Volume 4

DOI: 10.4172/2471-9935-C2-010

Figure 1:

A visual comparison of thewax crystals in an Asian crude oil (with andwith-

out polymer). Details of crude oil: Pour Point=39°C, API=33°, Wax AppearanceTem-

perature=54°C.Themost common chain lengths in thewax profile are C20 to C35.